How to Add Insulation to Walls That Are Closed

The Spruce / Jason Donnelly

Reviewed by Johnathan BrewerFact checked by Alexandra Kay

With a few exceptions due to climate, almost all newer homes have insulation. It's simply a matter of course now, as a well-insulated home can cut down on energy usage year-round. But walls of older homes built before the mid-1960's and even a bit later often will not be insulated. Uninsulated closed walls cause discomfort and high energy costs. A lack of wall insulation means an overtaxed heating or cooling system that diligently blows hot or cold air, yet with a house envelope that isn't cooperating.

In a perfect world, you would be able to magically place insulation behind the closed drywall panels and be done with it. Reality dictates that permanently attached wallboard must be hacked away; drywall screws or nails individually removed; R-13 or greater roll insulation inserted; and new drywall hung, finished, and painted.

It's a mess, time-consuming, and expensive. Is there a way to install insulation behind closed walls? Injection foam and blown-in cellulose can both be installed without removing the drywall.

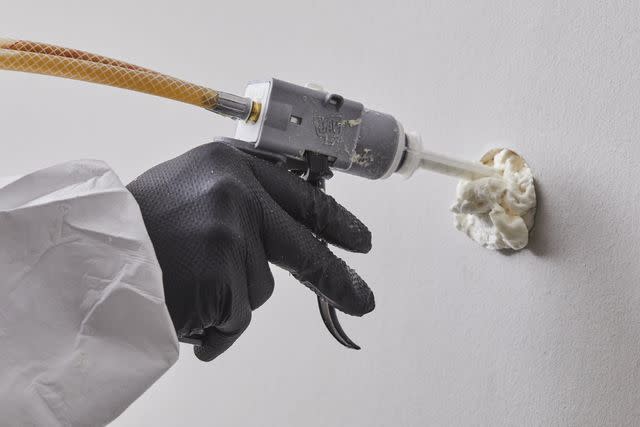

Injection Foam

Foam has advantages over fiberglass insulation, chiefly because it resists mold and mildew better than loose-fill, batt, or roll fiberglass.

What Is Injection Foam?

Injection foam is a spray form of insulation used to fill cavities of a home. It is a plastic substance.

Unlike blown-in cellulose, its strong expansion properties mean that it can force its way into difficult areas, such as around wires, boxes, protruding nails and screws, and other spaces that tend to hang up gravity-fed cellulose.

Foam injection insulation is similar to those individual cans of foam insulation you can buy at a home center but on a much larger and far more efficient scale. Professional injection foam installation is best, but a few manufacturers do offer moderately expensive do-it-yourself kits. Foam insulation is probably the best retrofit choice in terms of avoiding wall damage.

Pros

Expands to work into difficult areas that blown-in insulation may ignore

Moisture-resistant

Cons

The injection foam process creates holes in the walls that need to be filled, patched, and painted

Brands

The Spruce / Jason Donnelly

Loose-Fill Blown-In Cellulose Insulation

Loose-fill cellulose insulation begins as paper and gets turned into insulation. The key ingredient that makes this work is boric acid.

What Is Loose-Fill Blown-In Cellulose Insulation?

Loose-fill cellulose insulation is insulation that fills wall cavities, often made of recycled paper.

With boric acid added for fire resistance, shredded, recycled telephone books, tax forms, and newspapers all contribute to making safe cellulose insulation.

Blown-in cellulose is injected into the wall cavities by a series of holes drilled into either the inside or outside of the walls. Doing it yourself would require watching out for wires in studs and repairing any dry wall holes afterward.

Pros

Affordable type of insulation

Resistant to pests, mold, and mildew

Cons

Tends to settle, potentially resulting in higher energy bills

Requires a vapor barrier

Holes must be created in the walls

Brands

The Spruce / Jason Donnelly

Blow-In Blanket Insulation (BIBS)

Retrofit wall insulation is a debatable subject because there is no single right answer for all homes and homeowners. Only a cost-benefit analysis in relation to your own situation can help you arrive at the right answer.

In some cases, the cost of adding insulation may exceed the cost of energy needed to heat or cool it. While uninsulated walls are never beneficial from an eco-friendly standpoint, sometimes they can make more financial sense than if your only solution is to remove all of the drywall, insulate, install drywall, and paint again.

Still, for all of the cost and effort involved, the remove-and-reinstall method is simple, straightforward, and can give you the best assurance that all vacancies in your walls are being filled. A newer method called BIBS helps to bridge the gap between injected insulation and roll insulation.

What Is Blow-In Blanket Insulation?2

Blow-In Blanket system (BIBS) is the trademarked name for a patented new-construction method of insulating walls with blower-injected insulation that can be used for either open or closed walls.

