Processor cooling innovation may eliminate computer fans and save billions

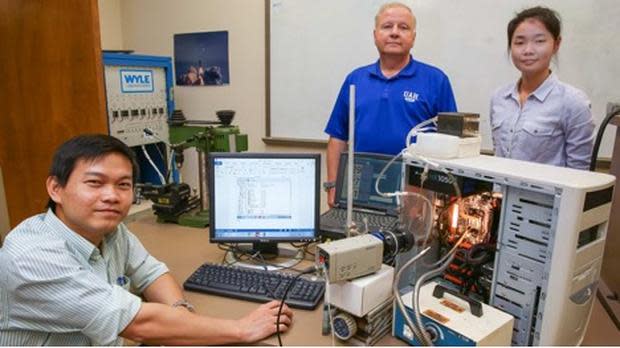

Cuong Nguyen, Dr. James E. Smith Jr., and Xiaolin Wang are members of a University of Alabama in Huntsville research team.

Image courtesy of UAH

Around this time last year, I wrote about a way to cool data-center equipment that eliminated fan noise and frigid temperatures in the white space. The trick was to immerse the equipment in 3M Novec: a non-flammable, non-corrosive, hydrofluoroether liquid with great heat-transfer characteristics.

Well, my optimism did not pan out it seems. Data centers are still noisy and cold. However, I am not giving up hope as long as there are smart people like Dr. James E. Smith Jr., Cuong Nguyen, and Xiaolin Wang, members of a University of Alabama in Huntsville (UAH) research team that devised a new way to cool computer processors using a liquid.

The UAH press release states, "A patented passive-cooling system for computer processors that's undergoing optimization at The University of Alabama in Huntsville could save U.S. consumers more than $6.3 billion per year in energy costs associated with running their computer cooling fans."

Instead of Novec, the researchers chose a different 3M product: Fluorinert Electronic Liquid FC-72, "a non-conductive, thermally and chemically stable liquid ideal for many direct contact single- and two-phase low temperature heat-transfer applications."

Passive cooling

Another interesting piece of the puzzle is that the entire system is passive -- no electricity is used to cool the processor in the test computer. Passive cooling is possible because of the excellent heat-transfer characteristics of Fluorinert FC-72. The following steps explain how the processor is cooled using FC-72.

Heat from the computer processor vaporizes the Fluorinert liquid.

The vapor being lighter moves upward to the heat exchanger.

The FC-72 transfers its heat load to the exchanger, which in turn transfers the heat to the surrounding air.

Removing heat causes the FC-72 to condense into a liquid that flows into the holding tank below the heat exchanger.

From the holding tank, the liquid FC-72 travels to the processor where the cycle is repeated.

The system has successfully cooled Intel Pentium 4 and Core i3 processors.

The passive-cooling system with the heat exchanger and holding tank on top.

Image courtesy of UAH

Passive cooling vs. fan cooling

Nguyen, a UAH graduate student, ran experiments using the test setup to accumulate data for his chemical-engineering master's thesis. He compared the passive system using FC-72 to solid-state passive cooling, where the processor has intimate contact with a high thermal-conductivity metal heat sink and the more prevalent fan-cooled systems.

This photo shows how the lines connect to the processor.

Image courtesy of UAH

Nguyen ran no-load and heavy-load 12-hour tests using all three cooling methods and compared the results. Nguyen mentioned in the press release that the FC-72 cooling method stabilized the processor temperature at an acceptable level for the entire test period.

Today's processors have an acceptable range of 50 to 90 degrees Celsius (122 to 194 degrees Fahrenheit). Nguyen's experiments showed that the FC-72 maintained a processor temperature of 56 degrees Celsius (133 degrees Fahrenheit). Nguyen then explained why a passive system is a big deal, "When we remove the cooling fan, it saves material costs, but it also eliminates the noise, vibration, and dust contamination of fan cooling."

Another advantage of passive-liquid cooling systems: they allow engineers to locate the heat exchanger away from the processor, creating space and design options.

Other potential applications

In the press release, the research team mentioned passive-liquid cooling has the potential to help other application besides cooling processors. For example, Professor Smith pointed out that cooling power transistors used in smart-grid applications would be a good candidate for passive liquid cooling, adding, "Wherever you want to make high power in a small area, that is a potential application."

Stay tuned. I hope to have an update for you next April mentioning that data centers are no longer noisy nor freezing cold.