How These Three Companies Attack Retail’s Returns Tsunami

Consumers returned nearly one-fifth of everything they bought online in 2022, resulting in $212 billion in potential losses to e-retailers. In the fashion sector, those rates often double, triple and in some spheres even quadruple, because, as as Optoro enterprise sales SVP Caroline Turner puts it, “The bedroom has become the dressing room,” and we’ve all been, “for better or worse, Amazon-ified.”

But modern technology and old fashioned customer service are rushing to solve this pain point to turn returns into returning business, and items stuck in warehouses back up for sale in short order.

More from Sourcing Journal

The psychology of the return

When returns happen, companies are motivated to leave customers feeling positively about the experience, and entice them to buy something before they leave.

“Ultimately, two-thirds of folks still want something,” Turner told Sourcing Journal. “So the more you can you can keep them on the site and pick something else out—that’s what it’s all about.”

Software like the end-to-end returns platform from reverse logistics technology provider Optoro is the bridge that allows that customer to be engaged without feeling inconvenienced.

“We’re doing these nudges to say, ‘OK, why are you returning it? Didn’t fit? How about pick a different size? We’ll ship it to you immediately. If you don’t want to buy a different size, hey, why don’t use a gift card? Why don’t you use it right now?” Turner said. Because acquiring a customer is up to four times more costly than keeping one, companies have every incentive to capture their dollars when the opportunity presents itself, she said.

She said that with Optoro, the new purchase can be shipped out before the undesired item goes back, and usually arrives in five days, during which time the return can be dropped off at any Staples or even picked up at their home.

In cases where customers prefer to take an “uneven exchange,” aka gift cards rather than exchanges, the nudging never stops.

“People spend about 20 percent more because, as we all know, the easiest way to use a gift card is to buy more of it—use more than the amount,” Turner said.

Optoro works with major retailers like American Eagle Outfitters and Gap Inc., as well as smaller e-commerce clothiers like Tuckernuck. Emily Grayson, vice president of operations at Tuckernuck, told Sourcing Journal her company saw a “98 percent return return-to-stock rate, with 78 percent of units resold within 30 days, and 99.9 percent of units diverted from landfills.”

Protecting against the serial-returner

Many customers who return items most are also the most profitable customers. But what can a business do to protect itself against the “serial returners,” those who return at least as much as they keep?

“I think you do want to avoid that person,” Lindsay Fisher, co-founder of UK-based Sparkbox.ai, told Sourcing Journal. “I think there’s really interesting things you could do if you can predict at the basket, whether or not a product will be returned and particularly whether it will be returned for that particular customer that’s shopping.”

Some businesses, Fisher said, will try to dissuade these shoppers by offering a discounted price if the sale is accepted as final. Those that identify problematic returners through software like Sparkbox.ai’s will stop offering those people promotions, or reduce the quality of photography on a piece of apparel on the website, perhaps resulting in fewer sales but improved profit.

Fisher said that her company, which focuses on predictive analytics to reduce waste in inventory, does not currently employ anything like a credit rating to predict a customer’s return risk, but implementing an algorithmic analysis wouldn’t be challenging technically.

“If you can right-size the amount of inventory you buy, you can have less to mark down and markdowns are really, really expensive for businesses,” Fisher said.

Tracking the returns

Practically any e-commerce sale can be tracked from the distribution hub to the last mile in real time. But when an item is returned its whereabouts and condition are often unknown.

How is a business supposed to plan for the resale value of a piece of merchandise when they don’t know when—or if—it can make it back to the shelves?

In most cases, the return goes to a third-party logistics (3PL) facility, that according to Two Boxes co-founder and CEO Kyle Bertin, usually deals with products according to “10-to-20 page PDF” instruction manuals, which can lead to “big, big bottlenecks.”

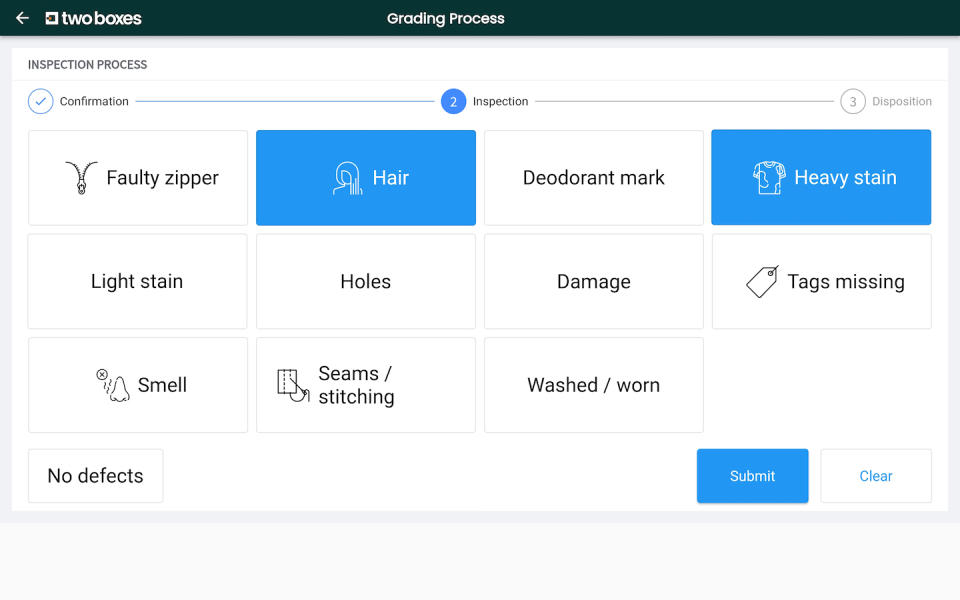

To solve the problem, Bertin and business partner Evan Stalter developed Two Boxes, a software that aims to use state-of-the-art technology to help humans perform the work related to returns.

With that technology, warehouse workers can skip the data entry and instead scan or touch icons on a screen to navigate the process to indicate what is wrong with the item.

“It’s a very simple and intuitive where the workflow is receiving the package, scan that package, pull up the details about the return, reconcile the inventory, and then it goes to unit-level inspection,” Bertin said.

He said current ROI is showing double-to-triple the efficiency for a 3PL on a per-hour basis. As for the brands, the software lets them know exactly where and in what reported condition the piece is in, which they can share with their customer, and it can let them know the quality of the returns and where the blame in the supply chain lies when a product isn’t in salable condition.

In the name of sustainability

Solving the returns mystery isn’t just a bottom-line challenge for fashion retailers; it’s one that could help keep apparel out of landfills.

“There’s a lot of inventory that ends up, you know, not being put to good use, and a lot of times it’s not because the inventory is in poor quality, it’s that the systems around returns are inefficient,” Bertin said. “That’s where we believe driving efficiency in the operations associated with returns we actually have an outsized impact on sustainability.”

Fisher said the biggest impact the fashion industry can have is to make supply match demand, and even Optoro’s “nudging” has its green purpose.

“Last year we diverted about 4.6 million pounds of goods from landfills,” Turner said. “We sent 32 million items to secondary channels… We try to find a home for every not-new item so it’s not going to a landfill.”