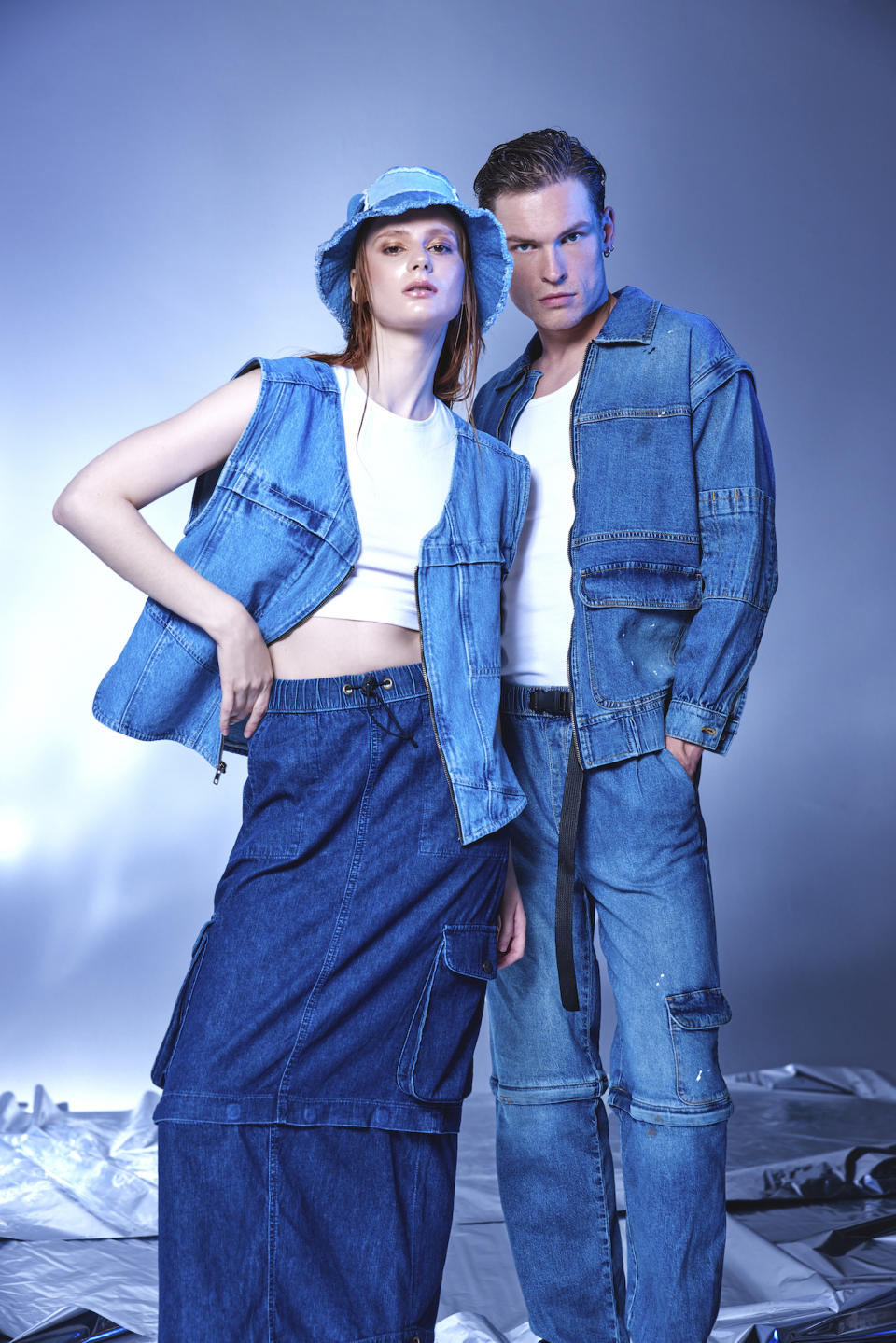

What’s Selling: Spring/Summer 2025 Denim Fabrics

What’s selling from mills’ Spring/Summer 2025 fabric collections is one way to find out what’s in store for the denim market.

Brands are sampling lightweight fabrics, chino-inspired constructions and unexpected colors. They’re also looking for versatile fabrics that can be applied to several designs. Here, representatives from mill’s share the fabrics getting the most attention for the season.

More from Sourcing Journal

What’s selling for Orta?

9TC30A, a lightweight 5.5 oz. chino 3 x 1 fabric with refined compact micro twill character, in the color Tsunami. The fabric is constructed with 100 percent Good Earth Cotton regeneratively grown in Australia.

