This Quaint English Village Has the World's Original Cheddar Cheese Caves

Funky Stock - Paul Williams / Alamy Stock Photo

When you travel to South West England, you'll often hear about Bristol and Bath, both dining destinations in their own right, but the home of cheddar is worthy of a day- or weekend-trip itinerary if you have access to a car (or a tour bus from London, if you'd like to pair hiking or climbing with your walk through the famous cheese caves).

The village of Cheddar is an easily overlooked pit stop with picturesque gorges, historic caves, and the one and only Cheddar Gorge Cheese Company, a storefront with samples, provisions, and gifts from the production and aging facility on site. Purchase modestly priced tickets inside for a self-guided tour through the back door where you can see what makes cheddar, cheddar.

Stroll through photos and artifacts exhibiting the cheese's rich history, from dairy farming to royal wedding gifts, with windows into the production and packaging happenings along the way. TVs loop video of the steps that go into the process of making cheddar where it originated.

RELATED: There's a Cheese Trail in New York's Finger Lakes, and It's Glorious

For cheese fans who've already seen cheesemaking demonstrations at destinations on the beaten path, like Beecher's in Seattle (and New York) or Murray's in New York, ask to see the schedule in advance. There are set times for viewing each technique live, and this may be your only chance to see the main event: cheddaring.

To time it right, factor in a tour of Gough's Caves across the street, a short walk away. It's worth another ticket price and comes with an audio tour (in multiple languages) detailing a rich history beyond aging award-winning cheddar — in fact, the oldest complete skeleton in England was unearthed here, and you'll see the stalagmites and stalactites of long-forgotten science classes come to life.

Ashley Day

The formations are other-worldly and mesmerizing, though the damp chill will keep you moving. It's the temperature and humidity that have made this maturation method so convenient for centuries, but we'll get to aging.

How Is Cheese Made?

Cheesemaking starts with gradually heating milk in a vat to shock cultures to life so they can ripen. The Cheddar Gorge Cheese company uses local, unpasteurized milk to harness its natural elements and impart the terroir from cows that graze in Somerset; a mixture of mesophilic and thermophilic starter cultures that grow at the optimum temperatures for cheddar; and a microbial rennet rather than animal-based to accommodate vegetarians and foster sustainability.

Luke Shepherd, a baker who studied cheesemaking at The School of Artisan Food in Nottinghamshire, has been one of the three cheesemakers working on a rotary system here for five years. He walked me through these distinctions and his day to day in the dairy on a recent call after my visit.

Rob Rothwell / Stockimo / Alamy Stock Photo

Next, rennet coagulates, solidifies, and ultimately makes the milk gelatinous as it transforms to curd. The milk's cut three times: "The smaller the curd is, the better," Shepherd explained. This minimizes moisture when the curd is pressed in a cheese mold, after it's been carefully scalded and steamed at five- and 10-minute intervals to maintain the desired temperature.

"There's an hour when the curd needs to just rest and be mixed and stay at a constant temperature of 41°C [106°F]," Shepherd continued. "When we come back, we drain the whey off and then shovel the curd onto a cooling table — and that's when the cheddaring process begins."

This entails cutting blocks of curd, stacking, and flipping while monitoring acidity. "Basically we flip them and turn them and test the acidity," said Luke. "We do a TA (Titratable Acidity) test every time we cut the curd. It'll tell us how fast the acidity is moving within the curd."

When the fresh whey is too acidic, they let the curd rest for 10 minutes before proceeding. "If you rush it, it's going to break apart and that's what you don't want in the cheddaring process. You want it all to be staying together."

Patience and precision are pivotal for the desired texture.

RELATED: How to Talk About Cheese Like You Know What You're Talking About

"It sounds weird, but it's like if you pull chicken breast apart with your fingers; that's the sort of texture that you're looking for in your blocks of cheddar," Shepherd explained. "If it hasn't reached that and it's quite crumbly, you're not quite there yet. You have to keep flipping it and waiting for the acidity to get to the right measurement."

That manual labor is just beginning. "Once it's ready, we basically cut those stacks of three into strips. We line it up at the top of the cooling table, throw a layer of salt on, and then we'll put the curds through the mill individually," Shepherd described. This churns out "tiny bits of cheddar. We mix in more salt with our hands because we don't use any machinery at our dairy. It's all by hand so there's a lot of arm work that goes into mixing six kilos of salt into a lot of curd."

Finally, the curds are pressed in cheese molds overnight. Some will be aged for six months, grated, and sent to a local bakery, and the rest remains for three days before being cloth-bound and matured. There's scalding to form a rind, more pressing to remove moisture, and then an edible PVA glue called Plasticoat is used in place of butter or lard. Suitable for vegetarians, the "pasta coat" also protects the cheese from mites.

"It's basically an organism that loves to eat fat, butter, and dairy products," Luke explained. "If you cut into traditionally clothbound cheese, nine times out of 10 it will have a brown spot in it. It's like a fine dust that comes out of a cheese, and if you put it under a microscope, you'd see the organisms moving around. The more cheese mites you have, the more wastage."

Plastic coating and non-animal rennet are the dairy's exceptions when it comes to traditional cheesemaking, but its aging is about as traditional as it gets.

