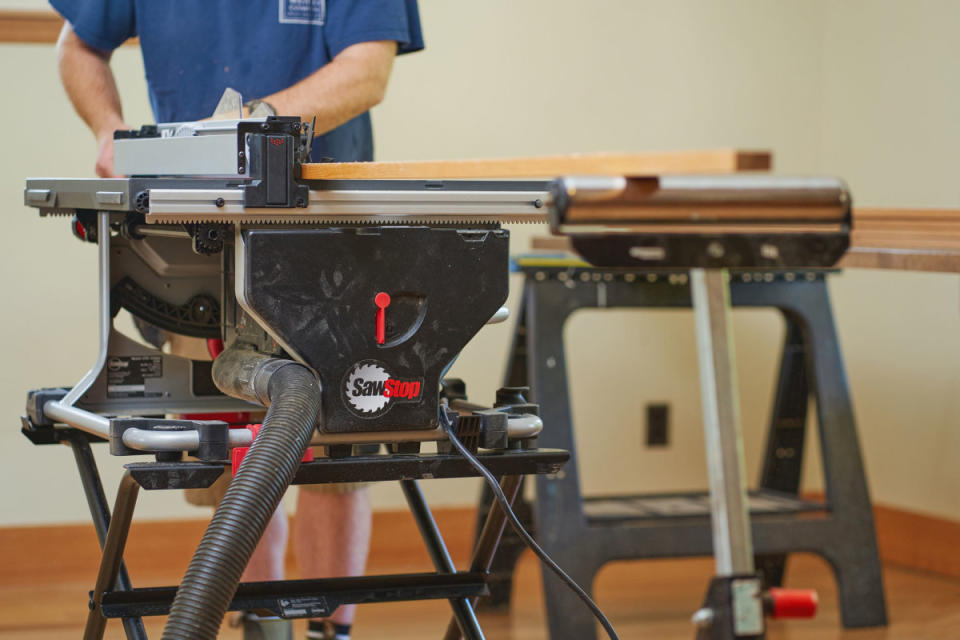

This is the Safest Table Saw for DIYers

Table saws cause at least one estimated blade-contact injury every nine minutes as well as thousands of amputations annually in North America. Household tool brand SawStop has patented technology that looks to change that. Finally, years of advocating and action appear to be influencing the United States Federal Consumer Product Safety Commission (CPSC) to mandate a blade braking system to reduce blade-contact injuries from table saws. As a user of power tools including table saws, the severity of blade injuries cannot be understated. If you're choosing a new tool for a hobby, DIY home improvement project, or professional purpose, look beyond the price tag and pay attention to the safety features. Beyond traditional blade guards, there's something to be said about this intelligent technology.

“Since we began, here at SawStop we have been focused on protecting Woodworkers and helping them work better through practical innovation,” said SawStop CEO Matt Howard. AIM-equipped table saws with aluminum brake springs look to raise the safety standards for table saws, and other types of saws, too.

SawStop

How SawStop AIM Works

SawStop's products, including its newest 10-inch compact table saw, are outfitted with a unique Active Injury Mitigation (AIM) system. While the tool delivers all the power and precision you expect, its safety technology has proven to save digits and limbs in the workshop.

The blade detects conductive material. The patented safety feature uses a small electrical signal in the rotating saw blade to detect conductive material, such as human skin.

Upon detection, the tool stops. The motor of the tool immediately shuts off, and an aluminum blade brake enters the path of the spinning blade, bringing it to a near-immediate halt.

The blade drops into the table. The angular momentum from spinning effectively drops the now-still blade into the base of the table saw, eliminating the risk of additional cutting injuries.

The user resets the tool. In less than two minutes, the user can inspect the blade, replace the brake cartridge, and get back to work.

Why doesn't wood set off this safety system?

Simply put, wood is not conductive to electricity, so it doesn't trigger the spinning saw blade to brake.

Related: How Much Oil Should You Mix With Gas For Small Engine Tools?