“The chino has an oft disputed origin but many clothing historians agree that its likely adoption originates from 1850s U.S. and British military uniforms serving overseas,” said Sebla Onder, Orta marketing and sustainability manager. “This military staple became the de facto style of American university campuses across the U.S. in 1950s and became of the other corner stones of the Ivy League look and of the defining fabrics of American style, along with denim.”

Orta’s 9TC30A captures this aesthetic. It has a clean, luxury look with woven sheen, is soft and fluid yet durable—a key reason why chinos became a popular alternative to lined suit trousers, she added.

The fabric is suitable for contemporary soft tailoring silhouettes, smart casualwear and contemporary resort coordinates. “It’s fluidity and soft sheen are great for loose summer silhouettes,” Onder said.

What’s selling for Cone Denim?

Festival, a 13.75 oz. 3×1 right hand twill made with 100 percent cotton is Cone’s top seller for the season. It uses a retro inspired medium dip indigo, creating a unique surface texture with visual highs and lows at each wash level.

“We feel the overwhelming appeal for Festival is attributed to the yarn character and construction standing out in a sea of denim classified as authentic,” said Kevin Reardon, EVP of commercial strategy. “It uses a custom-designed yarn pattern that gives the appeal of worn-in vintage jeans. It is bold while feeling timeless. Festival captures the art of yarn design to create a beautiful pattern, resulting in standout vintage character.”

The fabric is produced in Cone’s plant where 90 percent of the water used is recycled back into the manufacturing process. Festival also has high Light Sensitive Fabric Test and Bluescan scores, making them a perfect fabric base for achieving a sustainable wash using laser technology, he added.

What’s selling for Crescent Bahuman?

XA-3997-B, a 9 oz. fabric made with 80 percent cotton and 20 percent post-industrial waste recycled cotton. Part of the mill’s Aerolite Collection, it is a lightweight, authentic-looking rigid fabric.

“Due to its softer hand feel and authentic character, this fabric has been the best pick for customers requiring the real authentic denim look and providing an overall comfortable experience,” said Imran Tanveer, Crescent Bahuman’s assistant VP of research and development.

The fabric is available in a wide variety of dark and light indigo colors as well as black.

What’s selling for Sapphire Mills?

The “Athena” fabric from the Blooming Horizons collection. The 2×1 twill fabric is comprised of 56 percent regenerative cotton, 37 percent Cordura, 3 percent Lycra and 4 percent Lycra T400. The performance-driven fabric is also enhanced with Stay Fresh technology, which ensures long-lasting freshness and adds a layer of hygiene to the garment.

“Athena delivers unparalleled comfort, longevity, and freshness with every wear,” said Deirdre Jennings, Sapphire Mills’ business development manager. “It distinguishes itself with a range of cutting-edge technologies from our strategic development partners Lycra and Cordura and others, each contributing to its popularity.”

What’s selling for Advance Denim?

Clients are responding positively to Advance Denim’s groundbreaking fabrics made textile waste, including the first denim that incorporates Grace’s Gracell fiber made with 50 percent Circulose from Renewcell. Produced using Circulose pulp made from 100 percent textile waste and FSC-certified sustainable and traceable wood sources, the Gracell product is dual certified by RCS and FSC.

“As with most trends these days, our best-selling items emerge as we present styles that live in the intersection between developing trends in Europe, Asia and the U.S., said Mark Ix, Advance Denim’s director of North American marketing. “As silhouettes got wider, and customers craved softness and drape we felt it was important to add circularity to this trend.”

Launched last October, the innovated fabric offers higher strength compared to conventional bio-based short fibers, has good shape retention and a soft touch. It is available in two compositions. QA268V8-3A contains 40 percent cotton, 32 percent Gracell Circulose, 14 percent recycled polyester and 13 percent recycled cotton. QA268V8-3A contains 30 percent Gracell Circulose, 15 percent recycled polyester, 12 percent recycled cotton, 18 percent Carbon Zero Tencel, 23 percent cotton and 2 percent spandex.

What’s selling for Naveena Denim Mills – Karachi?

ZINT, a 11.75 oz. 3×1 twill made with 99 percent cotton and 1 percent elastane. The fabric is unique for its 30-35 percent elasticity and marble aesthetic.

“ZINT fabrics address one of the latest trends in the market which is authentic and rigid look. However, on top of the marble look they provide, they also offer high elasticity. This character is very difficult to achieve in high stretch levels, as traditionally, when stretch level is increased, fabrics becomes flatter and more compact. Marble character is reduced with high stretch,” said Aydan Tuzun, Naveena Denim Mills executive director of sales and marketing.

The fabric is a part of Naveena’s popular Retrotech collection of vintage-inspired fabrics that offer comfort and a soft hand. It is available in over 15 colors.

