P448’s Invasive Species Sneakers; Zara Launches New Loopamid Tech Jacket: Sustainable Short Takes

SNAKES ON A TRAINER: Italian streetwear brand P448 is launching a new sneaker made out of Burmese python as part of its efforts to use alternative leathers and educate consumers about invasive species.

It’s the third in a series from the Mark Wahlberg-backed brand’s line of shoes made from invasive species, following lionfish and carp.

More from WWD

Fashion Executives Plan to Eliminate Plastic Packaging: Aquapak Survey

Planet Tracker Accuses Apparel Sector of Ignoring Water Risks

Fashion for Good Museum Unveils Its Final Exhibition, Plans Expanded Coworking Space

The skins are sourced from Florida, where the snakes, which are native to Southeast Asia, have become an invasive species after people released pets into the wild. They have devastated the native species of Everglades National Park, reducing populations of bobcats by 87.5 percent, for example, and effectively wiping out rabbits and foxes in the ecosystem.

“A big part of sustainability is creating value from new materials, thus rethinking what we know as luxury — bombarding the consumer with facts and figures isn’t as effective as education,” said Wayne Kulkin, founder and executive chairman of parent company StreetTrend.

The company has looked for sustainability solutions outside of the traditional leathers as part of the brand’s “Regenerative Sustainability” initiative to make 30 percent of its products from more sustainable materials.

The brand then tests the skins at tanneries to ensure they are usable and durable for footwear.

“P448 has a deep interest in sustainability and challenges itself to look at sustainability in a different way by putting in the work, time and money to source new ideas to achieve the best future environmental results. In doing so, it is blazing a trail as a pioneer in the field,” said chief product and sustainability officer Sabrina Cohen.

The Burmese python sneaker trim is detailed with repurposed natural black and white python skin from the invasive species within the front tip, tongue and heel. Other sustainable specs are Evolo-certified velour and almost everything else from recycled sources including outsoles, lining, organic cotton laces and brass eyelets.

The company will launch a film in conjunction with the shoes following environmentalists and removal contractors through the wilderness tasked with removing these species from the ecosystem. Their most recent film about the lionfish was featured in the London Fashion Film Festival last September.

The limited-edition sneakers will retail for $595.

IN THE LOOP: Zara launched its first jacket made from Loopamid, the first polyamide, aka nylon, textile made from 100 percent textile waste.

Everything in the jacket is made with Loopamid, including the buttons, filling, hook, loop and zipper.

The material was jointly developed by Zara parent company Inditex and chemical producer BASF, which unveiled the development of the textile simultaneously.