On open walls, a fabric sheath or net is attached to studs, providing a type of cage that contains blown-in fiberglass (not cellulose) insulation, in pellets and other forms. Unlike loose-fill insulation, the insulation forms a tight, dense, seamless blanket that is highly effective at stopping air infiltration.

Pros

Does not settle. The initial volume you fill will remain at that volume

Certified BIBS materials do not soak up moisture, so mold and mildew growth is inhibited

Cons

BIBS is a fairly specialized system

BIBS is not a do-it-yourself process

Brands

Blow-In Blanket System is a patented system by Service Partners LLC, which certifies a few insulation products by different manufacturers for use with the BIBS system.

The Spruce / Jason Donnelly

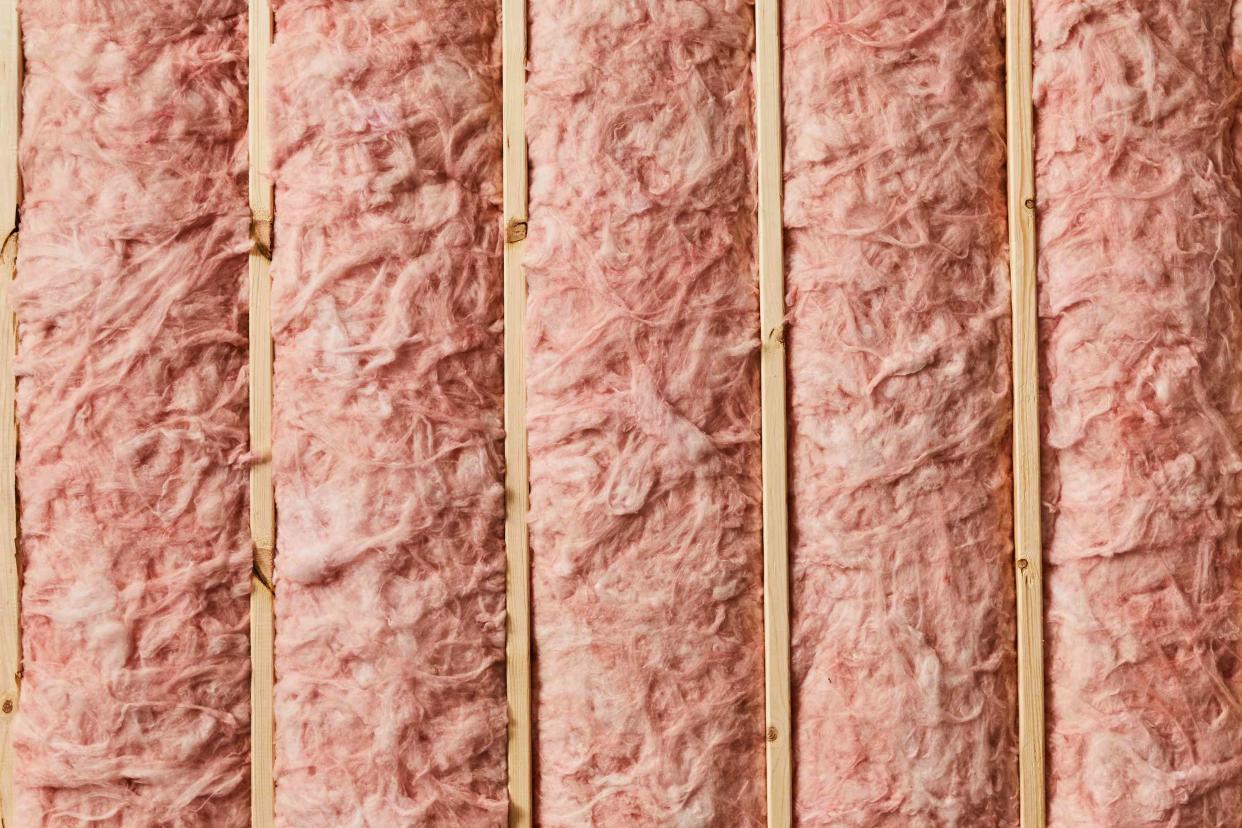

Roll Insulation

This time-tested method does have its merits, namely its lower cost.

What Is Roll Insulation?

Roll insulation is the traditional method of opening up drywall to insert fiberglass or rock wool insulation.

Pros

Ensures maximum wall cavity coverage in cavities without obstructions

Relatively low cost

Do-it-yourself project

Only simple tools are involved

Cons

Messy

Labor-intensive

Might be a health hazard if the walls are painted with lead-based paint

Brands

The Spruce / Jason Donnelly

Read the original article on The Spruce.