The History of Chewing Gum, From Chicle to Chiclets

How chewing gum is made and the surprising history that gave birth to gumball machines, bubble gum, and beyond.

I don't think about gum all that often. I guess most people don't. I do have a strong preference for a certain brand (as I write this, there are about a half dozen wadded-up Orbit Bubblemint wrappers scattered all over my desk), but I've never considered what's in it. Why would I? Chewing gum is one of the most mindless things we do as human beings. I'd venture to say most of us don't care what goes into it, or how it's made.

But should we? It's a question I started asking myself recently while driving from my home in Brooklyn to visit friends in upstate New York. Just past Yonkers, I found myself gnawing on the same stick of gum I'd popped in my mouth an hour earlier, even though it was long past its prime. As the minty flavor gave way to nothing at all, it hit me that what had once been a sweet, stretchy confection was starting to feel more like Silly Putty: sad, gray, and unmistakably synthetic. "What the hell is this stuff?" I wondered, as I wrapped it up and stowed it away in that car door compartment that seemed like it was designed expressly for discarded gum wrappers, sticky pennies, and rotten banana peels.

I decided to look into it.

Why We Chew Gum

The practice of chewing gum dates back thousands of years, its enduring popularity evident in the dried chicle (a natural gum derived from trees) found among Mayan ruins in southern Mexico and the thousands of grayscale ovals pressed into city sidewalks around the world. But why we chew gum is a matter of conjecture. Some say it's a way to stave off hunger, deal with stress, or even improve our memory. I read that during the world wars, Wrigley chewing gum was included in military rations, as it was believed to help soldiers with their stress, thirst, and hunger. A 2002 study claimed that chewing gum "significantly improved performance on standardized tests of working memory and episodic memory (immediate and delayed word recall)." And a study in 2004 similarly found that the act of chewing activates some of the same neural circuits that help form memories. Meanwhile, a University of Rhode Island study found that gum can act as an appetite suppressant, greatly reducing the number of calories we consume, because chewing it stimulates the nerves in our brain responsible for satiety.

While I've never relied on gum as a performance-enhancing drug or weight-loss tool, I do find that chewing helps reduce my stress levels, especially when I'm past deadline (yes, I'm chewing a lot of gum right now). And, because I work from home—or, more specifically, from my kitchen table—it distracts me from raiding the fridge every 15 minutes for cold pizza and Diet Coke. Occasionally, it even lets me wow my hard-to-impress two-year-old daughter with my mad bubble-blowing skills. But this story isn't so much about why we chew gum as it is about what gum is—and where, exactly, it came from.

How Gum Is Made

Serious Eats / Library of Congress

As it turns out, the process of manufacturing gum is pretty simple. So says Joan Mestres, coauthor of the wonkily titled Formulation and Production of Chewing and Bubble Gum. The basic steps include mixing the ingredients (more on those in a moment) in what's known as a sigma mixer, which kneads the gum until it takes on the consistency of bread dough. It's then extruded from the mixer, rolled into sheets or small blocks, cooled, cut, and packaged.

The manufacturing of gum may be simple, but those ingredients are another story. Gum base itself is made of three things: a resin for chewiness, wax for softness, and elastomers that maintain its elasticity. While early chewing gums were made from tree-based resins and natural waxes, these days, both ingredients are synthetically derived from petrochemicals. In other words, the gum you chew is essentially plastic and rubber. According to the Washington, DC–based International Chewing Gum Association, gum is so shelf-stable that there is no law requiring an expiration date for it.

Of course, it's a bit more complicated than that. Natural and artificial waxes, which act as lubricants between strands of polymers, are sometimes combined to give the gum a better consistency. Other gum ingredients might include natural and artificial flavors; emulsifiers, which keep the gum soft; antioxidants, which keep it fresh; and humectants, like glycerol, to keep it moist. Then, of course, there are sweeteners, both natural and artificial.