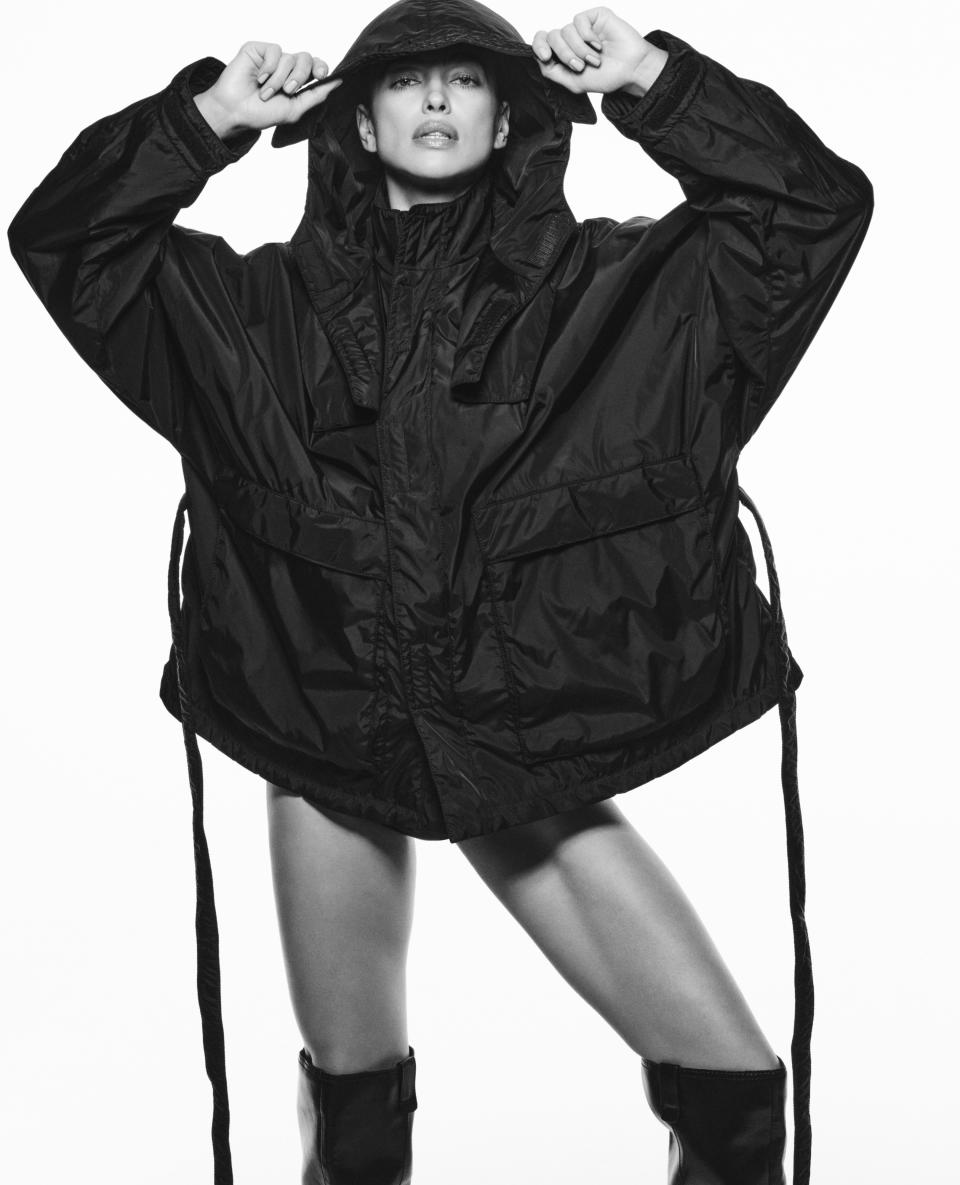

Zara launched Loopamid with a splashy campaign featuring Irina Shayk.

Loopamid was designed to be recycled repeatedly, with the material keeping the same characteristics as virgin polyamide.

“BASF has reached an important milestone toward circularity in the fashion industry and pioneered an approach to close the loop for nylon textiles,” said BASF monomers division president Dr. Ramkumar Dhruva.

BASF is working to scale up the technology to make it more widely available in the market at commercial quantities to other brands and suppliers.

“The capsule jacket together with Inditex is the proof that circularity is possible, and we are eager to further drive the sustainable transformation of the textile industry,” he added.

The project used feedstock from the Spain’s textile take-back program, and also a slew of supply chain partners from Italy to Japan to make the jacket happen.

Javier Losada, Inditex’s chief sustainability officer, added, “Driving innovation is key to advancing toward a more responsible industry. This collaboration is a great example of how, by collaborating all together, we can use the new technology to transform textile waste into a new resource.

“This project is also a first step to move towards a circular solution, as the industry still needs to boost new collecting and recycling capacities in order to close the loop and scale recycling for post-consumer waste,” Losada said.

Inditex’s sustainability goals aim to have 25 percent of their textile fibers made from next-gen materials by 2030, even as the group admits the materials “do not yet exist at an industrial scale.” The company has been investing in R&D on new materials in an effort to meet this target.

WARM UP STRETCH: Chemical company Celanese Corp. and Under Armour have developed a new fiber, Neolast, for performance stretch fabrics that has the potential to be recycled.

While there have been some recent breakthroughs on how to separate and recycle elastane, better known as Spandex, using solvents, it’s a major problem for the apparel industry that has yet to be solved.

“This new Neolast fiber represents a transformative innovation for Under Armour and the textile industry, embodying our commitment to building better products for our consumers and planet,” said Under Armour senior vice president of innovation Kyle Blakely.

“Through performance-driven sustainability and innovation, we look forward to helping athletes play at the top of their game as we work with Celanese to realize this new fiber’s potential to forge a path toward circularity,” he said.

The new Neolast fiber will be produced using a recyclable polymer, which could be a first step toward a solution for blended textiles and garments, such as stretch jeans. The companies will continue to research recycling systems for the new fiber.

It could help solve one of the biggest challenges for the sportswear industry. They plan to make the fiber available to the broader apparel industry in hopes that it can reduce elastane dependence. Under Armour and Celanese are working toward global commercialization in the near future, and the brand will have more to announce on its plans for this fiber in the coming months.

Best of WWD