'We want to show what can be done': Surfers craft board out of trash, Colectivo bags

NEW BUFFALO, MICHIGAN - Ken Cole prepared to seal what he called the aesthetic part of his project — a surfboard made primarily of Colectivo coffee bags and palm leaves.

He called it the sealing of a coffin. Just before they laid down the belly of the board, he and Ted Burdett, a fellow surfer, paused.

"Wait, we have to write something inside," Cole said, wanting to bring and share a message for when the board finally hit the waves. "What do we write?"

"A secret surf spot?" Burdett suggested. "Should we Chat GPT, 'What should I write in a bio-based surfboard?'"

Cole pondered this for a few minutes before he popped the cap off a black Sharpie and wrote on the tail of the board: "Our Environment. Our Responsibility."

It's a testament to the last five years of work Cole and others have put into bringing this board to life. As the world looks for alternatives to the toxic or harmful materials that many goods are currently made of, Cole wanted to be a spark of inspiration within and outside the sport that connect him most to nature.

There's no guarantee prototype number one will be the answer to the use of unsustainable materials for surfboards and other products. But, that's not why he pursued this project.

"We just want to show what can be done. That in and of itself is a statement," Cole said. "When I tell people we made a surfboard out of leaves, they assume we glued a bunch of leaves together. They don't understand the engineering behind it by a rag tag group of creative visionaries without any guarantee this would work. Just to prove it can be done. We hope it'll get more shapers to think, 'what else can be done?'"

A new vision for boards

When Cole moved to Wisconsin, he brought that surfing background with him and even started shaping boards as a side business in late 2018. From the start, his mission with Greenhouse Surfboards, which operated out of a workshop in the Harbor District, was to make sustainably-minded surfboards.

That proved difficult. From the outside though, you might never know. The exterior of his boards used sustainable materials like jute, hemp, bioresin, basalt and repurposed wood. The jute gave his board a recognizable look because it came via Colectivo coffee bags. The logo could be seen on many boards.

The problem was the interior. That, like most modern, non-wooden surfboards, was made with polyurethane foam. The material is highly useful when it comes to board shaping and surfing itself due to its light weight and buoyancy, but the petroleum-based product is not sustainable and is actually toxic to the environment.

"From the outside, my boards looked amazing and were as green as it gets, but 95 percent of the board was this foam," Cole said. "The more I read about these materials, I realized, as a surfer, I was a hypocrite. When I'm out in the water, I'm pushing this stuff out and standing on the one thing that's increasingly getting banned across the globe."

After one last board in 2021, Cole stopped shaping. Instead, he studied and educated himself about sustainable materials and practices. A good starting point was a material he discovered at a summer backyard party in 2019. The host used plates and utensils made of palm leaves. They were strong, sturdy — and sustainable.

He dug through his neighbor's trash to take some home.

Combining the palm leaves with jute from coffee bags he used to wrap his surfboards, he created a sort-of prodigal border plywood, minus the wood. It was things you could just pick up off the ground with a significantly smaller carbon footprint.

Breakthroughs came when others got involved, especially from within the surf community. Enter Michael Sevier, a fellow Milwaukee surfer and assistant professor of mechanical engineering at the Milwaukee School of Engineering. Their conversations led to consultations with Sevier and another MSOE assistant professor, Kevin Hart. They both had strong backgrounds and interests in sustainable materials and designs.

Together, they tested composites, shared data on similar existing materials and even turned the idea of making a sustainable surfboard into two senior design projects at MSOE. The groups are currently creating two boards: one made of jute and one made of mycelium mushrooms.

They tested the strength material with different designs like a skateboard and a bench made of the jute-leaf composite. Over five years, other people have come into the project to offer their own expertise and ideas, but one of the biggest breakthroughs came when Burdett, an industrial design professor at the University of Illinois-Chicago, joined the team in 2023.

Making the board

Burdett was working on his own project about Great Lakes surfboards, Great Lakes Surf Craft Project (GLSCP), which focuses on boards shaped for the Great Lakes, when he met Cole. While he commissioned some boards, Burdett asked Cole if they could work on the board together. Bringing an industrial design background to the table, the two began working together in early 2023.

"It's what's going to happen with pretty much every product that's built, consumed or used," Burdett said. "It's maybe crazier that everybody else is stuck in a traditional way of doing things, but maybe you have to be a bit kooky to go out and say you're going invent a new away to do it. But that's what's needed."

Using the dimensions and design of Cole's original boards, Burdett created a mold to make the rails out of jute. The nose and tail of the board needed to be a bit stronger, so they repurposed balsa wood that they carved on a CNC router. For the deck and belly, they created a skin made of jute and bioresin.