The reason I can capture my daughter's attention with those huge bubbles I blow is thanks to a high proportion of the aforementioned elastomers—either natural or synthetic latexes—added to bubble gum bases. According to John Emsley, author of Vanity, Vitality, and Virility: The Science Behind the Products You Love to Buy, bubble gum is often made with styrene-butadiene (SBR), a food-grade polymer that swells when it comes into contact with saliva, or food-grade butyl rubber—oddly, the same stuff that's used to make bicycle inner tubes.

Reading over the ingredient list of my mainstay sugarless Orbit Bubblemint, I noticed that artificial sweeteners occupied the lion's share of the text. In fact, it contains a virtual cocktail of the stuff, including sorbitol, mannitol, aspartame, acesulfame K, sucralose, and xylitol. Other ingredients on the list: glycerol, the above-mentioned humectant; soy lecithin, an emulsifier; the antioxidant BHT (butylhydroxytoluene), a synthetic preservative that's also used in rubber and—gasp—embalming fluid; and colors and flavors both natural and artificial.

Of course, the most important quality to most of us gum-chewers is that last one: flavor. Throughout your lifetime, you've no doubt been inundated with ads touting a gum's "long-lasting" flavor, a quality scientists and gum manufacturers have spent decades trying to improve, with good reason. As Mestres points out, "What other foodstuff remains in the mouth for a long time, like chewing gum does?"

One solution, according to Mestres, is using varying concoctions of natural and artificial flavors with different degrees of solubility, so that "waves" of flavor are released in our mouths as we chew. "A clear example [is gums] with flavor particles or crystals," he says. "When we break the particles, there is a sort of burst that enhances the perception of the taste." Another way to manipulate flavor is by playing with the sweetness profile of each gum, which affects how we perceive the flavor. In other words, once the complementary sweetness is gone, that watermelon bubble gum you're chewing will lose most of its lusciousness.

This is a phenomenon I seemed to understand on a base level even as a kid. Back then, I often took the gum I was chewing out of my mouth, rolled it in sugar, and placed it in the freezer for future use. (It tasted okay, but my mother, practically dry-heaving each time she opened the freezer, eventually put the kibosh on this practice.)

According to Mestres, the main problem with flavor loss isn't the gum itself but our own mouths. Part of the reason gum loses flavor, he says, is that the receptors on our tongues become saturated to the point that, after a while, we simply don't taste it anymore. He claims that if we remove the gum we're chewing for a few minutes, take a sip of water to clear our palate, and start chewing the gum again, we'll find it has more flavor than we previously detected. Still, over time (anywhere from two to five minutes, based on my own unscientific research), our saliva absorbs both the flavoring and the sweeteners, leaving us with a flavorless wad that, unless you're a certain White House press secretary, eventually gets discarded.

They Don't Make It Like They Used To

Serious Eats / Library of Congress

Until recently, I assumed the gum I chewed was at least kind of natural. Sure, I suspected it contained a 21st-century combo of artificial colors, preservatives, sweeteners, and flavors, much like the one just described. But I mistakenly thought the base itself was derived from a naturally occurring something-or-other.

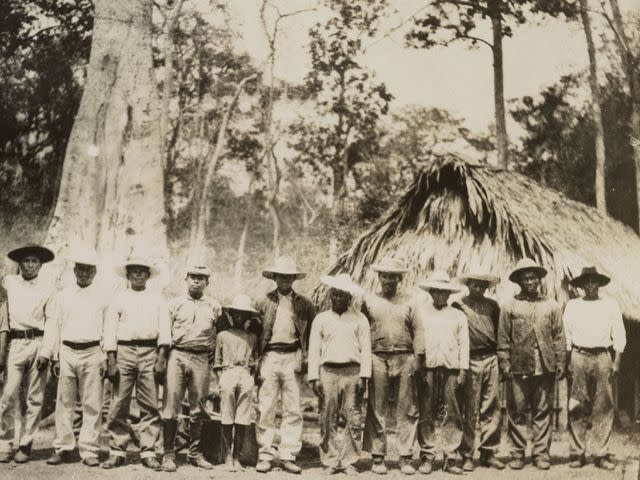

For years, that was true. Until around World War II, most gum came from the sapodilla trees that grow in the rainforests of southern Mexico and Central America. Workers known as chicleros would scale them and cut zigzag patterns into the bark on their way down. In response to the carving, the trees would secrete a Band-Aid of sorts—that chicle I mentioned above. As the natural latex ran down toward the base, it was collected in small pots; once those pots had filled, the chicle was dried, transported through the forest by rail, and sent to, say, the Wrigley Company in Chicago (established in 1891) or Adams Sons & Company in New York (founded in 1871).

