Jeans Redesign Urges Participants to Think (and Act) Circular Beyond Jeans

With 100 global participants spanning fabric mills, manufacturers, vertically integrated units and brands, Ellen MacArthur Foundation’s Jeans Redesign initiative is arguably one of the most successful industry-wide effort to reduce denim’s impact on the environment.

Founded in 2019, the guidelines set a minimum bar to design and produce denim garments in line with circular economy principles such as durability, traceability, recyclability, and safe materials and processes. Global brands including American Eagle, Gap, Good American, Levi’s, Primark, Ralph Lauren, Wrangler and Zara have unveiled capsule collections that meet the criteria, while mills from Artistic Milliners, Calik and Cone to DNM, Orta and Saitex are among the suppliers innovating behind the scenes.

More from Sourcing Journal

Guess Targets Preferred Materials; Plans Circular Initiatives

Ellen MacArthur Foundation Rolls Out Circular Startup Database

Jeans Redesign’s second insights report (the first came in 2021) found that many denim mills and garment manufacturers already comply with the guidelines, meaning brands have more plug-and-play options when it comes to developing their circular collections.

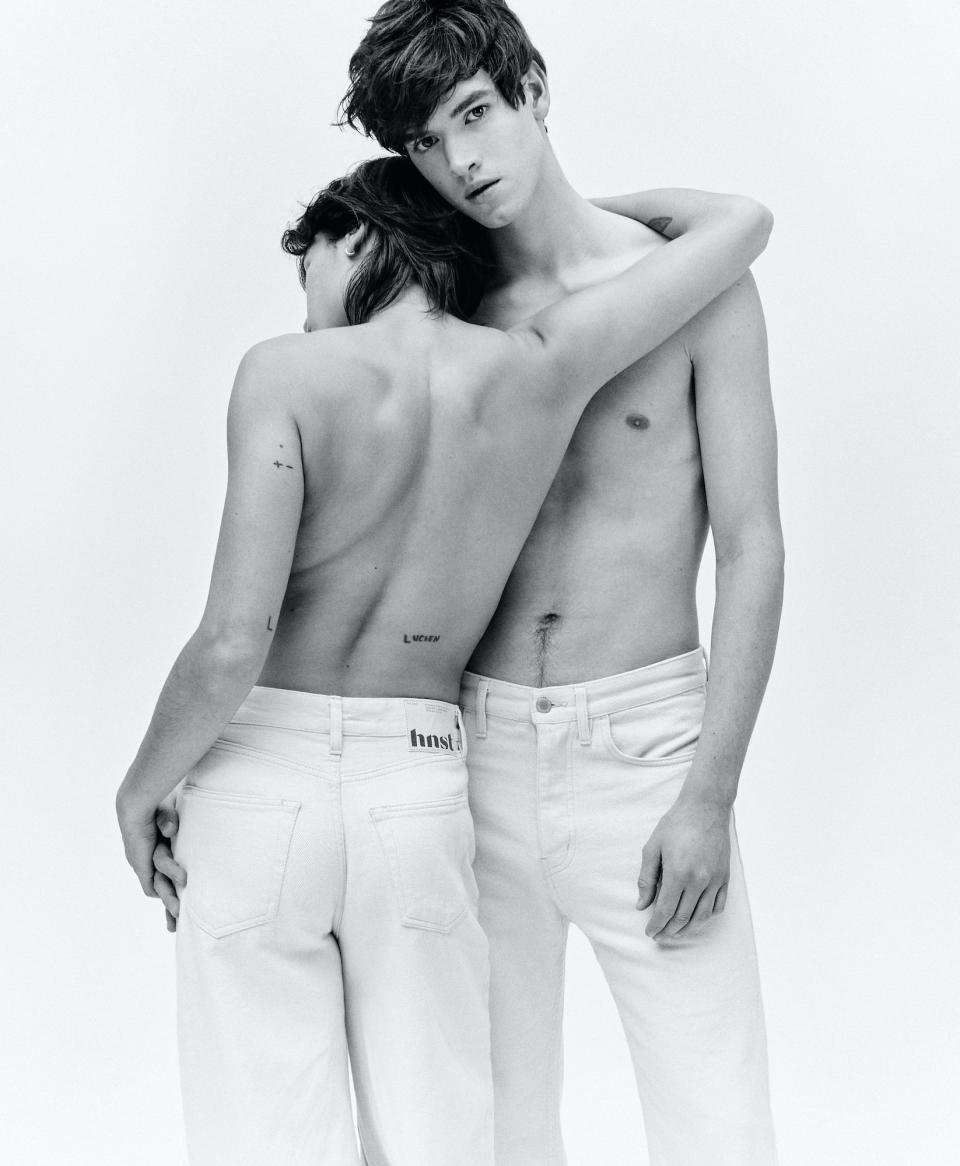

Though it’s just a fraction of the industry total, brands brought 1.5 million pairs of redesigned jeans to the market from 2021 to 2023, more than three times as many as in 2021. The report states that one in nine brands are redesigning at least 40 percent of their jeans assortment to meet the guidelines, and some (HNST and BAM Bamboo Clothing) have reached 100 percent.

Brands are thinking beyond jeans as well, with 38 percent of participants applying the principles to other denim garments like shirts, jackets and dresses.

Jeans Redesign is benefitting from the investments that participants have made to scale their circular production.

One-third of the participant group reports collectively investing over $39 million in areas such as knowledge building, fixed assets, inventory capabilities and M&A to create fabrics and jeans in line with the guidelines. With many participants yet to submit investment data, the report notes that the total investments are likely to be substantially higher.

It’s paying off at retail as brands are seeing Jeans Redesign products sell at a healthy clip.

“Brands reported the average sell-through rate of their redesigned jeans was 78 percent which, according to experts, is higher than the industry baseline, demonstrating the power of the industry to shape desire towards a circular economy for fashion,” the report states.

Garment manufacturers also see a 25 percent higher sell-through rate than the non-redesigned jeans in their portfolio.

