Everything You Need to Know About Different Types of Plywood

Branislav / Getty Images

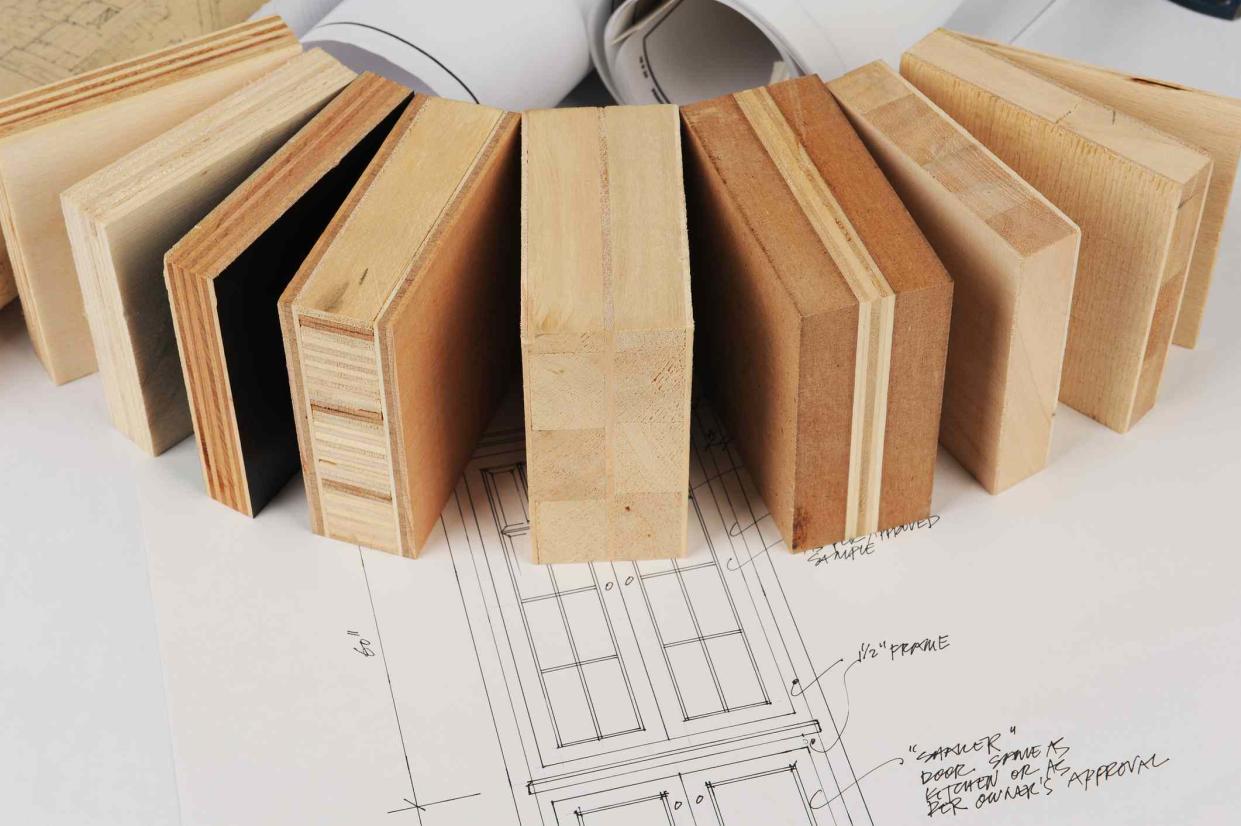

Plywood is a commonly used material in a wide range of construction projects, including furniture-making, deck-building, exterior home construction, interior home construction, and custom woodworking. Plywood is a type of engineered wood that is made by gluing together several thin layers, which are called plies.

The plies are oriented and attached with alternating right angles in order to create a strong durable cross-grain pattern. One of the reasons it's used so widely is because it resists shrinkage and expansion caused by moisture.

Learn more about the various types of plywood to ensure that you choose the best type of plywood for your project.