I learned all of this from Jennifer Mathews, an associate professor of anthropology and author of Chicle: The Chewing Gum of the Americas, From the Ancient Maya to William Wrigley. The connection between her field and the name of the book is simple: The Mayans loved chewing chicle. They started gnawing on it as early as the year 200, to freshen their breath or work the maize out of their teeth. But they weren't the first to fall in love with chewy saps and resins. Mastic, a resinous substance produced by a tree native to southern Europe, was chewed by the ancient Greeks; the Scandinavians chewed birch sap; native North Americans gnawed on the sap of the spruce tree. But the Mayans' love of gum was different—something akin to a present-day American's love of cheeseburgers, or a German's love of beer.

Later, the Aztecs would also take up the practice of chewing chicle, though they were far more rigid than the Mayans about who could chew it. "Only kids and old ladies could do it publicly," Mathews told me. "Men who chewed chicle were seen as effeminate, while younger women who indulged were assumed to be prostitutes. Anyone of adult age who chewed it was considered totally vulgar."

Gum in America

Serious Eats / Vivian Kong

In the United States, European settlers picked up the habit of chewing spruce from Native Americans as far back as the 1600s. But it wasn't until 1848 that a New Englander named John B. Curtis started selling it commercially. His Maine Pure Spruce Gum, and its natural spruce taste, became enormously popular. He eventually started making gum with paraffin wax, instead of difficult-to-source sap, and flavoring it with ingredients like sugar, licorice, and vanilla.

Curtis maintained a monopoly on the gum industry for decades, until a man by the name of Thomas Adams entered the picture. Adams was a New Jersey inventor who, in the 1870s, found himself in an unlikely business partnership with 11-time Mexican president General Antonio López de Santa Anna (yes, the one from the Alamo) during the latter's exile to Staten Island. Determined to return to power once more, the general tapped Adams, who was assigned to him as a secretary, to help him in his efforts to vulcanize chicle, with the goal of making a rubber substitute that could compete with the likes of Goodyear. If he could pull it off, the fallen general hoped the profits would help finance an army, allowing him to win back the presidency. It didn't work.

After much trial and error, Santa Anna gave up on the idea and went back to Mexico, where he did eventually return to power. But Adams, who'd picked up the general's habit of chewing chicle, decided to take a different stab at glory. Working out of his kitchen, he boiled the chicle down, dried it, rolled it, cut it into sticks, and took it to a local drugstore where customers, mostly children, purchased Curtis's wax gum. It sold out within hours.

By 1871, Adams had patented a machine for making chewing gum sticks. By the 1880s, according to Mathews, he was selling five tons of gum per day. One of Adams's most popular gums was Black Jack, which remained popular until the 1970s, and which you can sometimes still find at retro candy stores today. He eventually added natural spearmint and tutti-frutti flavors.

Serious Eats

Adams's success generated many imitators. In 1899, a New York pharmacist named Franklin V. Canning introduced Dentyne ("dental" + "hygiene" = Dentyne), with promises of preventing cavities. One year later, a peppermint-flavored, candy-coated gum called Chiclets hit the shelves. "They took what they knew about Jordan almonds and applied it to gum," Mathews says. "Adding that hard candy coating also preserved the gum for longer periods of time." (Adams's company eventually bought Chiclets, which became one of its most beloved brands.)

Of course, the most ubiquitous candy-coated gum is the gumballs we still see in vending machines in just about every grocery store in America. Legend has it that they were invented by a New York grocer who, dissatisfied with his sales of stick gum, wadded a bunch of it up and tossed it into a barrel of sugar. But, as with a lot of food origin stories, there's no solid documentation to back it up.

