Material World: Harnessing Plant Power

Material World is a weekly roundup of innovations and ideas within the materials sector, covering news from emerging biomaterials and alternative leathers to sustainable substitutes and future-proof fibers.

Unless Collective

Unless Collective was born to die. The regenerative fashion company that makes 100 percent plant-and-mineral-based clothing and footwear strives to be a regenerative force for good, creating the first brand whose products leave zero waste product at the end of life.

More from Sourcing Journal

“We were inspired by the opportunity to build a plastic-free future for fashion by creating the world’s first regenerative brand with a completely plant-and-mineral-based supply chain,” Tara Moss, co-founder and CMO of Unless, said. “Everything Unless made is designed to harmlessly return to the elements at the end of its long, useful life. We set out to create and operate the world’s first regenerative fashion platform—connecting material, design, manufacturing and composting to use plant-based innovation and production ingenuity to solve for a plastic-free future.”

The Pacific Northwest-based company cofounded by Eric Liedtke, former global brand president of Adidas, is exploring end-of-life strategies such as repair and reuse, recycling and composting; that way, even if one of its products does end up in a landfill—or buried in the backyard—it will decompose naturally without spewing plastic waste into the ecosystem.

“Since all products eventually end up in the ground someday, we decided to use materials that could safely decompose when they did,” Moss said. “We didn’t need to look farther than the forest floor to see the answers already existed in nature. If we could source 100 percent natural or plant-based materials that have polymer bonds that nature can undo, then our problem would be solved.”

Unless sources cotton from the U.S. and Turkey and corozo nuts from India to produce apparel. It lists all ingredients with each product drop, including threads, trims, embellishments, dyes, and inks. For example, the Plant Power Biodegradable Tee is made from 8 oz. 100 percent cotton interlock fabric, cotton thread, cotton tags and labels. Unless tests all products against the American Apparel & Footwear Association (AAFA) restricted substances list, and only uses water-based dyes free of solvents and plastisol.

Moss says Unless offers a “better way” to operate than the fast fashion “villain” and its plastic-happy status quo.

“Instead of creating more trash, we make products that disappear without a trace,” she said. “Being the world’s first truly regenerative fashion platform means we leave nothing and no one behind. We invested heavily in making quality products that are built from the elements, to be worn in the elements, to be safely returned to the elements. In order to do that, our products must be made with durability, utility and versatility in mind so you don’t have to sacrifice style to do the right thing for the planet. We want to destroy the conventional idea that style will always become trash.”

Lavender stalks

Lavender is more than just a key color this year.

In a cooperative research project that began in 2021, the Deutsche Institute für Textil- und Faserforschung Denkendorf (DITF), the University of Hohenheim and natural cosmetics company Naturamus are testing cultivation methods for lavender in organic farming, suitable lavender varieties and developing energy-efficient strategies for essential oil production.

“Naturamus is interested in producing high-quality essential lavender oil, [the] University of Hohenheim is establish[ing] lavender cultivation techniques for organic farms in south-west Germany and DITF is interested in [the] development of sustainable fibers,” said Thomas Stegmaier and Isabell Hildermann of DITF.

Distilling essential oils often creates plant-residue by-products. DITF is researching how these residues can be used to produce fiber composites and fibers for textiles.

“Large amounts of lavender stalks remain unused after distillation or are only composted,” Stegmaier said. “This inspired us to think about possibilities to use this valuable biomass.”

Fibers for textiles can be obtained from the lavender stem. DITF is already working on testing the raw material and separating the fibers. The fibers are bound together by wood (lignin) and pectin. Researchers use aerobic and anaerobic bacteria, alkaline or acidic solutions and enzymes to break the “glues” around the fibers, Stegmaier said.

“The dissolution of the ‘glue’ was difficult,” Stegmaier said. “Only by combining different technologies with a good temperature setting is it possible to separate the fiber bundles and thus achieve a fiber fineness that can also be used for clothing.”

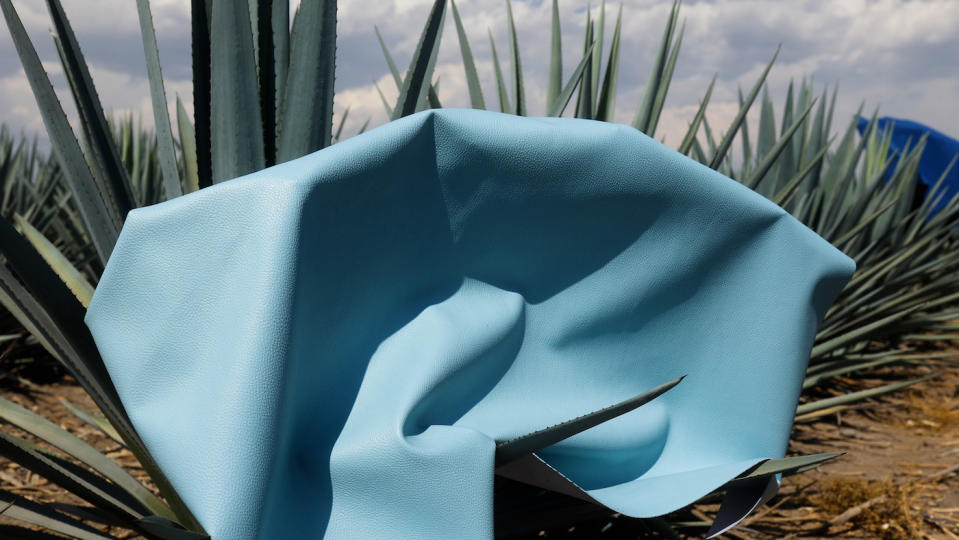

Desserto

Desserto, an alternative leather company known for its cactus-based product, marked its fourth anniversary by launching a new biomaterial by upcycling a tequila industry by-product: Desserto Agave. Described as a “gift from Mexico to the world,” the plant-based material comprises lignocellulosic materials, which play an important role as substitutes for fossil fuels. In the agave, these are made up of 43 percent cellulose and 19 percent hemicellulose.

According to Desserto co-founder Adrián Lopez Velarde, the company’s “latest innovation” upcycles tequila production’s pulpy fibrous “bagasse” waste, into “a material that can be used to make handbags, garments, accessories and furniture.” Desserto Agave, made with up to 80 percent bio-based content, is available “on-demand” for brands whose values “match our sustainability practices,” he added.

“This is a solution that aims to reduce the environmental impact from the tequila and materials industry by offering a plant-based material that is durable and sustainable,” Velarde said.