The Original Cheddar Cheese Caves

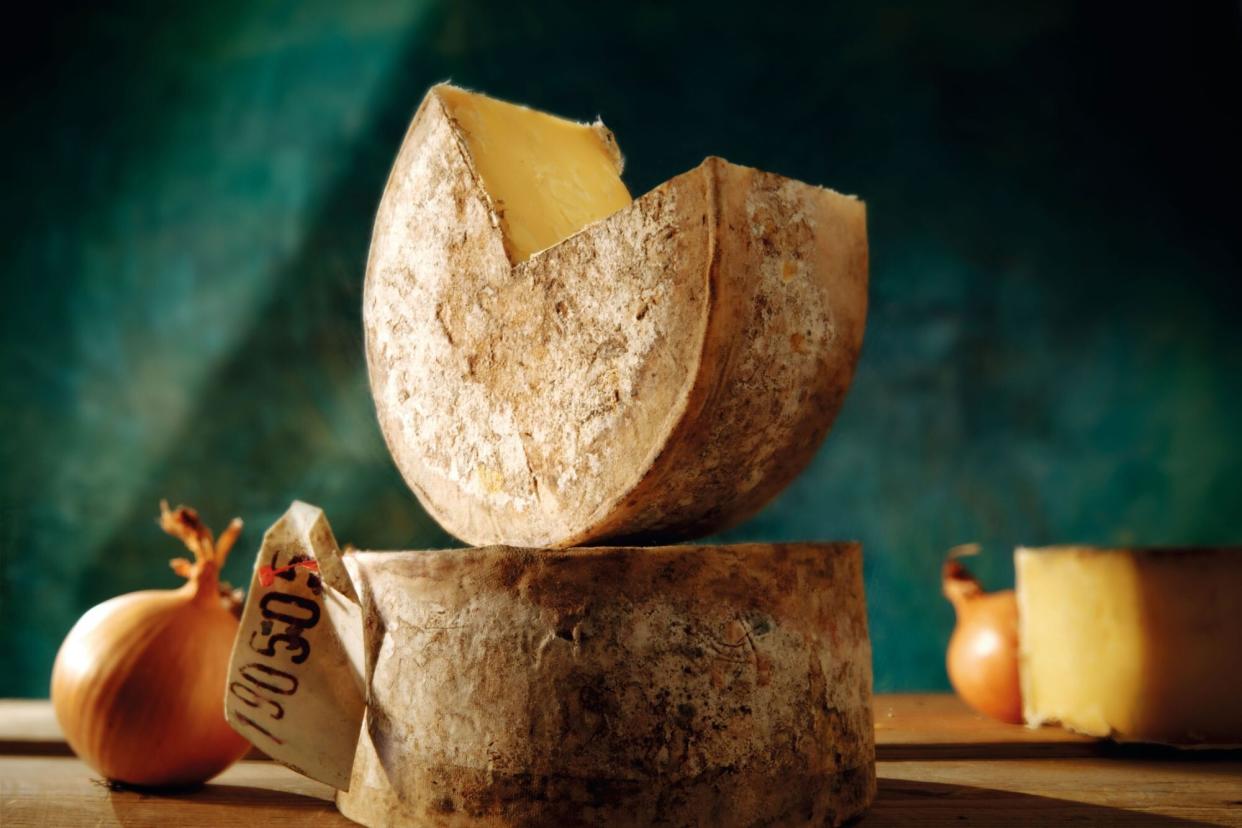

Cheddar Gorge Cheese Company ages many of its cheeses in three store rooms: six months for mellow, 15 months for extra mature, and up to 30 months for vintage (all award-winning between 2019 and 2021). But you visit to try the cheddar that matured in caves for a year.

"The caves are a natural store system. All cheesemakers try to emulate what the cave does," Shepherd said of the storage method that began long before refrigeration. These caves were formed 500,000 years ago, with the first mention of the cheese here dating to 1170, when King Henry II purchased more than 10,000 pounds.The type was officially named cheddar in 1500.

Ashley Day

While the popular cheese has changed a lot since then, from access limited to royalty in 1625 to the confinement of "government cheddar" during World War II, the caves are constant. The environment maintains 100% humidity and a temperature of 11°C (52°F) all year round. Industrialization eliminated traditional cheese maturation for a time, but in 2006, the lone Cheddar Gorge Cheese Company returned to these roots.

"We store our cheese in the middle of the cave system — it's prime location, really," Shepherd explained. "It's not too close to the floor; it's near the roof of the caves so there's not going to be any water damage if the caves flood. It is an underground riverbed so the caves do flood, but it doesn't change the humidity in there. It allows the cultures within the body of the cheese to move more quickly. One or two degrees and the humidity can make a massive difference to the texture and the quality of the cheese."

Joe Daniel Price / Getty Images

The longer it's matured, the sharper the cheese, meaning the flavor's more concentrated. Plus, as more moisture is eliminated over time, the cheese becomes drier and more crumbly.

"Cheddar is quite unique because of the fact that you can make a cheddar the same as a mellow or a vintage, but they're going to taste completely different. Some people like earthy taste, more people like tangy taste. Not all cheeses can have that range of flavor," said Shepherd.

RELATED: 10 Recipes for Cheddar Cheese Lovers

You can taste about 10 flavors in the cheese shop, from oak-smoked to cheddar with chili flakes, alongside a bounty of accompaniments for a picnic, hike, or road trip.

Steps away, Jacob's Ladder offers some 274 steps to cliff views above, with stops along the way and a natural trail through the Cheddar Woods. This is a small, somewhat touristy village with shops and seasonal crowds, but there's plenty of outdoors appeal and opportunities to get active after tasting your first cave-aged cheddar from Cheddar.