That's not the case with bubble gum, which traces its origins back to 1928, when a man by the name of Walter Diemer invented the stuff that bubble-blowing competitions and baseball card collections are made of. Diemer was an employee of Frank Fleer, whose company started making chewing gum around 1885. A consummate capitalist, Fleer wanted to sell something different from his rivals and spent years working on a product that could be blown into bubbles. In 1906, he concocted a bubble gum he called Blibber-Blubber, but it proved too sticky to market. After much fiddling with Fleer's recipe, in 1928 Diemer struck gold with a bubble gum that's still sold from candy jars all over the world: Dubble Bubble.

William Wrigley, the most famous man in the gum biz aside from Adams, entered it pretty late in the game. While he started selling his gum in the 1890s, it wasn't until the early 1900s that he began to change the industry forever. "Wrigley is an interesting guy," Mathews says. "He started out as a soap salesman, and one of the things he learned is that you need to advertise—and he was a master at advertising. He put up billboards everywhere, and in 1915, he sent four sticks of gum to everyone listed in the US phone book—that's 1.5 million people!"

The success of Wrigley's and Adams's chicle-based chewing gum started taking its toll on those Central American forests, which weren't ideal producers for massive human consumption. According to Milton, sapodilla trees can be harvested only once they are around 20 years old, and each yields only about a kilogram of gum per tapping, which occur every three or four years. A 2009 Smithsonian article, drawing on Mathews's research, noted that poor harvesting methods resulted in the loss of approximately a quarter of the sapodilla trees in Mexico by the 1930s. Faced with a shortage of chicle, chewing gum manufacturers started switching to synthetic, petroleum-derived bases, essentially introducing Americans to the modern-day gums we chew today.

Serious Eats

Back to Basics: Modern Gum and Sustainability

While almost all contemporary chewing gum is made with these synthetic bases, there are exceptions. Several small-scale gum companies are using sustainable practices to reintroduce chicle-based gums to American consumers. One of them is Glee Gum, based in Providence, Rhode Island. Owner Deborah Schimberg says the inspiration for her gum came from Ben & Jerry's Rainforest Crunch ice cream, which helped contribute to Central American economies by creating a new market for exotic nuts. While in Guatemala on a Kellogg Fellowship in the early 1990s, she developed an extreme fondness for sapodilla trees, and came to believe that, if she did things right, they could be tapped for their precious chicle once more.

"It is an extraordinary tree," she tells me. "Very big, with a hard wood, sort of like mahogany." Schimberg also thinks the "gum" that comes from these trees is simply better than artificial gums, which "just aren't very appetizing—chewing [them] is sort of like chewing on those paraffin wax lips they sell at candy stores.... Chicle, on the other hand, has this natural combination of waxiness and rubberiness that creates a perfect mouthfeel." During her fellowship, Schimberg began working with her children to see if they could make chicle gum at home. "We had our seven-year-old daughter, my five-year-old son, and my six-month-old baby at the kitchen table working with the gum base, which was very sticky and messy," she recalls. But in the end, she found that it was pretty easy. After melting down the chicle, which you can buy online, she mixed it with natural flavorings, like strawberry and mint. Voilà! Homemade chewing gum.

Picking up a bag of Glee bubble gum at a neighborhood market the other day, I popped a few of the candy-coated pellets in my mouth and began to chew. Unlike regular gum, it had a smoother, almost velvety feel to it. The flavor didn't last as long as it does in the stuff I normally chew, but I found the chewing experience to be far more pleasurable. The gum was softer, more pliable—more natural. Walking home, I started thinking about all the plastic and polymers I've been chewing all these years. Though I'll probably continue to chew them (ain't no way I'm giving up my Orbit), I'll also consider how ancient the practice is. I will picture those big sapodilla trees down in Mexico that made it possible. More than I ever did before, I'll think about it.

July 2017

Read the original article on Serious Eats.