Jeans Redesign is not without its obstacles.

Limiting non-cellulose-based fibers to 2 percent is “one of the toughest requirements for participants to meet,” the report stated.

As hard as brands might try to market rigid jeans as a comfortable, durable and timeless option, consumers still gravitate toward stretch. Some brands are finding ways to work in stretch qualities into their Jeans Redesign collections. H&M, for example, reported producing jeans with just 1 percent elastane, and Turkish mill Maritaş Denim said it has initiated research and development to overcome this gap.

Sourcing stitching thread that can be easily disassembled without creating significant fabric waste continues to challenge participants. Solutions are beginning to show their face; however, some require new equipment. For example, made-to-order brand Unspun uses Resortecs’ Smart Stitch thread which is fused at high temperatures. This allows the zipper to be automatically separated during disassembly, but the process requires a specialized oven.

Zippers, in general, are a hurdle. Participants said they haven’t found a zipper solution that can be easily removed and reused or recycled without losing fabric during disassembly. Most participants opted to remove zippers altogether from their jeans. A common workaround is using buttons designed with screw-based disassembly fastenings instead.

As for the future of Jeans Redesign, why stop at jeans?

The report states that Jeans Redesign has succeeded in enabling participants to “acquire and apply key learnings in circular design and help turn ambition to action.” Though 29 percent of brands and manufacturers, like H&M Group and Hirdaramani, have reported applying the principles to non-denim garments (sweaters, tops, and accessories), the flame must be lit for other apparel product categories to “fully capture the economic and environmental value of a circular economy for fashion,” the report states.

The foundation urged more CEOs to support this change of mindset and empower their sourcing and design teams to apply their circularity knowledge to all garments.

Policymakers need to look at the full picture, too. While policies like EU’s Ecodesign for Sustainable Products Regulation define performance criteria for individual products, the foundation said policies must also consider collection, sorting, repair and recirculation. In the meantime, 71 percent of participants are filling that gap by establishing their own collection, resale or repair service programs.

“To make circular design the norm and ensure circular products do not end up stranded in a linear system, an acceleration of policy efforts is required,” the report states.