UPS Unifies Supply Chain Tools in One Dashboard

UPS is bringing its many supply chain service offerings—from shipping to warehousing to freight forwarding—under one roof with the introduction of the UPS Supply Chain Symphony portal.

America’s largest package delivery firm unveiled the solution Wednesday, the same day it cut the ribbon at UPS Velocity, a new 900,000-square-foot facility near Louisville, Ky. powered by automation, machine learning and artificial intelligence (AI).

More from Sourcing Journal

Drivers at UPS, FedEx, Amazon Fall Victim to Carjackings, Cargo Theft

Forward Air Countersues Omni Logistics, Wants Out of $3.2B Merger

UPS Supply Chain Symphony helps customers to operate more efficiently, gain better visibility into their supply chains and more effectively address supply chain challenges.

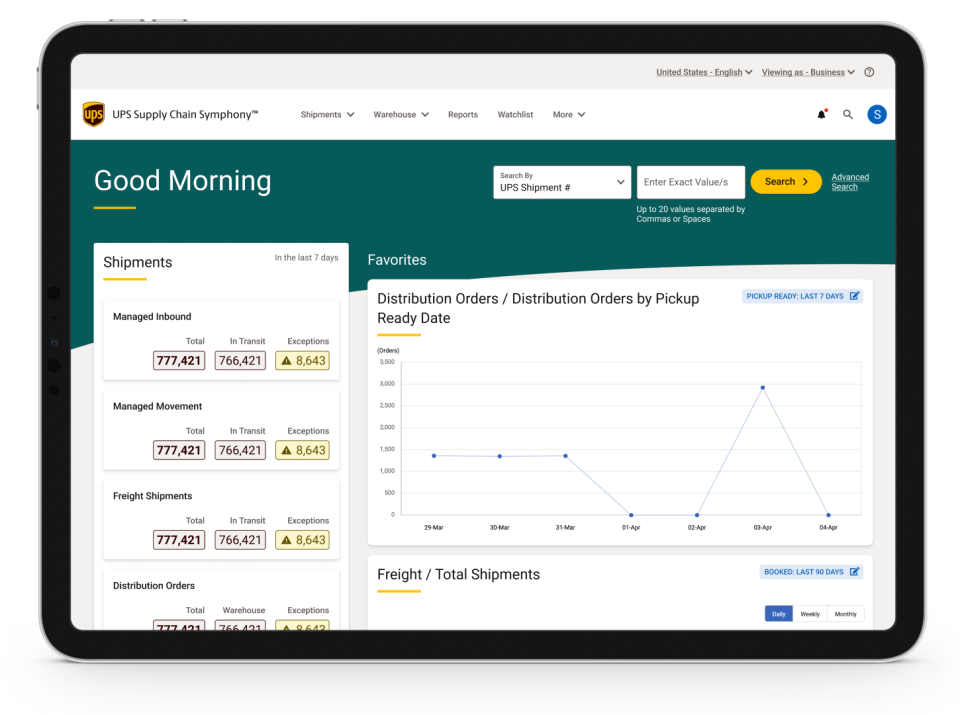

The Software as a Service (SaaS) solution provides a view of near-real-time UPS inbound and outbound information, including volume summary by warehouse location. Users can monitor order milestones, view inbound-outbound shipment details and track UPS-managed shipments to more easily measure performance. Order milestones show critical information from shipment creation to delivery.

The portal now integrates previously standalone tools across the UPS ecosystem into one dashboard, including services like parcel shipping; outsourced logistics services such as warehousing, fulfillment, transportation management, service parts logistics and returns management; quoting and booking for air and ocean freight; and the firm’s customs brokerage.

Alongside these services, the portal also includes access to the company’s supplier management solution, UPS Express Critical same-day delivery and next-flight out service, high-volume Mail Innovations service and the Coyote Logistics third-party logistics (3PL) business.

Eric Dolan, vice president, supply chain solutions data and innovation at UPS, told Sourcing Journal that Symphony was first available as a commercial add-on this summer, with “double-digit” customers using the platform.

Portal users have already tripled since the beginning of the year, Dolan said. Roughly one-third represent retail.

“Previously, you had to be a warehousing or outbound fulfillment customer to access Symphony. Now, we can offer this to parcel customers that experience heavy demand, and give them a mix of, for example, Coyote ground transportation and inbound air freight,” said Dolan. “More of our customers would say they needed something that would link these features together. “Otherwise, I’m going to procure you piece by piece, and I get no aggregate value by bringing it together.’”

According to Dolan, 90 percent of global volume in UPS’s supply chain is already logged within the portal for merchant users.

UPS debuted the technology to address the problem that many companies have when trying to cobble together separate spreadsheets or databases. Many shippers find it difficult and time-consuming to turn supply chain data into useful information.

Dolan says the pre-connectedness of systems within the UPS logistics network, like distributed order management, warehouse management and outbound fulfillment, make the Symphony offering tick. But he also highlighted the solution’s ability to integrate data from third-party carriers, giving users a more complete picture of the flow of goods.

“We have a lot of brokerage services that all work with third-party carriers, so you can turn that on right away,” Dolan said. “We also have APIs that we just introduced as another part of this push, that lets the customer say ‘Hey, I want you to connect to Maersk and bring a total picture to me,’ and we’ve set it up so that they can access transportation- or inventory-related information.”

As an example, Dolan said a well-known customer in the home goods vertical that is UPS’ largest Symphony client is ramping up its use ahead of Black Friday and the holiday season.

“They asked us to raise their number of users on Symphony tenfold and they were already our biggest client,” Dolan said.

Automated UPS Velocity warehouse features 700 robots

The UPS Velocity distribution facility in Shepherdsville, Ky. is expected to create up to 500 distribution and logistics jobs from 200 today.

The $79 million warehouse has more than 700 bots operating within, with plans to triple that number within the next year. The high-tech facility can process over 350,000 units per day—400 percent more than a non-automated warehouse.

Goods-to-person technology within the facility uses AI to arrange space for optimal speed and can even pick up inventory. And rack-to-person technology, developed by Geek+, increases storage optimization by 30 percent versus without, UPS said.

According to Dolan, the warehouse is part of UPS’ wider e-commerce distribution strategies, namely serving SMBs and midmarket customers.

UPS Velocity has staffed the facility with the help of the company’s Languages Across Logistics (LAL) program, which supports the recruiting, hiring, training, coaching, development, promotion and retention of refugees and immigrants.

The machine learning-powered technology understands more than 20 languages, enabling employees who speak different languages to work side by side.