The iPhone travelled 500,000 miles before reaching your pocket

If you order a new iPhone today, it might already reach your home by tomorrow. It takes even less time to activate it and use it after you take it out of the box. But that iPhone traveled some 500,000 miles before reaching your doorstep and becoming the most important computer in your life.

No, your delivery company did not mess up your order. But a new report explains why and how an iPhone “travels” that much before becoming operational.

DON’T MISS: The stupidest thing Sprint has done in a long, long time

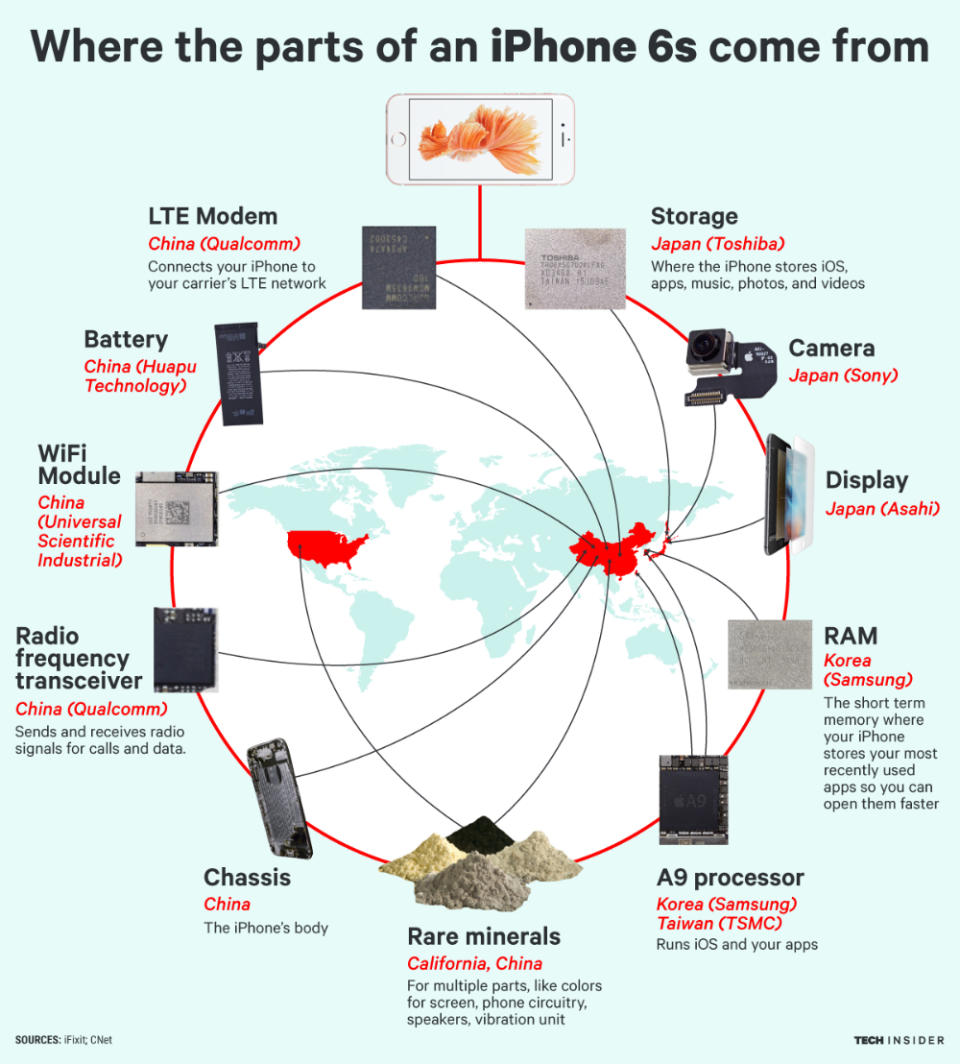

Looking at the massive logistics operations behind the iPhone, Wired concluded that the necessary parts to build an iPhone travel some half a million miles. There are many components sourced from a wide variety of part makers that are eager to become an Apple supplier – and keep Apple’s business.

According to Wired, there are at least two dozen primary suppliers of iPhone parts, based on three continents and two islands (Japan and Taiwan), that build components for the iPhone.

“The transportation complexity is magnified further because many components do not move in a simple path from supplier to final assembly,” Wired writes. “Some go on a hopscotching world tour from one country to the next and back again as one piece is joined to another to create an assembly, which is then moved elsewhere in the world for another part to be inserted or attached.”

This is how the components of the iPhone end up travelling more than 12 times around Earth before you get to power on the handset.

Looking at the home button, a critical component of the iPhone that packs a variety of functionalities, the tech site explains that the button’s journey begins in China, where the sapphire cover is made. The cover gets a metal ring cover that travels 550 miles from a different part of China, and then the resulting assembly is shipped 1,000 miles to Taiwan.

From there, the sapphire-metal combo is combined with a driver chip imported from Shanghai after a 600-mile journey. The Touch ID sensor that’s embedded in the home button came 5,000 miles all the way from Europe to meet the other components. A button switch from Japan and a springlike plastic component arrive from Japan (1,500 miles) and China (600 miles). A flex circuit is also added in Taiwan.

All these parts are then sent 1,500 miles to Japan, where a Sharp plant laser-welds them into a sealed Touch ID module. After 1,300 more miles, the assembly reaches Foxconn, where it’ll be installed on an iPhone chassis.

In total, the home button alone traveled some 12,000 miles to get to the place where the iPhone is assembled. Similarly, all other sub-assemblies of the iPhone are built before Foxconn installs them into an iPhone unit.

Wired's impressive look at this side of the iPhone business is available at the source link. Meanwhile, the following graphic from Business Insider shows where the main iPhone components come from.

Related stories

What will the Apple Car look like? Motor Trend teases that it may know the answer

Update your iPhone now or a new Wi-Fi bug could brick your phone

The 10 best paid iPhone apps on sale for free today

More from BGR: The MacBook Air might be dying, but that’s a good thing

This article was originally published on BGR.com