Tesla Gigacasting a Car’s Entire Underbody Is Surely a Great Idea

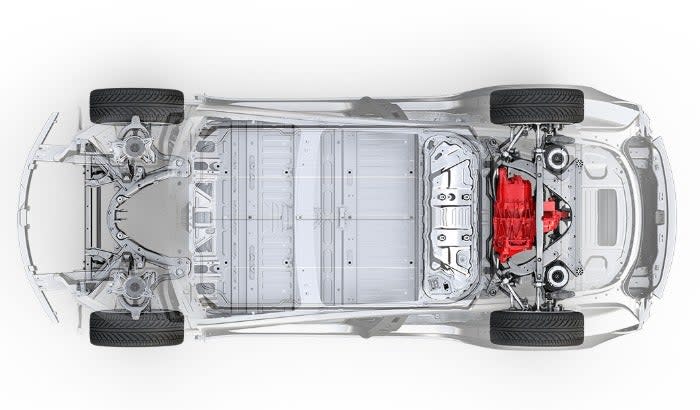

Tesla is a disruptor, like it or not. Since the start, it has approached issues in different, often Wild West, ways. Whether it's offering the first luxury EV, using everybody as a beta test for its advanced driver’s assistance systems, building cars in tents, or using wood and zip ties to finish cars, Tesla’s attitude and approach to building cars fundamentally differs from the established automakers. Now, Tesla wants to expand its troublesome Gigacast parts beyond front and rear crash structures. It wants to cast the entire EV skateboard in the same way.

Gigacast is Tesla’s method of using huge castings to make expansive sub-assemblies without the need for multiple parts. Normally, cars are produced using stamped sheets of metal bonded together with welds or structural adhesives. Automakers do this for several reasons: It’s easier to produce, easier to repair, and generally reasonably cheap to do. However, it does require a few steps in production to create stamped parts like this, which requires increased investment in manufacturing facilities.

Yahoo Autos

Yahoo Autos