These Carbon Fiber Wheels Might Be the Coolest Part of the C8 Corvette Z06

After years of rumors, speculation, and spy photos, the 2023 Chevy Corvette Z06 is finally here. While the 670-hp flat-plane V-8 might be the car's main attraction, the Z06 has a ton of other impressive upgrades that make it worthy of the name. The coolest? Probably the carbon fiber wheels.

Available as an option on the Z07 package, these five-spoke, one-piece wheels aren't designed by Chevrolet. Instead, their creation is outsourced to Carbon Revolution, an Australian firm that launched the world's first ever production carbon fiber wheel—designed to fit onto a 997-generation Porsche 911 GT3—all the way back in 2013. The company has since been contracted by Ford to build carbon fiber wheels for the Mustang Shelby GT350R, Mustang Shelby GT500, and the company's GT supercar.

Measuring 20 inches by 10 inches up front and 21 inches by 13 inches out back, the C8's wheels are the tallest and widest set ever produced by Carbon Revolution. While exact weight specs have yet to be released, the company claims a weight savings of over 41 pounds, or a roughly 40-50 percent reduction, versus the standard forged aluminum wheels—a massive number considering it's all unsprung weight. They also have the highest load capacity of any wheel Carbon Revolution has designed so far. Buyers will have two choices of finish: a clear coat option that exposes the carbon weave or a painted version called "Carbon Flash."

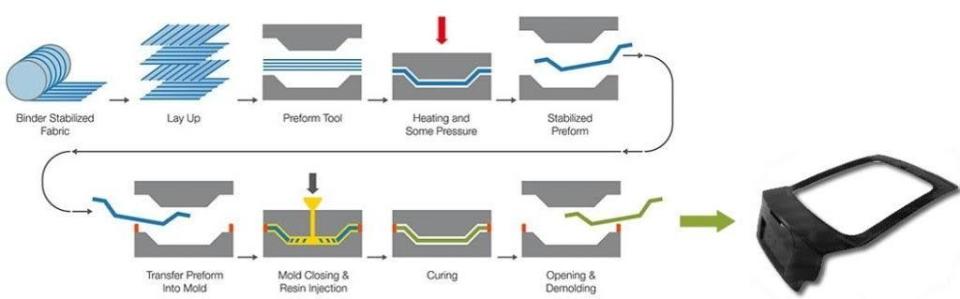

Though the five-spoke design may look fairly simple, making the Z06's carbon fiber wheels is an incredibly complex ordeal. In a process Carbon Revolution calls high-pressure resin transfer molding, the company starts by creating what it calls a "dry wheel" by laying down carbon fiber sheets in layers before heating and pressurizing it to solidify the design. From there, the wheel is placed in a mold and subjected to extremely high pressures to extract any air that may be trapped inside. It's then injected with resin using an incredible 700 psi of pressure. The resulting high temperatures are what cures the resin into a solid piece, locking the carbon fiber sheets into place and creating the ultra-strong, ultra-lightweight finished product.

These wheels are the result of a five-year collaboration between Chevrolet and Carbon Revolution engineers that included R&D, design, and validation testing. Carbon Revolution says the hardest part about going from idea to reality was forming the shape of the spokes. Here's how it approached the challenge:

Carbon Revolution solved [this problem] by how it positioned the layers of fabric relative to one another and how the years of fabric overlap each other at the transition from the spoke to the rim, and vice versa.

Unique to the Corvette wheel is that the five-spoke design drove Carbon Revolution to incorporate the ‘ski jump,’ which is a solid carbon feature that diagonally connects the front of the spoke laminate with the back of the spoke laminate. It has the effect of increasing the wheel’s performance while maintaining a big weight savings. The Corvette Z06 wheel is the first production wheel with this feature.

The materials and the production process aren't the only cool things about the Z06's carbon wheels. Like many OEMs, Carbon Revolution now turns to virtual analysis tools to simulate vehicle conditions and incidents such as hard cornering, pothole strikes, or speed bumps, to test out its wheels. This accelerates the testing and validation processes, driving down costs.

You Might Also Like

Yahoo Autos

Yahoo Autos