Triple-Distilled Liquor Vs Continuously Distilled: Is There A Difference?

Roughly two out of every three Americans drink alcohol, but that ageless pastime wouldn't be the same without distillation. For the casual drinker, the process of making liquor may seem boring and complex but even having a vague understanding of what's happening behind the scenes can help you make sense of unfamiliar spirits. If you're trying to branch out from your habitual sipper, knowing what type of distillation you prefer can give you the confidence you need to venture into new territory.

Two common methods of distillation are triple distillation and continuous distillation. There are other methods than these, but these two are a good jumping-off point for the rest of them. Most liquors don't advertise their distillation method on the bottle unless it's a unique selling point, but if you have a specific brand of alcohol that you're curious about, it shouldn't be difficult to find out how it's distilled with a quick search online. Once you understand why a distiller might choose one method over the other, you might find that you're able to guess how a specific bottle was distilled on your own.

As a general overview, distillation works by heating whatever liquid is inside the still until it evaporates. The evaporated alcohol then gets cooled down to condense it back into a liquid, which will eventually become what goes into the bottle. How that process of evaporation and condensation gets done changes from method to method and there's plenty of room for innovation within these broader categories.

Read more: 13 Liquors Your Home Bar Should Have

What Is Triple Distillation?

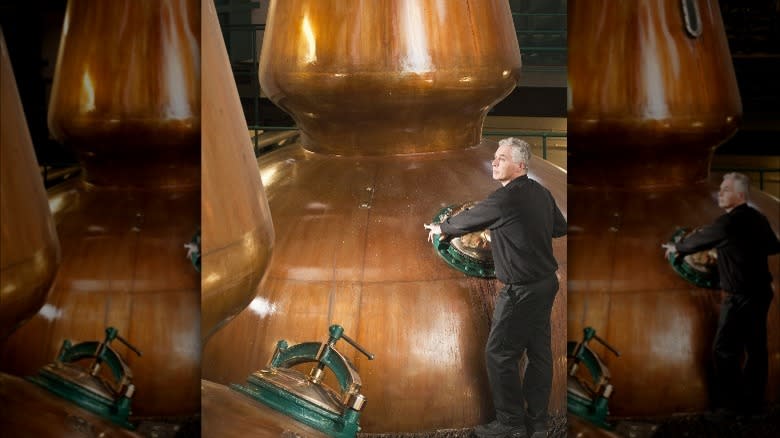

Triple distillation is one of the distillation methods that uses alembic pot stills. The process is essentially the same in all of the methods since they're using the same machinery, triple distillation simply means that they run it through a pot still three times before they call it good. We'll talk more about how the pot still works in a second.

Triple distillation can be found all over the world but it is especially associated with Irish whiskey. Irish distilleries prefer triple distillation for the impeccably smooth flavor it produces. Hard alcohol can be harsh and not everyone enjoys the bite behind the booze. Triple distillation softens the sharper edges of the drink, leaving a mellow and endlessly sippable whiskey behind.

Other spirits also use triple distillation. Whether it's triple-distilled gin, vodka, or tequila, the distillery is likely to tell you upfront that they've distilled the spirit three times because it produces a premium product and they're proud to be showcasing their work (and likely asking for a slightly higher price for that extra work as well).

What Is Continuous Distillation?

Continuous distillation is associated with the more modern column stills. It's called continuous distillation because that's exactly what it is, continuous. Pot stills must be thoroughly cleaned after each distillation which significantly increases the time it takes to run multiple batches through. Not so with column stills, which are built to channel a continuous feed of whatever is being distilled (known as the feedstock) through the still. We'll dive deeper into the mechanics in just a moment.

The real merit of continuous distillation is the sheer volume of alcohol that can be pumped out of these column stills. A moderately sized column still can produce hundreds of barrels of alcohol in a single day. This makes continuous distillation popular with bigger distilleries. Investing in a column still is likely not the first step for a small operation. But just because it can run for long periods of time doesn't mean you can just flip the "on" switch and walk away.

Continuous distillation requires professionals to monitor the data coming out of the machine and adjust the different variables involved if needed. Many distilleries will run a full three shifts to keep the still running 24 hours, though certainly not all of them go this route. Even if the still shuts down for parts of the day, though, it's still considered continuous distillation since the method of distillation is what matters, here.

The Two Distillation Methods Use Different Equipment

As we've touched on, the biggest difference between these two types of distillation comes down to the machinery used. Triple distillation uses alembic pot stills, whereas continuous distillation uses column stills (sometimes referred to as continuous stills). The interesting thing is that once you take a look under the hood, the difference between these two distillations becomes less and less clear.

You see, column stills can be thought of as several pot stills stacked on top of each other and housed in a larger column. The actual mechanics of column stills are incredibly complicated, but we can simplify it. First, the feedstock is released into the still where it's heated by steam. It then evaporates and climbs to the next higher section and continues to do that until it is released and condensed into the final distillate. In a way, this is very similar to how triple distillation works.

The similarity ends there, though, since column stills aren't actually pot stills stacked into a column. They're built with perforated plates at regular intervals which the distillate passes through, condensing the denser particles and leaving pure alcohol behind. This means that column stills are capable of producing alcohol that's as high as 190 proof, meaning it's 95% ethanol. Pot stills aren't capable of producing something that concentrated – not that this handicap closes very many doors.

Continuous Distillation Creates A Uniform Product

The thorough filtration that a column stills' perforated plates produce leads to a uniform end product that has few -- if any -- imperfections. That may sound unambiguously good, but, while we don't always appreciate our own imperfections, we definitely enjoy some imperfections in our alcohol. When we say "imperfections," we don't mean that the drink is somehow faulty. Imperfections are what give the spirit its unique flavor.

Triple distillation is considered smooth because it removes more imperfections compared to a single distillation spirit. A single distillation in a pot still can be perfectly delicious if done right, but it has a wild character. By distilling three times, a distiller can tame the beast so they're left with something refined and soft, almost fruity. But even triple distillation can't compare with the flawless distillate coming out of a well-oiled column still.

Remember how column stills are essentially constantly filtering out these imperfections by passing the vapors through the perforated plates? You can think of each of these plates as a mini-distillation. If the vapors pass over the plates 50 times, it's a bit like the spirit has been distilled 50 times. A professional distiller might take issue with this analogy, but it's a good way for a layperson to wrap their head around it. With that level of filtration, you can end up with something that tastes samey and mass-produced.

Pot Stills Are Associated With Smaller Craft Distilleries

This last difference is half true and half undeserved gossip but we'd be remiss if we didn't share it. Continuous distillation has a reputation for being synonymous with commercial products whereas triple distillation (and other methods that use pot stills) are more associated with the domain of craft alcohol. This is true on a couple of different levels, not the least of which is that big distilleries use continuous stills and smaller distilleries often use pot stills.

This is partly to do with the cost of each and partly to do with expected sales. If you're just starting out as a distillery and you're only expecting to sell a small amount of your product, it doesn't make sense to be pumping out hundreds of barrels a day. The fact that column stills are exceptionally talented at producing a highly filtered product also doesn't help its case. Part of what people are looking for in craft liquor is that wild, unique flavor that can be difficult to produce in a column still – though not impossible.

Some highly sought-after alcohols are made through continuous distillation -- Pappy Van Winkle bourbon being one such exceptional creature. If we're being honest, the fact that continuous distillation is more commonly used by big business distilleries and pot stills are more commonly used by smaller craft distilleries probably has more to do with this aspect of volume than it does with what each method of distillation is capable of.

Read the original article on Tasting Table.