Hoist the Mainsail and Watch a Master Craftsman Create a Ship in a Bottle

Ships come in many shapes and sizes—including ones that fit in bottles.

No one knows this better than Jim Goodwin, a retired geologist who for 25 years has been perfecting the maritime tradition of fitting pint-sized keels, hulls, and top sails inside glass bottles. As the proud owner of Carolina Ships in Bottles (a shout-out to his home state), Goodwin is a self-described textual kinesthetic, meaning he’s a bit of a fidgeter. So for nearly a quarter-century, he’s kept his hands busy crafting ships of all types—whether the notorious pirate vessels, famous U.S. frigates, or the many other famous ships-of-line that navigated the world’s oceans during the Age of Sail—placing them snugly inside their own glassy worlds.

Goodwin started out making model ships sans bottles, but eventually decided to take his ship-making skills a step further by building his first ship in a bottle.

“I started out in December of 1999 when a friend of mine suggested that I try it,” Goodwin tells Popular Mechanics. “So I read two books and I got hooked on the engineering aspect of having the mast collapse, as well as building the vessel so that it would insert into the mouth of the bottle and then [raise] the mast up and [make] sure that it would fit inside the bottle.”

The first ships in bottles date back centuries, though these original creations were actually placed in bottles with the spout pointing downward—not on the side as is usual today. The craft really exploded in the mid-19th century when improved glassmaking made bottles thinner, more even, and free of air bubbles that would otherwise distort the image of the model inside.

There are two primary methods for constructing a ship in a bottle. Some artisans use long, thin tools to construct the ship entirely within the bottle, but the most common technique—the one championed by Goodwin—is what’s called a “flatpack” approach, wherein masts along with other pieces of the vessel collapse down on a hinge so it can fit inside the neck of the bottle.

If you want to make your own ship in a bottle, you’re going to need a bottle, of course. Goodwin jokes that one of the best parts of the process can be the emptying of a bottle. He especially likes whiskey bottles because they tend to provide ample room for the masts. With (empty) bottle in hand, you’re then going to need a ship. After creating nearly 3,000 ships in bottles, this part can get a bit tricky even for Goodwin.

“There are so many sailing ships throughout history and finding one that’s new to me … that’s challenging right there,” Goodwin says. “I get a lot of demand for pirate ships because people like the outlaws … But as a bottle craftsman, I like the clipper ships because they have five sails per mast and just getting that through the mouth of the bottle and racing it out and seeing all those sails … it’s impressive.”

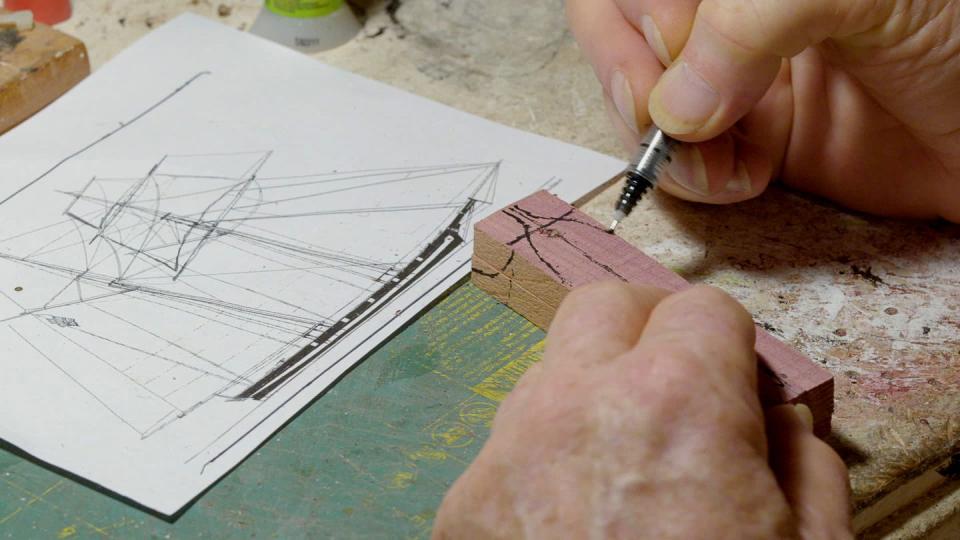

Goodwin says about 85 percent of the shipbuilding happens outside the bottle. The hull of many of his creations are made from Carolina red cedar. Then, he adds on the decking and other sailing accoutrement, including gunports and cannons. For the mast, Goodwin goes with walnut because the tight-grained hardwood means Goodwin can drill very fine holes without issue.

For sails, Goodwin goes with a cotton resumé paper, which holds its shape and color better than other kinds of paper; sometimes he’ll stain the paper with coffee grounds to give the sails a darker hue. He then places some flags and then adds heavy craft thread to mimic the tarred rigging on old sailing ships. Once plasticine clay is placed in the bottle to mimic the ocean waves (and a space carved out for the ship), the masts collapse down 45 degrees to fit through the bottle’s neck.

Then comes the moment of truth.

“Once [the ship is] in, you pull the strings to raise the mast, glue the two pieces together, the upper hull to the lower hull, and then you go through the process of removing the strings,” Goodwin says. “It’s always amazing to me when you insert it and get it inside the bottle and raise the mast and everything fits perfectly.”

Goodwin says he’s proud to carry on this long-standing maritime tradition and hopes to pass on his techniques to a new generation of model ship-builders. While only a couple dozen or so creations away from his personal goal of 3,000 ships in a bottle, Goodwin says he has no desire to relinquish the helm quite yet.

“I will probably go to my grave … with a ship in my hand or a bottle tool in my hand,” he says. “It’s in the blood.”

You Might Also Like