Types of Plywood

Aircraft Plywood

One of the best types of plywood is known as aircraft plywood. This type of material is made using hardwood boards which are ideal for resisting both heat and moisture. By creating aircraft plywood using very thin veneer layers, manufacturers can keep the plywood light and flexible, while increasing the overall strength of the material.

While aircraft plywood isn't commonly used for home renovation or construction jobs, this combination of strength, durability, flexibility, and light weight, makes aircraft plywood ideal for building airplanes, boats, and tough furniture.

Softwood Plywood

Softwood plywood is constructed using high-quality softwoods, including redwood, cedar, and pine. While softwood plywood isn't as tough or durable as hardwood plywood, it can still be used for roof sheathing, home subfloors, or exterior frame sheathing.

Depending on the ply layers, grade, and ratings, some softwood plywood can also be used to make tool sheds, shelves, and other small woodworking job. Softwoods tend to be easier to cut, sand, and shape, so this type of plywood is often a good choice for custom woodworking projects.

Hardwood Plywood

Using hardwoods, like birch, maple, or oak, manufacturers create a strong, reliable hardwood plywood. This type of plywood is tough and durable due to the hardwood construction, which makes it a good choice for any furniture-making projects or even for some structural construction jobs.

Hardwood plywood may be heavier that other types of plywood, but this same density and strength is necessary when using hardwood plywood to support heavy structures or to make lasting load-bearing frames. Just keep in mind that hardwood plywood isn't as malleable as softwood, so it may be more difficult to cut, sand, and shape.

Exterior Plywood

The plywood that is commonly used to help build and finish the outside of a structure is known as exterior plywood. This type of material is designed for long-lasting weather-resistance, mold-resistance, and rot-resistance, ensuring that the building remains in good condition for years to come.

Given that this plywood must hold up in a variety of weather conditions, manufacturers typically use waterproof and weather-resistant adhesive during exterior plywood construction. High quality exterior plywood can be used to make strong wood frames, beams, and flooring.

Structural Plywood

Structural plywood is designed to be both strong and weather-resistant. This type of plywood is also known as sheathing plywood, due to it's common use as a frame sheathing material. Manufacturers use strong, waterproof adhesives to glue the plies together, creating a tough, durable, and long-lasting material.

Structural plywood is not intended for fine woodworking or furniture-making projects. This is because structural plywood typically comes in C or D grades. The unsanded, unfinished wood isn't overly attractive, but it does provide a high level of durability and support for the exterior of the home.

Flexible Plywood

While exterior and structural plywood specialize in strength and durability, flexible plywood is valued for its utility. Flexible plywood is a very thin, flexible material that is often used to make curves or bends in construction frames or furniture. Historically, flexible plywood was even used to make stovepipe hats due to the light weight of the material.

This type of plywood is manufactured with several thin plies, including a cross-grained central ply and two thicker cross-grained plies on either side. Some manufacturers offer flexible plywood with a decorative overlaid wood veneer to create an attractive, glossy surface.

Lumber Core Plywood

Some plywood options, like flexible plywood, may not work well with screws and other fasteners, but lumber core plywood is designed specifically for projects that require these fasteners. Lumber core plywood has two exterior veneers of hardwood to form the outer layers of the material.

The inner core is made from tightly glued-together strips of wood, forming a solid slab that has an easy time grasping screws. Though, it's important to invest in high-quality lumber core, otherwise the core of the material can contain gaps or voids that weaken the plywood.

Marine Plywood

One of the most durable plywood options is marine plywood. It is constructed of a high-grade plywood and glued together with strong, waterproof adhesives. Typically, marine-grade plywood will be listed as grade A, making it an attractive finishing material for plant boxes, benches, decks, or gazebos.

The water-resistant construction will help keep the plywood in good condition, though you should still paint or stain any plywood that you install outdoors. Otherwise, the marine plywood may be damaged by UV radiation, insect infestation, mold growth, or rot.