What’s selling for Soorty?

Cobain Blue GRS, a 10.75 oz. 3×1 right hand twill made with 79 percent BCI, 20 percent post-consumer recycled cotton and 1 percent elastane.

Known for its authentic character and vibrant blue color, the medium-weight denim offers a soft and comfy feel, along with a comfortable stretch. Noman Nadir Khan, Soorty’s VP research and product development – denim, said the fabric “represents a blend of quality and substance” and underscores Soorty’s dedication to environmentally conscious practices and ingredients.

Other popular fabrics are the Santner Pulse Blue GRS, which has a distinctive slub texture, and the Roden Mars Blue, a high-stretch fabric with dyed with sustainable indigo technology.

What’s selling for US Denim?

Vintage Ease, a collection of 3×1 weave fabrics and chambrays spanning 4.75 oz. to 12 oz. The collection includes blends of cotton, Tencel, linen and elastane, resulting in easy and relaxed constructions that can be applied to a variety of garments, said Intizar Ali, US Denim’s general manager research and business development.

The collection uses the mill’s Eco-Advance dyeing process that requires up to 90 percent less water, 30 percent less energy and 10 percent less indigo compared to traditional dyeing methods. The fabrics are also laser friendly.

What’s selling for Tat Fung?

On the Go, a collection of fabrics designed for a sportier lifestyle. The fabrics consists of a blend of cotton, recycled polyester and Lycra. “The elongation of the fabric is meticulously designed to suit daily wear,” said Tim Huesemann, Tat Fung’s sales director.

“This fabric is lightweight and incorporates recycled polyester, resulting in a natural quick-dry function,” he said. “The combination of its light weight and comfort stretch engineering makes these jeans the ideal on-the-go pants for anyone.”

What’s selling for Global Denim?

One of Global Denim’s best-selling fabric groups is Yokohama, a 10 oz. 3×1 right hand twill with a soft handle and a touch of drape. The “Agean Blue” fabric is made with 99 percent cotton and 1 percent Lycra.

Yokohama is “perfect for the 2000s-inspired look that is gaining momentum among the trends and Gen Z [consumers],” according to Anatt Finkler, Global Denim’s creative director.

Due to its high performance and interest, Global made the fabric into a group and added a PFD version. The mill is testing different colors achieved through foam dying. “Now we are offering Dune and Olive, and what’s beautiful about them is that they can wash down just like indigo,” Finkler added.

What’s selling for Calik Denim?

RE/J and Selfsized are two of Calik Denim’s top products. The mill promotes circularity with RE/J, a range of fabrics made with 100 percent pre- and post-consumer recycled content. Additionally, the circular fabrics are dyed with Calik’s Dyepro technique, a water-free method with no chemical waste.

With Selfsized, Calik provides a technology that helps reduce the number of jean sizes brands must make and minimizing the risk of purchasing the wrong size jeans in online shopping.

What’s selling for AGI Denim?

Legend, a medium weight 3×1 right hand twill with high stretch and a comfortable drape. The fabric contains 81 percent cotton, 10 percent post-industrial waste cotton, 8 percent polyester and 1 percent elastane.

“This genderless denim features mid-dark indigo dye and slightly higher stretch than what the market calls comfort stretch,” said Ali Tekin, AGI Denim’s research and development director.

The fabric is available in different shades from dark to light indigo. Several of AGI Denim’s innovations can be applied to Legend, including Kaleido, a color yarn dye technology that uses recycled water, and its color weft concept called Weft Games.

“The widespread success of Legend across various markets and among customers can be attributed to its distinctive finishing traits, including a specialized blend of shade deposits and unique warp characteristics,” Tekin said. “The fabric and yarn structure of Legend is designed to develop an appealing chip-off character through various washes. We’ve modernized the classic homespun texture, adding an extra layer of depth to the fabric’s surface. This innovation offers a contemporary aesthetic while still maintaining the classic appeal of traditional denim.”

What’s selling for Vicunha?

Letizia REGEN, a 10 oz. 3×1 fabric made with 98 percent cotton—a blend of BCI and regenerative—and 1 percent elastane. It has a subtle slub character suitable for multiple styles.

One of Vicunha’s best-selling fabrics for several years, according to Kürsad Cakilcioglu, product development and sales manager for Vicunha in Europe, the fabric is now being developed with Brazilian regenerative cotton. The fabric supports the mill’s goal to promote local sustainable production of denim through regenerative practices, Cakilcioglu said.

The fabric, which is a bright and pure indigo shade, carries the Regenagri certification which ensures the chain of custody traceability of regenerative cotton.