Metzeler Roadtec 01 Tire Review — Dr. Moto Review

Metzeler Roadtec 01 Tire — Dr. Moto Review

Metzeler recently invited us to Germany for the world press launch of the all-new Roadtec 01 tire line. The new tire line is the successor to the previous Roadtec Z8 Interact series. The new Roadtec tire gets the fresh 01 designation because it comes with different materials, compounds, and even a new pattern.

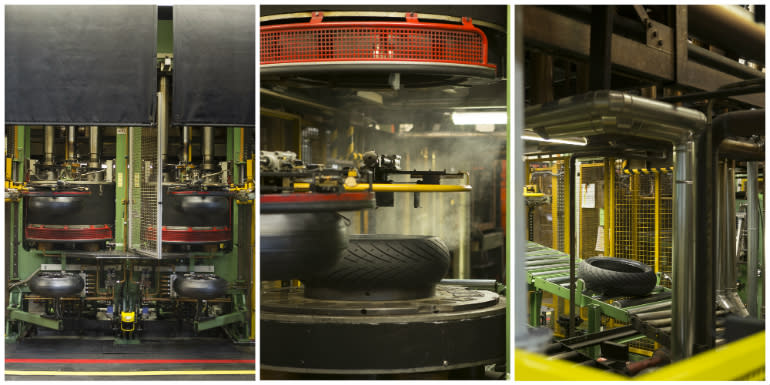

How the Rubber Gets Made

The product introduction started with a tech briefing and a tour of the factory which makes the Roadtec 01 tires. Located in Breuberg, Germany, it's highly automated and uses sophisticated industrial robots to build up the tires around the clock, seven days a week. Starting with a rubber sleeve which becomes the inner liner, the internal radial wires are then spooled into place. Another robot takes over for the step where the rubber is applied. It comes in long strings that look like black snakes, extruded like tooth paste onto the tire carcass as it is slowly turned. Different rubber blends are used for the shoulders and tread centers; the raw carcasses covered with fresh rubber are called “green” tires.

READ MORE: Metzeler ME888 Marathon Ultra — First Ride Through Italy | RideApart

Next, the green tires are fit into a steel mold and heated to more than 300 degrees F for about 15-20 minutes (depending on size and type) during the vulcanization process. This step creates the tread pattern and all of the writing on the sidewalls, and hardens the rubber to resist wear. Tires are removed and allowed to cool slowly, then moved to storage areas for shipment.

According to Metzeler, building tires robotically minimizes variations in thickness which improves uniformity and greatly reduces unevenness and imbalance. Therefore, the tires need fewer balancing weights, mainly to counteract imbalance in the wheel and rotor assembly.

Roadtec 01 was designed to increase tread-wear mileage, while improving grip on wet and low-friction surfaces, with the goal to provide longer wear and mileage by about 10% over the prior Z8. The new Roadtec 01 was also designed to be adaptable to a wide variety of different motorcycles and riding styles. New materials, compounds, profiles and tread patterns are used. Contact patches are wider and shorter, which in conjunction with Metzeler's 0-degree steel-belt technology, is designed to provide longer wear and lasting performance, along with stability and comfort. Metzeler states that the Roadtec 01 delivers top mileage in its segment, in part due to more-uniform and regular wear.

Roadtec 01 also has a new tread pattern, with front tire grooves at steeper angles relative to the rolling direction for improved mechanical grip in slick conditions. The open tread pattern also has a high void-to-land ratio to direct water away from the contact patch.

READ MORE: 10 Common Motorcycle Accidents And How To Avoid Them | RideApart

Different rubber blends are used at both the front and rear. At the front, a 100-percent silica rubber compound is employed for extra grip while braking, particularly in slick conditions. At the back, a dual rubber compound with 100-percent silica compound on the shoulders, and a blend of carbon black and silica at the middle provides greater resistance to center wear.

Where the Rubber Meets the Road

We got to flog a wide variety of motorcycles shod with Roadtec 01 tires on roads outside of Frankfurt, Germany, and on Bosch's proving ground at Boxberg. Half the day was spent riding on the back roads through quaint old towns and villages, and rural countryside, with a short run on the highway. By switching from one motorcycle to another during stops, we were able to get a feel for how the tires work on a variety of sport touring, adventure and naked bikes.

Yahoo Autos

Yahoo Autos