You'll Never Guess How Bomb Pops Are Made

If there's one image that defines summer, it's a sticky Bomb Pop melting down your hand. But have you ever wondered how the tri-color popsicles are made? How do the three different colors come together without mixing? How does the treat gets those grooves? I lived out my childhood dreams and visited the Bomb Pop factory to get a behind-the-scenes look.

Bomb Pops come from a one-million-square-foot factory in the ice cream capital of the world, Le Mars, Iowa. This is where Bomb Pop's parent company, Wells Enterprises, is headquartered. The company also make ice cream sandwiches, twist cones, Halo Top, and Blue Bunny ice cream, and uses about 114,000 gallons of milk everyday.

Wells acquired Bomb Pops in the 1990s from Merritt Foods. Before then, Bomb Pops were sold out of a truck. "My dad hated the Bomb Pop trucks," said CEO Mike Wells. "They drive their trucks up and down the street and ring the bells. We'd run out there with our money and buy Bomb Pops." You can still buy the popsicles from ice cream trucks, and the brand has added more varieties to the lineup since being acquired. Along with the original and sugar-free versions, there are now Nerds, Crush, Hawaiian Punch, Banana Fudge, Watermelon, Warheads, and Jolly Ranchers flavors.

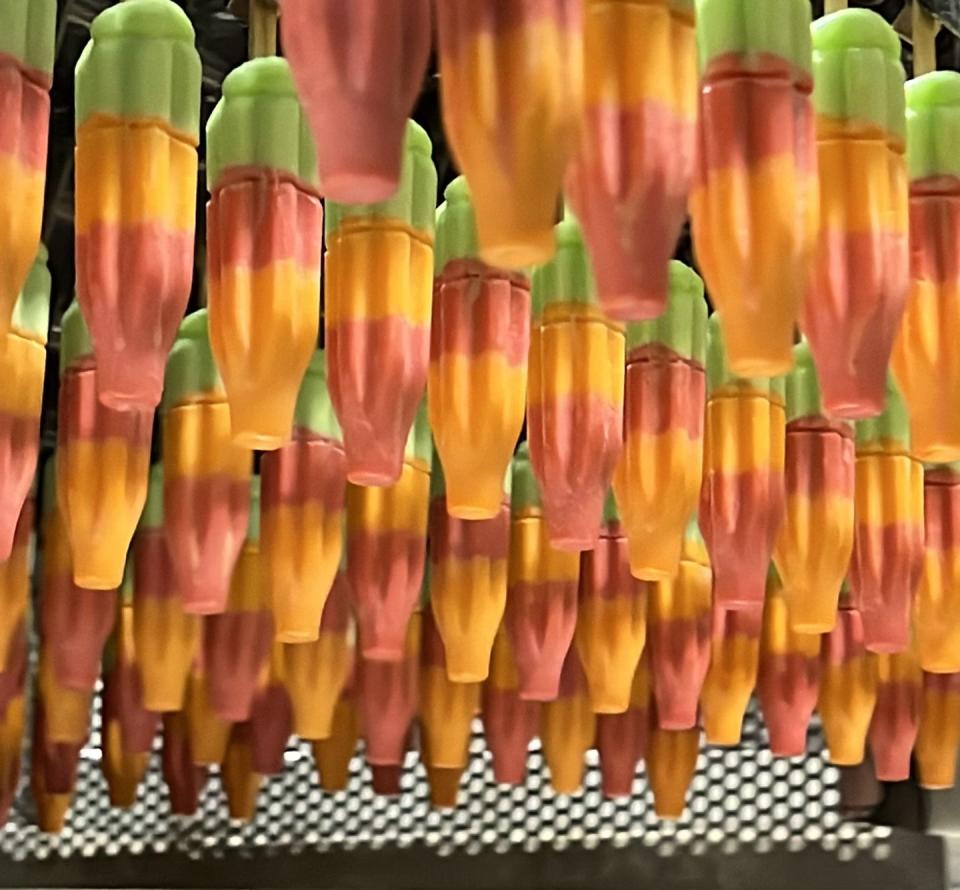

Back in Le Mars, you can immediately tell when you enter the factory's Bomb Pop zone. Your nostrils are filled with a fruity aroma that brings you right back to your childhood. And then you see them: rows and rows of colorful popsicles hanging upside down, moving from one station to the next.

On the day I visited, they were churning out Hawaiian Punch Bomb Pops made with the drink's Fruit Juicy Red, Green Berry Rush, and Ocean Orange flavors. It starts with a mixture of sugar, water, and stabilizers that is blended together and pasteurized. Color and flavor is added before being slush frozen.

The slushy syrup is then divided into the three flavors and piped into a rocket mold. The mold sits in a cold, salty brine that freezes the liquid immediately before the next layer is piped on top.

Then a machine pushes a popsicle stick into the frozen mixture. The molds are dipped into a warm brine just long enough for a machine to grab the popsicle sticks and pop them free. From there, the popsicles are dropped into a white plastic packaging, which is sealed. The wrapped pops are boxed up and sent off to the freezer.

But this isn't just any freezer. This is an enormous 12-story warehouse where all the products are frozen and stored before being shipped to stores across the country. The last step is you eating a Bomb Pop while its sticky syrup melts down your hand.

You Might Also Like