For India, Textile Waste Is the Next Frontier

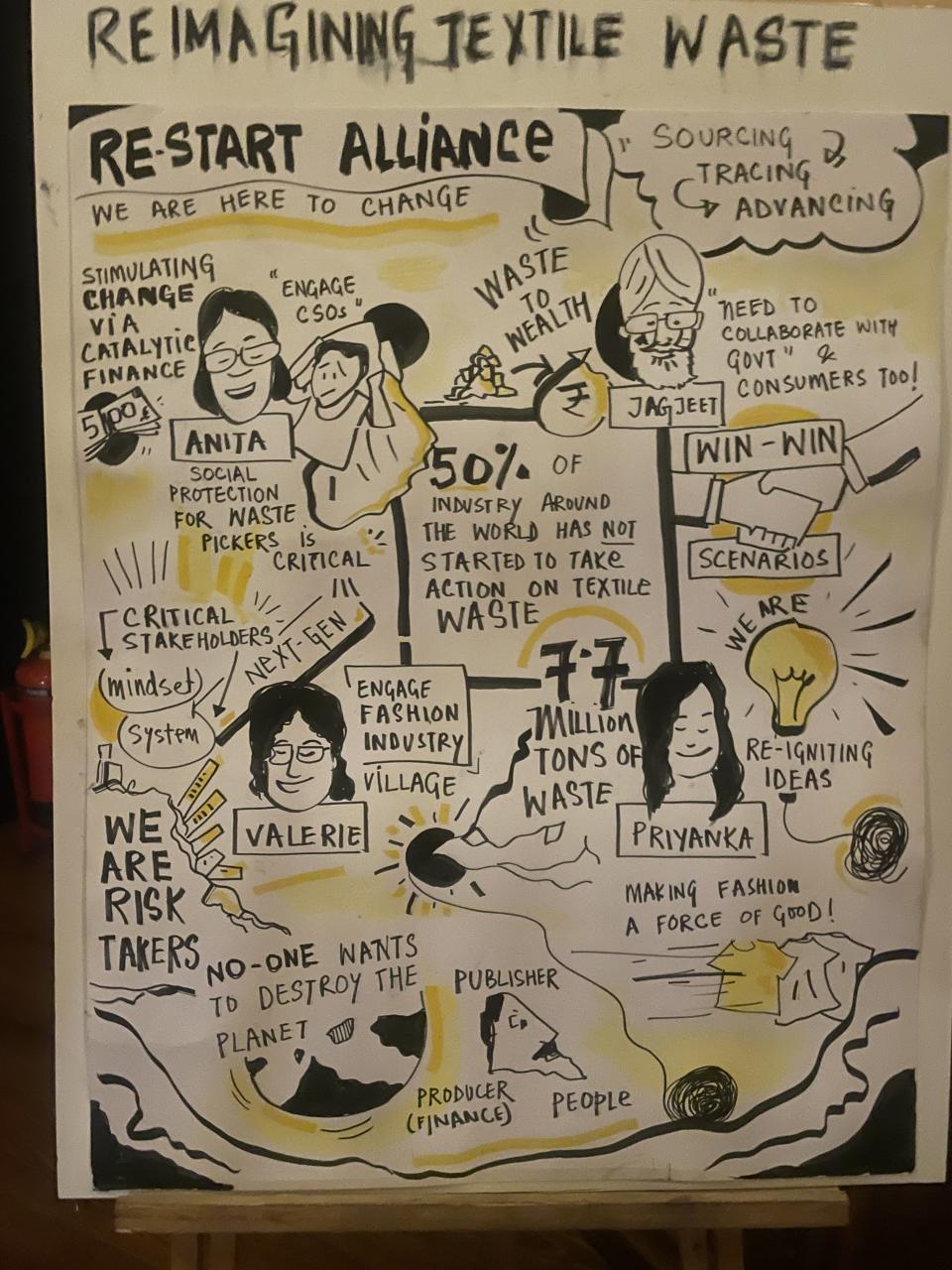

Re-start is an apt name for a new group re-imagining textile waste.

The Re-start Alliance launched last Friday, aiming to position India as a leading next-gen solutions hub for turning castoff textiles into useful products.

More from Sourcing Journal

Living Ink Raises $3.5M to Scale Carbon-Negative Black Pigments

Mango Joining Regenerative Cotton Brigade With New Collection

UConn Researcher Tackles Protein's Possibilities for Plastic

Netherlands-based Fashion for Good and IDH, Canada-based Canopy, and Switzerland’s The Laudes Foundation linked arms on the alliance, which just finished a pilot program and undertook a feasibility study of the financial aspects of processing textile waste.

