Harnessing the Power of Digital: Textile Companies Embrace Fashiontech Solutions

MILAN — Over the past 10 years, the textile industry has been pressured to take significant steps toward digitalization and sustainability, both viewed as key in adapting to continued disruption.

The two aspects are often intertwined. Streamlined operations and workflows, courtesy of computer technology, can help reduce environmental footprints, while embracing sustainability, and sophisticated digital efforts are needed for traceability.

More from WWD

EXCLUSIVE: Syky Enlists Nicola Formichetti as Artistic Director

Slow Fiber Movement Charts Radical Approach to Sustainability

Crisp, Airy Yarns Dominate Spring 2025 Collections as Spinners Ready for Dampened Outlook

When the pandemic hit, all of the above came to the fore, as both digital tools and sustainability were seen not just as competitive advantages, but as part of a survival toolkit.

Here, WWD spotlights high-tech solutions and fashiontech companies seen driving change on both fronts.

Temera

As traceability has largely replaced sustainability in the ongoing conversation about responsible business practices, Temera has become an ally of fashion players aiming to implement traceability.

Founded in 2009 in Florence and acquired in 2022 by Beontag, a global supplier of Internet of Things (IoT) technology, Temera provides fashion and luxury brands and supply chain players with digital twins to their physical products, harnessing a blockchain-based technology to enhance upstream and downstream traceability.

In addition to enabling sustainability, digital twins are viewed as valid instruments to gain a competitive advantage because they enhance real storytelling about marketed product; help shorten time-to-market and manufacturing accuracy; help combat the gray market, serving as proofs of authenticity, and can unlock after-purchase services for customers.

By embedding RFID tags in each product, the latter becomes digitally identifiable and traceable along the pipeline. The use of IoT devices such as QR codes and NFCs, or near field communication, also ensures that customers can have access to sustainability and traceability information.

Temera technology allows companies to implement the Digital Product Passport across their assortments, a requirement at the center of the debate on a European level as part of the textile- and fashion-centric ambitions within the continent’s Green Deal policy. The tool is also considered the sole solution to fully embrace the circular economy.

Providing companies with different tier of services covering each product’s life cycle, from sourcing of raw materials to manufacturing, logistics, retail and upcycling, Temera has become a European leader in RFID technology for the fashion and luxury sectors. In 2023 it generated 24 million euros in sales.

“[Implementing] digitalization equals becoming more sustainable,” said Temera’s chief executive officer Francesco Pieri. “The operational aspects of the Digital Product Passport keep evolving, but in its first iteration [the tool] can already highlight the product’s sustainability, environmental and recycling credentials, as well as its production process and provenance,” he added.

Among its marquee clients, Temera boasts a recent partnership with Tod’s, which conscripted Temera for the implementation of an NFC-enabled Digital Product Passport on its signature Di Bag.

S-iR’s i-Fabric

At the peak of the pandemic, fabricmakers lamented remote work, which cut off the look-and-feel aspect that’s so pivotal when sampling textiles.

Fast-forward to back-to-IRL business, and digital showrooms are still a thing — no longer replacing the physical experience, but flanking it and providing additional customer service throughout the year, beyond trade shows and sales campaigns.

S-iR, or Sense Immaterial Reality, has been at the forefront of innovative digital features, providing realistic digital counterparts to physical experiences and products.

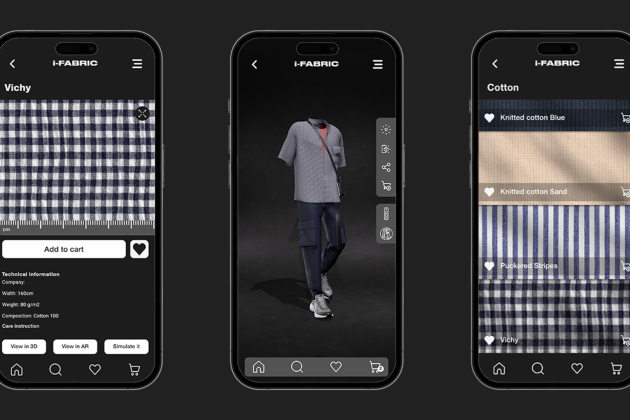

Among its roster of services, the i-Fabric proprietary tool manages to replicate fabric features, including weaving details, patterns, textures, colors and finishings, with a good level of approximation to their physical alter egos.

