Material World: Running on Coffee

Material World is a weekly roundup of innovations and ideas within the materials sector, covering news from emerging biomaterials and alternative leathers to sustainable substitutes and future-proof fibers.

Khalifa University

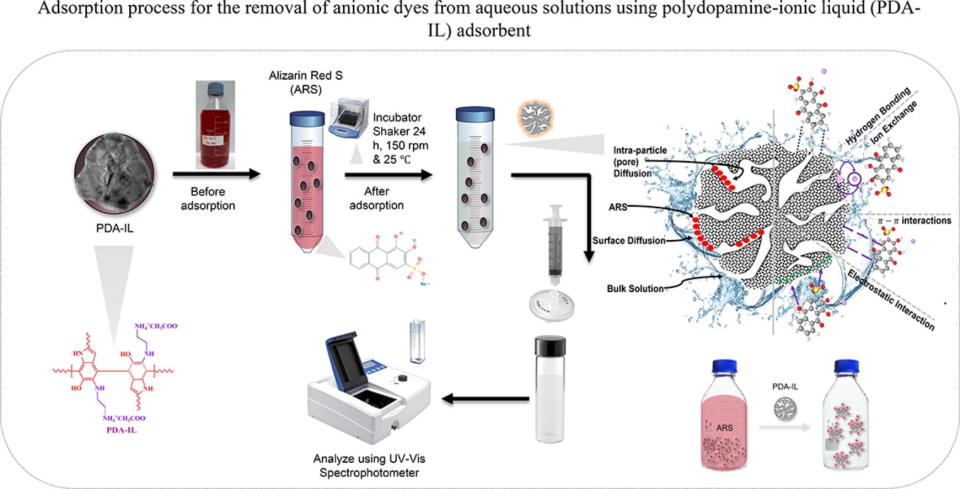

Mussel-inspired nanomaterials take inspiration from the adhesive properties of mussels, which are known for their ability to attach themselves to various surfaces. Scientists at Abu Dhabi’s Khalifa University have attempted to replicate this ability in their selective nano-adsorbent material, which extracts toxic dyes from wastewater.

More from Sourcing Journal

“The textile industry is one of the largest contributors to dye wastewater pollution,” Dr. Enas Nashef, professor of chemical engineering at Khalifa University, told Sourcing Journal. “We have developed this nanomaterial which demonstrates high adsorption capacity and strong affinity toward various types of dyes based on their charge, and can be employed as an effective absorbent to remove dyes from textile wastewater. Integrating this technology into the wastewater treatment process can help reduce the industry’s environmental impact and ensure compliance with regulatory standards.”

This innovation is scalable, too. Since polydopamine functionalized ionic liquid materials combine the adhesive properties of polydopamine and the tunability of ionic liquids, this material can be used in various applications such as coatings, catalysis, biosensing, energy storage, sensing and more.

“The key component of mussel-inspired nanomaterials is their unique functional groups that can selectively bind different pollutants based on their charge,” Nashef said. “On the other hand, since the material is synthesized from polymerized dopamine, it can be less toxic, and functionalizing it with green solvents as the ionic liquid can create a material with higher surface area, modified functional groups and better stability. This research was inspired by the unique characteristics and properties of both polydopamine and green solvent [ie, ionic liquid], which aimed to be utilized in the creation of functional nanomaterial for wastewater application.”

Plus, the nano polydopamine-ionic liquid (NPDA-IL) can be regenerated and reused, which is helpful for dye-related wastewater treatment, Nashef said.

“We have utilized this absorbent over four cycles with limited deterioration in absorption capacity,” he said. “While the absorbent reaches its saturation point, it can be regenerated, allowing for multiple cycles of dye absorption. This reduces the need for frequent replacement of absorbents and contributes to cost savings.”

The research team of professor Hassan Arafat, Rawan Abu Alwan, Botagoz Zhuman, Dr. Mahendra Kumar and Nashef was supported by the Center for Membranes and Advanced Water Technology (CMAT) at Khalifa University, which looks for sustainable solutions to the UAE’s water scarcity challenges.

Dahsheng Chemical (DSC)

The latest sustainable innovation from Dahsheng Chemical (DSC) turns some of the spent grounds from the 2.25 billion cups of coffee the world consumes daily into its new Dreamcell Xpresso insole foam technology with odor- and moisture-controlling features.

“DSC is committed to reducing our impact on the environment by using innovative biomaterials to reduce waste and fossil fuel usage,” Johnson Chang, CEO of Dahsheng Chemical, said. “With Dreamcell Xpresso, we can extend the life cycle and support a circular economy that benefits both manufacturers and consumers without compromising on comfort and performance.”

Used coffee grounds sent to landfill produce methane, causing a greenhouse effect 28 times higher than carbon dioxide. DSC works with local coffee providers in Vietnam—the world’s second-largest coffee producer—whose average annual coffee ground waste totals 180,000 tons. Dreamcell Xpresso tackles greenhouse gas emissions by rerouting those grounds from a landfill fate to a footwear component.

The Dreamcell Xpresso polyurethane (PU) open-cell foam is made with 20 percent coffee ground waste, decreasing the amount of fossil fuels and energy in the production process. For every one million pairs of Dreamcell Xpresso insoles produced, DSC will recycle approximately 2.19 metric tons of spent coffee grounds, which amounts to a 0.53 metric ton reduction in landfill methane emissions. That’s the equivalent of carbon sequestered by 219 tree seedlings grown for 10 years.

Insempra, Fibers365

Biology-powered company Insempra and Fibers365, which offers chemical-free processed fibers and substrates from annual plants, are working to develop and scale sustainable second-generation (2G) feedstock for the commercial production of fermentation-based ingredients, which could someday have applications for the textile industry.

2G feedstocks—also known as lignocellulosic feedstocks—can potentially reduce greenhouse gas emissions by replacing fossil-based and deforestation-based ingredients and consumer products by utilizing agricultural residues. Fibers365’s patented, modular, farm-level Steam Fiber Plants allow the competitive extraction of functional cellulosic fibers, lignin and sugars from multi-feedstock non-wood biomass. The sugars, which are currently used for the generation of biogas, can produce high-value products via fermentation.

But one of the challenges with 2G feedstocks is the intrinsic material stability of lignocellulosic materials. Unlike first-generation feedstocks derived from beets, corn and sugarcane, which contain easily accessible sugars, lignocellulosic biomass is composed of complex structures that require pre-treatment and enzymatic hydrolysis to release the sugars. Thus, developing efficient and cost-effective pre-treatment methods and resilient enzymatic cocktails for biomass construction is a challenge in adopting 2G feedstocks at scale.

“By working together with Insempra, we are combining our unique 2G feedstock derived from agricultural side streams with the highly advanced fermentation technology platform needed to scale and make this sustainable feedstock accessible to broader applications,” Stefan Radlmayr, founder and managing partner of Fibers365, said.

Insempra has tested Fibers365’s 2G feedstock derived from agricultural waste streams (wheat straw) with its proprietary fermentation technology platform. Insempra is using this technology to develop specialty lipids for application in the beauty and personal care industries as well as nutraceuticals and food industries. Insempra is also working on producing protein fibers and high-value functional ingredients with 2G feedstocks from agricultural waste.

“Using second-generation feedstocks in our manufacturing processes has always been one of our priorities as a biology-powered business,” Jens Klein, CEO and founder and Insempra, said. “We are tremendously excited about the potential this technology not only have for our businesses, but for the whole industry.”