Restart Alliance decided to kick off in India, where more than 8 percent of the 132 million tons of global textile waste is either generated or shipped. Of this, pre-consumer waste accounts for 3,265 kilotons and post-consumer 3,944 kilo tons; imported waste is approximately 584 kilotons of the total 7,793 kilo tons.

The alliance rang in the future at the “Reimagining Textile Waste” conference on Dec. 1-2, which drew key textile ecosystem stakeholders, recycling experts, and international innovators who look towards India as a pioneering recycling destination.

Speakers pointed to India’s significant potential as a circular recycling region if the nation can address numerous bottlenecks. These include the lack of sorting for cotton and cotton blends, and a growing volume of synthetic blends, and the technologies for advanced recycling.

While announcing the initiative, the four groups noted “none of them had a stake in the supply chain, and that the alliance was about scaling the initiative.”

They urged brands, tech players, the broader industry, and consumers to play a bigger role, with policy makers also encouraged to offer their support.

Prajakta L Verma, joint secretary, ministry of textiles, said she’s looking at policies that could advance the textile waste sector. While noting the drive for textile waste management by hyperlocal entrepreneurs, who are virtually invisible in the textile value chain, supporting textile waste policies has a “lot of implications for the livelihood of the sector,” she said.

“What we can do as policy makers is to support this drive and local wisdom,” Verma said, adding, “circularity is not just mitigation but preventive action. Not just end-of-life-stakeholders, but has to be observed through the value chain. We have to provide linkages to help the fragmentation, lack of visibility, of mapping textile waste flows.”

She credited the Fashion for Good report for exposing her to the textile waste space, but now the ministry was carrying out a pan-India study to see how different stakeholders are channelizing this waste. “This will be ready early next year to help us formulate the way ahead,” Verma said.

According to Fashion for Good’s Wealth in Waste report in 2022, 1,720 kilotons of 100 percent cotton post-consumer domestic (PCD) textile waste are produced in India every year, languishing without proper collection and sorting systems. With the coming surge of textile waste management legislation, the value of post-consumer waste is expected to rise, making it crucial for India to focus on PCD waste and develop the necessary infrastructure for collection, sorting, and pre-processing.

The financial component was also addressed with the official launch of the IDH report, “Unveiling India’s Textile Waste Landscape: a Cost Analysis.”

IDH has also spent more than 10 years as the strategic partner for the Better Cotton Initiative (BCI) and intends to apply learnings on pre-competitive collaboration and scale to the textile waste problem.

The conference also marked the completion of Fashion for Good’s November 2021 pilot program, which aimed to understand both the pre-consumer and post-consumer textile waste streams in India, and to trial sorting and mapping solutions. This resulted in a tool kit designed to revalorize textile waste in India, and marked the closing of the Sorting for Circularity India Project.

The project was designed to build the infrastructure needed to support greater circularity, and unite industry players including Fashion for Good partners Adidas, Levi Strauss & Co., PVH Corp., Arvind Limited, Birla Cellulose and Welspun India. Reverse Resources offered technology assistance.

Both The Laudes Foundation and IDH funded the Fashion for Good Circularity report.

“We are excited to move beyond rhetoric with this powerful coalition of partners and translate our findings into a roadmap for concrete actions,” said Katrin Ley, managing director, Fashion for Good.

The Sorting for Circularity India Project Post-consumer Pilot Program conducted several trials with Fashion for Good innovators Matoha, PICVISA, and Reverse Resources, as well as Greenworms, Saahas Zero Waste, Uptext, and Hasiru Dala Innovations as the sorters, and Arvind Ltd., Usha Yarns, Vardhman Textile Ltd., Kakkar Spinning Mills, and Kay Gee Enterprises as the recyclers. In parallel, Sattva and Circle Economy Foundation assessed the commercial viability of sorting hubs using these technologies.

The pilot worked with 33 tons of textile waste, exploring innovative sorting technologies, the nuances of post-consumer waste, and the potential for a closed-loop system in India’s textile industry. The business case assessment explored the infrastructure and investment requirements, the scenarios of financial success and the roadblocks, serving as a framework to enable well-informed decision-making for sorting hubs to implement these technologies.

Among other big takeaways from the conference, Fashion for Good and Canopy stated their Indian ambition of scaling 1 million tons of recycled textiles focused on poly/cotton blends, which today make up about 25 percent of the textile waste stream and often end up landfilled or burned. Some 1 million tons is part of their push to stimulate 12 million tons of alternative fiber production in India over the next decade for paper packaging and textiles.

But what else must India do to realize this waste-as-resource future?

If it “takes a village to raise a child, it needs a fashion village to raise a new textile,” said Valerie Langer, fibre solutions strategist, Canopy, adding that some stakeholders question “how to move ahead in sync as competitors.” The answer clearly was to move to the ‘pre-competitive space’. Details of a more structured plan ahead by Re-Start is expected to be announced in the coming months.