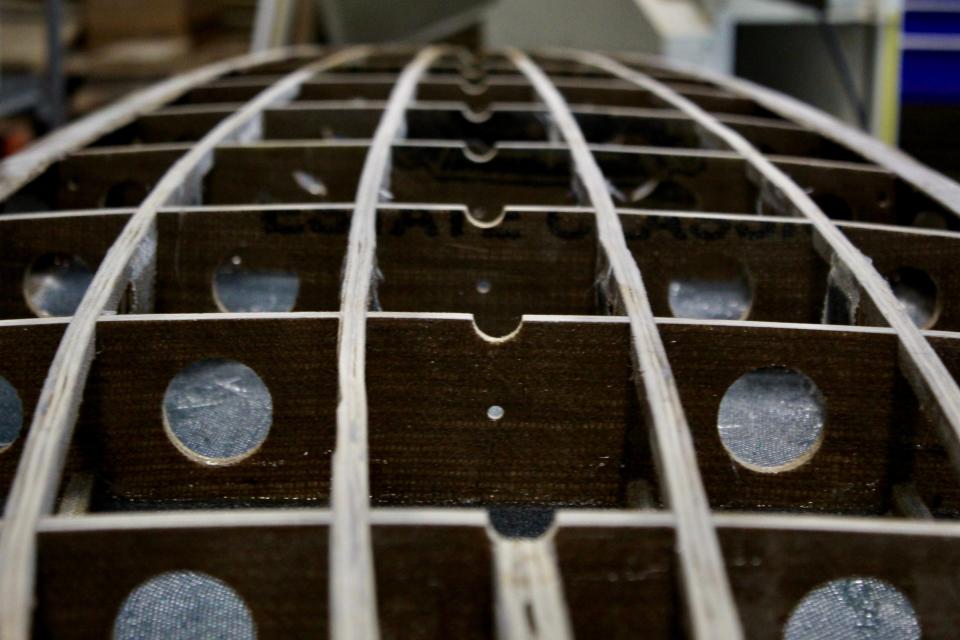

In the center is a unique element. Using the plywood created with jute, palm leaves and the bioresin, Burdett and Cole created a skeleton inside, an idea that came from unexpected sources.

"We're borrowing from surf construction, but more from boat and airplane construction than what is typically done," Burdett said. "Typically for modern hollow surfboard, you're working from standard sheet marine plywood. You cut out slabs, cut solid pieces of it, but we save a huge amount of weight making it hollow because this composite is a heavy material."

After five years of playing around with the material, Cole's vision had finally come to life.

Time will tell

There's a balance to work on a passion project with another person. Cole and Burdett have gone back and forth to ensure their visions come alive in a way that doesn't harm the creative or engineering process. The board in front of them is the exact dimensions of the one Cole shaped and surfs with — a 9-foot-6 longboard.

Through give and take, they have a prototype. To ensure its waterproof, they sealed the inside, and that means hiding that skeleton with the belly.

With a composite of bioresin and wood flour, Cole and Burdett finally sealed the board shut. It becomes truly apparent that there is no blueprint to work from as they attach a few clamps and wrap the board with most of a roll of packing tape.

Yet, there it is. A surfboard made primarily of leaves and coffee bags.

"To the best of our knowledge, this has never been done before," Cole said. "It's a testament to collaboration, leaving your comfort zone, reaching out to folks that are like-minded and sharing skillsets. This is the board five years later."

Minimal work remains before its water ready. In two weeks, Burdett will deliver the board to Milwaukee. Cole will then do the final wraps with jute and the only non-sustainable material on the entire board: a volan cloth, which is fiber glass often used for boards. The decision to add this piece was to add a bit more strength and reduce the weight for the first test.

"It’s like 99.9 percent better than other boards," Cole said. "This takes a lot of time and work, and it may not even result in anything. But, this is about the passion for what it’s trying to convey. The conversation is much, much more than making a surfboard out of leaves. It’s about being inspired and inspiring others. If we can make a board, what else can people make with this."

There's no guarantee the board will catch a wave. This is a one-of-one board that's never even been in the water before. Burdett said that there's a chance the board falls apart as soon as they try to stand up on a wave. But that's not what this mission is about.

"The board we've made is definitely a prototype," Burdett said. "Is it the most efficient way to make a surfboard? Definitely not, but we're learning really neat things along the way that, I think, are super practical and applicable to production of a great many things."

With the final touches impending, all that's left to do is wait for the right winds to bring a solid line up on Lake Michigan. The hope is to try the board in the water in early spring. What they learn then, they plan to use for the next board.

"When stars align, we'll head out to South Beach in Port Washington and take it out for a perfect day," Cole said. "All we need is to ride one wave. Just one, and then we'll ride the next one."

This article originally appeared on Milwaukee Journal Sentinel: Milwaukee surfer spent years creating a sustainable surfboard