Markerboard Plywood

Markerboard plywood is a special type of plywood that is valued for utility purposes. It is made using plywood panels that have been coated with a writing surface that can be used with dry erase markers. This design makes it a great choice for markerboard walls, markerboard displays, or even markerboard craft tables.

Art classrooms can benefit from markerboard plywood construction, but this material can also be used in more formal settings, like an office meeting room. Since the writing surface is designed for use with dry erase markers, the user can draw or write directly on the plywood, then simply wipe it away afterward.

Overlaid Plywood

Overlaid plywood is a decorative material that is often used in furniture making, fine woodworking, and finishing projects. The material is constructed in much the same way as other plywood types, using several layers of thin veneers that have been glued together to create a tough, durable plywood sheet.

However, the difference between overlaid plywood and other plywood types is that it is finished with a thin ornamental veneer that enhances the aesthetic appeal of the material. Additionally, the ornamental veneer creates a water-resistance and abrasion-resistant surface that increases the durability of the plywood.

Ply Layers

A ply refers to a layer of veneer, which is used with at least two additional layers to create plywood. Typically, plywood has an odd number of plies, starting with three and increasing from that point.

3-ply is a common plywood option that is usually used for indoor projects. This type of plywood tends to look more decorative and may only be a few millimeters thick.

5-ply is a step up from 3-ply in both durability and strength. It can be used indoors or outdoors for light construction, but is not typically strong enough for use in framing permanent structures.

Multi-ply is the final category for ply layers. It encompasses any type of plywood with seven or more plies. This type of plywood is ideal for roofing, framing, and other exterior structural jobs.

Plywood Grades

Generally, plywood comes in four grades, ranging from A to D, though there may also be some material that has two-letter classifications, like BC. This refers to a material that is a mix of two types of plywood, like having one side graded B, while the other side is graded C.

A-grade plywood is the most expensive options because it has a smooth, sanded finish that doesn't have any knots or defects. This makes A-grade plywood the best choice for furniture and cabinetry.

B-grade plywood has a similarly smooth, sanded surface as A-grade, but it isn't as flawless. This means that the wood may have small defects, up to about an inch in length.

C-grade plywood is an unsanded option that can have small knots, slight discoloration, and several minor defects that may need to be repaired or covered.

D-grade plywood is the least finished option and also the most affordable. It's an unsanded type of plywood that can have several defects, widespread discoloration, and larger knot holes. Use D-grade plywood for unseen locations, like subflooring.

Plywood Ratings

There are five key ratings for plywood, including exterior, exposure 1, exposure 2, interior, and structural 1.

Exterior essentially means that the plywood can be used for exterior building projects because the plywood panels have been waterproofed and made to withstand inclement weather for long-term use.

Exposure 1 is a step down from exterior in terms of weather resistance. While exposure 1 plywood panels have still been waterproofed, they are not suitable for long-term exposure.

Exposure 2 plywood is water-resistant, but isn't fully waterproof. This means that these panels can resist a small amount of moisture, but are generally made for interior use.

Interior indicates that the plywood is not made with waterproof or water-resistant materials. Plywood with an interior rating should only be used for interior construction jobs.

Structural 1 is the rating given to durable plywood that is made to be earthquake resistant. Other types of plywood panels should not be used for seismic retrofitting projects.

Frequently Asked Questions

Which type of plywood is best?

The best type of plywood varies based on the type of project. For instance, birch hardwood plywood is ideal for furniture making or building children's toys, while marine plywood has the high level of water resistance required for porches, decking, or outdoor furniture.

Which plywood grade would look best?

The best plywood grade tends to depend on the desired look. D-grade plywood is typically considered the worst for aesthetic uses, but it's an affordable material that is suitable for unseen subflooring. If you are looking for the grade with the least defects, then A-grade plywood would look best.

Read Next: 10 Types of Insulation Every Homeowner Should Know

Read the original article on The Spruce.