Photonic Labeling Stokes Demand in Fashion

Could butterfly wings be the inspiration that unlocks textile waste sorting, authentication of designer handbags and easy adherence to new labeling laws?

Similar in theory to the way butterfly wings are coded to reflect light, the science of photonic labeling represents a viable textile use application and one in which researchers at the University of Michigan are working to solve, patent and scale. In an email interview, WWD caught up with University of Michigan professor Max Shtein and postdoctoral researcher Brian lezzi, in the materials science and engineering department, on their findings and why fashion should pay attention.

More from WWD

WWD: How would you describe your work?

Brian lezzi: I have been active in the sustainable materials community for several years and one “waste” stream that typically gets overlooked is textiles. Beyond donating to secondhand stores, most people throw away their used garments, with around 85 percent ending up in landfills in the United States.

It is important to mention that most donations end up being shipped to Asia, South America or Africa to be either resold or disposed of there, greatly increasing the end-of-life carbon footprint and depressing local textile manufacturers. But with rising material costs, and the associated benefits of potentially reusing fibers in new products, there has been an increased focus on methods that can be utilized to recycle textiles domestically.

Sorting the clothing into streams with similar material composition (i.e. polyester, cotton, wool) is critical to the recycling system, since the processes that follow are different depending on the composition of the textiles, whether mono-material or blended fibers are used, which are increasingly common. A 2017 Ellen MacArthur Foundation report indicated that capturing the value of used textiles could be a $500 billion-a-year industry. Our work is focused on making sorting and subsequent reuse, repair or recycling of textiles more efficient to realize a circular economy.

WWD: What is photonic labeling? How does it work? Has this science ever been utilized before in fashion?

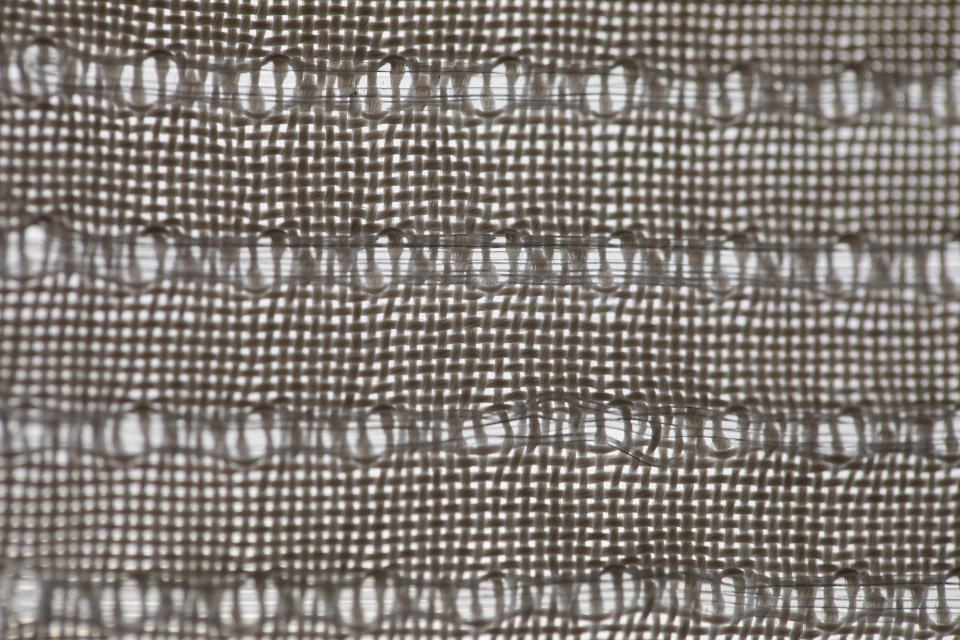

Max Shtein: Photonic labeling is a way to utilize how materials interact with light as a method of adding a unique identifier to an object. We have developed a fiber [that] has a material structure within that can control certain types of light (butterflies have similar structures in their wings to create color). We can control this material structure to create unique light signatures that can be read like how a barcode is read in the store.

The exciting part of the invention is that the fiber is a similar size to traditional textile yarns, such as polyester and cotton, and can be woven, knitted or sewn into fabrics so it cannot be removed, becoming a permanent identifier for the textile. The technology to create these fibers has actually been around for about two decades, and has been proposed as a method of identifying friendly units in the military. But this is the first, to our knowledge, application and use as a commercial labeling system.

