Cambrian Genomics laser prints DNA to rewrite the physical world

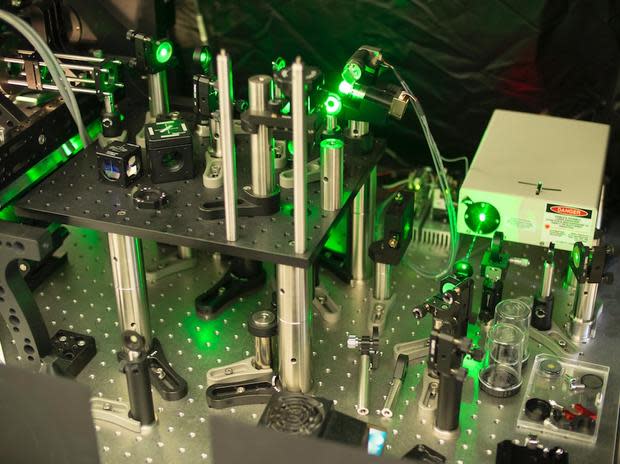

Cambrian Genomics' DNA laser printer.

Image: Cambrian Genomics

"We print life. Life is very simple, it's just code. Four letters -- we print that."

Those are the bold words of Austen Heinz. He invented a 3D laser printer that prints custom DNA sequences, and it has become the foundation of his new startup, Cambrian Genomics.

The idea behind the company is that everything is alive is simply code. The primary nucleobases -- adenine (A), cytosine (C), thymine (T), and guanine (G) -- form base pairs in a specific order to create strands of DNA. Cambrian Genomics uses proprietary technology to synthesize, sequence, recover, and assemble ACTG to create custom DNA for customers.

"Everything that's alive we want to rewrite," Heinz said. "Everything that's alive can be made better and more useful to humankind, including human cells. Plants can be made to take out much more carbon out of the atmosphere. We can make humans that are born without disease that can live much longer. We can make humans that can interface directly with computers by growing interfaces into the brain."

Antony Evans is one of the founders of the company Glowing Plant, which created glow in the dark plants by manipulating DNA. Their crowdfunding campaign raised nearly $500,000 and Glowing Plant will eventually be printing DNA for its plants using Cambrian Genomics technology. He said the DNA laser printing technology could have a bigger impact on society than the internet did.

"DNA is the most important system on the planet: it feeds us, it shelters us, it provides our energy (oil is stored life!), it even is us," Evans said. "Being able to control and manipulate living things changes, at a fundamental level, what it means to even be human. It offers us the prospect of extending life, feeding everyone, creating a sustainable planet."

Some of the technology Heinz is using has been around for a few years, but no other company has been able to utilize it in such an efficient way. The major value add for Cambrian Genomics is how cheaply it can print DNA.

Formerly, the cost of DNA was around a dollar a letter (ACTG). So, according to Heinz, it could have cost more than a car to purchase a couple of genes. If you consider each letter as a bit and each bit costing a dollar at today's prices -- humans have six billion bits, which means it would have cost $6 billion to synthesize a single human's DNA.

The cost was high because you were typically dealing with one machine that is making one strand at a time, usually with errors. Scaling was an issue. Once Heinz realized he could do many processes at the same time, he was able to cut the cost dramatically.

"The way we made DNA cheap is we stopped making it one at a time and stopped trying to fix it, so that we could make the DNA to write the same cost as to read," Heinz said. "We make DNA massively parallel in an array, and then we look at it under a microscope and see if it's good or bad. If it's good we use it, we recover it with the laser, if it's bad we don't."

After paying $100 for the array and paying for the sequencing, which is roughly $1000 for about six billion letters, you're able to reduce the cost of writing, or synthesizing, the DNA to the cost of reading the DNA which is now almost nothing. Dropping production costs that low meant a real business opportunity had arisen, but Heinz didn't set out to be in business.

When he was in undergrad, he raised $50,000 to build a lab to make custom living organisms. For example, he helped create a bacteria that was fed to mice to make the mice's insides glow at certain wavelengths so that they could be identified by their guts. He was able to perform some other experiments but the process was always slow and expensive.

The work he was doing in the lab eventually became too expensive, so he left to pursue a PhD in electrical engineering. Over the next few years, Heinz built a device that could make DNA for almost no cost.

After giving a talk at Stanford in 2011 about the technology, Heinz came across Peter Thiel, who helped plant the seed in his mind that he could commercialize the technology. He continued trying to build it as a research project, but didn't have the resources he needed. So, he left graduate school and moved to the US where he incorporated a company and built his DNA laser printer.

The process starts with the chemicals ACTG being individually flowed over an array. The array is an electro chip that has around 94,000 electrodes on it. Each electrode, when activated, creates an acid locally on top of each electrode that will remove the protective cap from the last letter in the strand. As the capped letters are flowed in, they will only bind with the unprotected strands. The chemical passes over the other electrodes that were not activated, only binding with the unprotected strands on the specific, activated electrodes.

That process is imperfect, which is why the DNA goes on to a sequencer that determines whether it is good or bad. Then, a laser causes an explosion creating a plasma on the surface of the glass, catapulting the DNA sequence into a collection plate. From there a bunch of robots combine these 100 letter blocks and to make them become 1000 to 30,000 letter strands.

That is the shipped product. It is a set of wells on a plastic plate containing a dry chemical polymer that customers add water to before they put it inside of cells.

While coding a human from scratch is a ways off, what can be written is growing exponentially. Still, there are ethical concerns due to the fact that potentially deadly diseases come from small sequences. For example, Ebola is only 18,000 base pairs and Smallpox is similar.

"You can create something that could kill millions of people pretty easily," Heinz said. "The ability to write life as easy as you write computer code is a recipe to kill everyone."

Cambrian Genomics is connected to a database where users can drag and drop genes to create their product. The problem comes when users search outside the database and download sequences for diseases such as Ebola. To counteract these potential threats, Cambrian Genomics uses a program that looks for homology between the sequences to determine what the sequence represents. Another issue, Heinz said, is that people could try to order sequences that aren't familiar.

To deal with this threat in the future Heinz said that full virtualization could be the answer. DNA would be kept in house. The team would put the DNA in cells, take pictures or videos of millions of different programs, iterating on the design with the customer in a virtual environment. Once the end product is reached, it would be evaluated for safety and quality so it can be released.

When navigating potential ethical concerns at Glowing Plant, Evans said the team uses four pillars: "Radical openness and transparency, careful product design, 'beyond compliance' testing process, and stakeholder engagement and outreach."

Cambrian Genomics is printing DNA for companies such as Roche, GlaxoSmithKline, and Thermo Fisher Scientific. Heinz said the company has over 100 different investors at this point, including, Peter Thiel, Bre Pettis from Makerbot, Bryan Johnson from Braintree, Jeff Hammerbacher from Cloudera, Carl Bass and Jeff Kowalski of Autodesk, and Dave Friedberg from Climate Corporation. They also received investments from VC firms.

While Heinz didn't mention the exact amount the company had raised, he said it's "millions and millions and millions and millions."

Heinz set out to be an academic, but he had to create a company and a business to be able to do the kind of research he wanted to do. He expected someone else would have solved the problem of DNA prices, but he is hoping Cambrian Genomics changes the concept of genetics for everyone.

"It really democratizes creation and allows anyone to be a genetic designer," Heinz said. "We want it so that anyone with a credit card will be able to make a cool creature, and I think we're pretty close to being able to make that announcement."