Viewed as a tool to expand market reach and simplify the sale process, it combines fabric simulation, 3D garment previewing through AR, as well as real-time fabric availability checks, linked with the adopting company’s stock system.

Mindful that digital sales campaigns can be accompanied by lower conversion rates, S-iR has built easy-to-adopt user interfaces allowing company to turn a fabric into a 3D digital asset within one minute through its MagicBox technology.

The tool comes with a sustainable silver lining, too, in that it avoids sample catalogues needing to be shipped to clients.

The company boasts a partnership with the Marzotto Group for its Fratelli Tallia di Delfino and Tessuti di Sondrio labels. The former has embraced the solution for its Gentleman’s Wardrobe service, providing clients the chance to shop in-stock carryovers directly from a smartphone, while the latter has adopted the digital catalogue provided by S-iR across its assortment. Also CLASS, the Milan-based international platform that connects key players in fashion and provides the resources they need to realize sustainability, has tapped into i-Fabric to digitize its clients’ offering.

Last year, S-iR tapped Art Zuijderwijk as CEO, tasked with spearheading its internationalization process. The company, which also provides services including digital and interactive shopping windows, branded spaces and digital trunk shows, counts Christian Louboutin, Foot Locker, Eurojersey, ADI Design Museum and Triennale Milano among its clients.

CLO 3D Design Technology

Beyond digital fashion and avatar outfitting, software-enabled 3D design and prototyping have been a norm in daily creative practices in the industry for at least a decade.

Cologne, Germany-based ColorDigital GmbH, founded in 2013 by former computer scientist Olaf Kölling and designer Gerd Willschütz, has been at the forefront of digital color and texture development through a proprietary cloud platform called DMIx, an end-to-end toolset digitally stocking materials, trims and accessories, with enhanced color and texture output.

In 2020, it linked with CLO Virtual Fashion, a 3D garment simulation technology, to debut CLO, a software integrating all different aspects in the creation of 3D designs, which allows designers and brands to seamlessly interact with manufacturers and translate their creative vision into end products with accuracy.

CLO offers the opportunity to design intricate and multilayer garments, from simple blouses to outerwear with complex patterns. It provides advantages not only in the design-to-manufacturing workflow but also from a business standpoint in that it helps accelerate time to market, minimize production waste and the need to produce and ship physical samples.

Among CLO’s partners, interlining specialist Chargeurs PCC is the sole inner component partner to CLO. “As a leading company operating globally on five continents, our mission has always been to act as pioneers and game changers, playing a leading role in the sustainable transformation of the textile industry through new technologies and digital innovations,” said Gianluca Tanzi, Chargeurs PCC chairman and CEO. “That includes pursuing more strategic partnerships like our collaboration with CLO, which allows designers to easily add our interlining products to their digital iterations, reducing the need for physical sampling, therefore reducing carbon footprint, costs and waste,” he added.

Reda’s Tailoor

An early advocate of the digital transformation, Italian textile group Reda has turned tables becoming itself a fashiontech solution provider.

Not only it invested in digital tailor Lanieri in 2020, but since 2022 it has been marketing the white label technology Tailoor, allowing brands to offer customized and made-to-measure products online to end customers.

The AI-powered 3D configurator can be fully integrated in any brand’s e-commerce site, with a full personalized look and feel. It is designed to integrate brands’ omnichannel services, collect customers’ data and manage orders, schedule IRL appointments and video consultations to finalize the transaction.

Product-wise, the technology, already embraced by marquee fashion brands the company cannot disclose, as well as tailors, gives customers potentially endless personalization options from materials and colors to style, fit and details. Its flexibility allows brands to unlock different personalization tiers across multiple details of any given garment.

Best of WWD