WWD: What benefits does photonic labeling have across the fashion supply chain? Can this already integrate into existing systems, such as textile recycling? Why or why not?

B.L.: An exciting aspect to this technology is that it can have positive impacts across several supply chain sectors. For example, direct weaving or knitting of the fibers into textiles provides an upstream identifier that can be used for supply chain traceability. Furthermore, the unique signatures that can be created also provide another method of product authentication to brands working to prevent counterfeiting.

Finally, since the label is integrated directly into the fabric, it is not easy to remove, which is a current down-side to current labels (a recent study from Circle Economy found 29 percent of labels were not there or legible at the textile end of life), thus providing a more robust method of determining fiber composition for recycling at the end of life. The fibers are potentially compatible with existing high speed, automated optical sorting systems (such as the SipTex project in Sweden) and, since they are made of commodity polymers, could be compatible with existing chemical recycling technologies that break down fibers to their constituent molecules for creation of new textile fibers and yarns.

WWD: Can or should an entire garment be made with photonic fibers? What would it cost?

M.S.: There was an effort in the early 2000s to utilize photonic fibers to provide color to textiles. Instead of using dyes, the fibers had tuned photonic properties to make blue, green and red. The project resulted in the creation of a prototype dress called Morphotex, after the morpho butterfly. So technically, yes an entire garment can be made with photonic fibers. However, the project never took off the ground on a commercial scale. We don’t know the specifics of why, but it might be because the fibers are not quite at cost parity [with] traditional textile yarns and thus making entire garments out of the fibers on a commercial scale might not be feasible.

That being said, the fibers are made with relatively low-cost commodity polymers that are in wide circulation and can be made with large-scale manufacturing techniques, similar to how current synthetic textiles fibers are made. In comparison, the photonic labeling system could be a very low percentage (potentially as little as 1 percent) of the overall garment while still being readable, so this makes it more economically viable as a labeling system. We currently estimate the amount needed to integrate to “label” a garment would add around $0.25 to the price of a garment, similar to the cost of use-and-care tags currently in use.

WWD: What information should be communicated on a photonic fiber tag amid new regulation, like in the European Union?

B.L.: This is a great question and one we are in active communication with regulators on, both in Europe and the United States. In Europe, the requirements to have a Digital Product Passport (DPP) that provides not only easily accessible value chain information, such as what a product is made of, where it was made, and the associated environmental and social impacts, but also what is required for disposal at the end-of-life to promote circularity.

Similarly in the United States, lawmakers in California are currently proposing SB 707, or the Responsible Textile Recovery Act, to require Extended Producer Responsibilities (EPRs) for fashion manufacturers to set up collection sites for reuse or recycling. Sorting the textiles from these collection centers in an economical way is going to be critical to properly recycling them and a photonic fiber tag could help enable more efficient, large scale sorting. [American Society for Testing and Materials] is currently working on their E60 committee which is aimed at creating standardization around textile labeling for circularity which should set standards for what new information, in addition to existing care instructions and fiber composition, is required on the label.

WWD: How far along is this innovation, and what amount of funding is needed to scale the technology?

M.S.: This is a new invention and, based on what is needed in the industry, there will likely need to be further technical development to meet needs. However, the process for creating our fiber is very scalable; in the laboratory we can create kilometers of the photonic fiber barcode in a very short time frame. The materials used in the fibers are also very low cost, being commodity plastics that are easily available worldwide. Because of the scalable manufacturing method and the low material cost for the fibers, we think that this photonic barcode could be ready for commercial integration on a large scale in a short time frame, potentially within a few years, and on a small scale much sooner.

It is hard to estimate how much funding is needed to scale the technology but, with input from the needs in industry, we estimate that creating a viable product should be possible with minimal follow-on funding. That being said, the infrastructure needed to support the technology, such as automated sorting equipment, will require more investment on the part of municipalities, regional and national governments as well as support from industry dealing with EPR requirements.

WWD: Anything else to add?

B.L.: We have applied for patent protection and are actively pursuing commercial applications for the technology. We are interested in speaking to representatives from the fashion industry who would be interested in partnering to help bring the labeling system to market in a useful, sustainable and swift manner.

Best of WWD