Boathouse Sports CEO on Making Philadelphia Apparel Production Work

Made in America has been going out of fashion for decades as production migrated overseas, but Boathouse Sports is the increasingly rare case of a company that kept up a commitment to U.S. production.

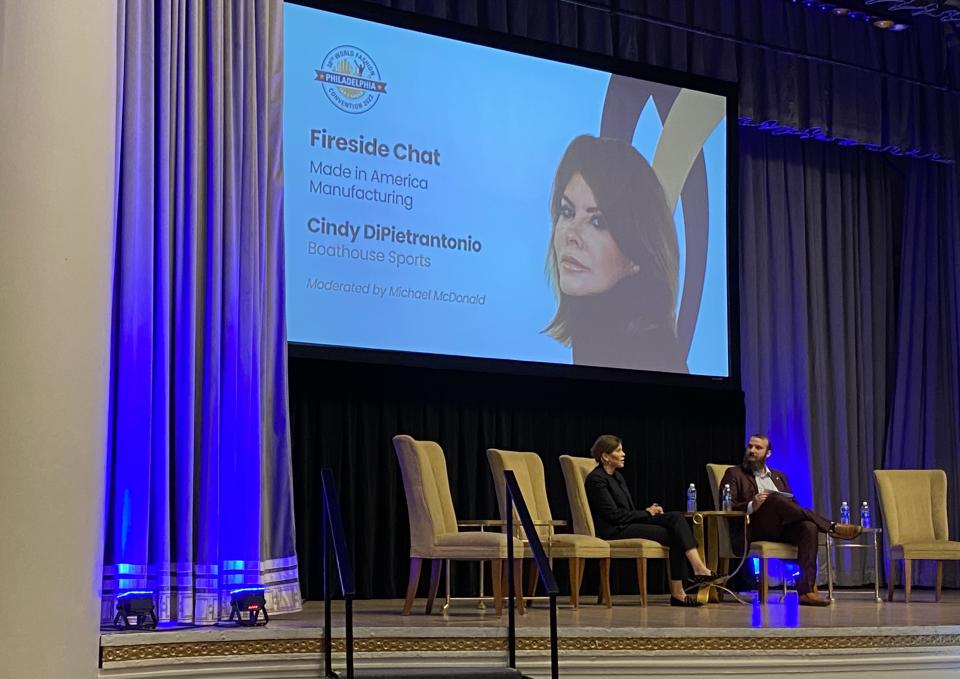

During the 38th World Fashion Convention on Monday presented by the International Apparel Federation (IAF) and the Sewn Products Equipment & Suppliers of the Americas (SPESA), Boathouse Sports CEO Cindy DiPietrantonio sat down with SPESA’s Michael McDonald to discuss the company’s onshoring story. Proving skeptics wrong, the Northern Philadelphia-based company has succeeded.

More from Sourcing Journal

CEO Corner: How One LA-Based Brand Helps Women Reach for the Stars

Department of Veterans Affairs Fails to Comply with Make PPE in America Act, US Textile Makers Say

Does Prison Labor Pervert What it Means to Say 'Made in the USA?'

“People say you’re crazy, because you’re never going to be able to grow this business,” she said. “So many challenges…being a U.S. manufacturer, and people said, ‘You’re not going to do this, you’re not going to get it up over the hill.’ And we did.”

Earlier in her career, DiPietrantonio was the chief operating officer at Jones Group, where she experienced the shift from domestic to overseas production firsthand. Initially during her tenure, the company made all its products in the U.S., including areas like New York, New Jersey and Tennessee, but eventually production moved away, and DiPietrantonio led the office overseeing China, Hong Kong and Taiwan.

After her time at Jones Group, DiPietrantonio worked in private equity consulting before meeting Boathouse Sports founder John Strotbeck. At that time, the pandemic had thrown a wrench in what was previously a “recession proof” business of school sports apparel, spurring it to pivot to medical gowns and masks.

Strotbeck was an Olympian athlete competing in crew, and Boathouse got its start making jackets with tails that would protect the wearer while seated. The brand gained attention around three decades ago when National Football League coaches Bill Belichick and Bill Parcells were spotted wearing the coats. When DiPietrantonio joined the company, she instituted a “plan B” for the brand that took it beyond the school and university business. First, she launched e-commerce, enabling consumers to buy jackets directly. Next up were a brick-and-mortar presence, collaborations and licensing deals.

A benefit of the brand’s U.S. production is quick turnaround times. As an example, Boathouse got a call from the New York Liberty basketball team commissioning a custom jacket to give to WNBA player Sue Bird on her retirement. With just a four-day window, Boathouse had time to not only produce the jacket but remake it to fix the sizing.

DiPietrantonio also stressed the importance of pre-competitive collaboration. Boathouse has worked with other sewing manufacturers in the Philadelphia area—one of which creates tarps for Major League Baseball and one that produces for the military. “Instead of looking at each other as competitors, we’ve looked at each other of, ‘How can we help each other?’” she said.

DiPietrantonio said one of the biggest challenges related to U.S.-based manufacturing is labor. To overcome this, Boathouse has partnered with a technical school to provide education in areas like pattern making. The company is also working with immigration to bring skilled labor to the U.S.

She also noted that manufacturing provides an alternative skilled trade career path for students who may not want to go to college. Answering an attendee’s question about how to “make sewing cool again” for younger generations that don’t want to enter the field, DiPietrantonio said that much of it comes down to exposure. “One of the ways that I am gaining success is by having people come into the facility,” she said. “You just have to come in and really envision it.”

For DiPietrantonio, manufacturing is necessary and it unlocks opportunities to support people. “We need to strengthen communities,” she said. “And I don’t just mean in the United States, but everywhere, because I’m absolutely convinced the stronger the community is, is where you’re going to affect change.”