These $83K Australian Prefabs Are Built to Withstand Bushfires

Designed with cross-laminated timber, Fabprefab’s Minima home is available in eighteen different configurations with more options for custom touches.

Welcome to Prefab Profiles, an ongoing series of interviews with people transforming how we build houses. From prefab tiny houses and modular cabin kits to entire homes ready to ship, their projects represent some of the best ideas in the industry. Do you know a prefab brand that should be on our radar? Get in touch!

Fabprefab was founded in 2016 by Tony Olding. Across his 30-plus years of experience in construction, he saw the industry beset by problems like material and labor shortages, construction delays, and rising building costs—not to mention the large amounts of waste and high carbon emissions associated with traditional construction. Tony sought to address these problems by manufacturing homes in a controlled environment. Just outside of Sydney, his solar-powered facility uses cross-laminted timber (CLT) to manufacture twenty-five off-the-shelf models designed in collaboration with Trias Studio and CHROFI Architects.

We asked Fabprefab’s managing director, Ed Callanan, to walk us through their latest project and what’s in store for the company.

What’s the most exciting project you’ve realized to date?

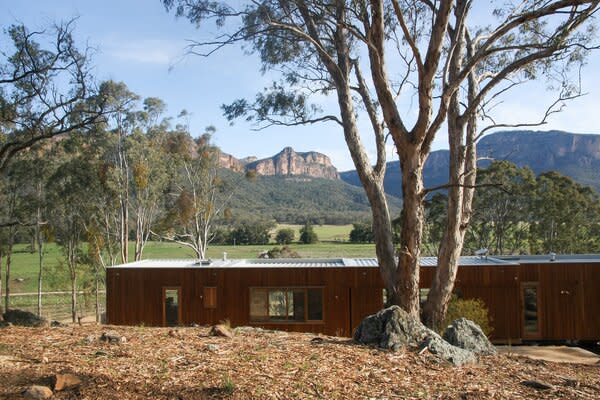

We recently utilized our Minima modular design as a template for a full-sized house located in the Capertee Valley, in Wiradjuri Country in the western Blue Mountains, New South Wales, Australia. The site is in a stunning location on the edge of the World Heritage-listed Wollemi National Park, with an impressive outlook across rugged sandstone cliffs and eucalyptus forests. It’s also in a bushfire zone.

The project, Practice Ground, is a two-bedroom, two-bathroom dwelling constructed on a narrow footprint that allows for uninterrupted views of the surrounding landscape from every room in the house. The building is comprised of four separate modules, all constructed from plantation radiata pine CLT panels that were completely assembled in our factory and delivered to the site on four separate trucks. Then it was craned into place over two days. The house is clad in sustainably sourced blackbutt, and Australian hardwood, which was a custom addition that provides for increased bushfire protection.

The clients were a young couple who were looking to build their first home on the property. They both have careers that require significant travel and wanted a part-time residence as a place to relax and unwind with friends and family, and where they could work from when required. The clients wanted the house that engaged with the surrounding landscape, and had a reduced environmental footprint.

The clients came to us after some challenges with a traditional design and construction process. The remoteness of the property made it difficult to find a local builder to take on the project, with the travel required for contractors to get to site adding significant cost and complexity. The clients didn’t want to compromise on design or quality, so they were looking at prefabrication as an alternative approach to achieve a sophisticated design that was sympathetic to the adjacent landscape, but at a reasonable cost.

See the full story on Dwell.com: These $83K Australian Prefabs Are Built to Withstand Bushfires

Related stories: