The end of gas-powered cars is sending this Japanese spark plug maker to the moon

If electric cars are the future—and automakers seem to increasingly think so—many things will change.

One is that we won’t need spark plugs to ignite gasoline in internal combustion engines, which seems fine to you and me, but not to a top auto-parts manufacturer like Japan’s 83-year-old NGK Spark Plugs.

In 2010, when Nissan brought its all-electric Leaf to the market, NGK Spark Plugs’ leaders realized that it was only a matter of time before their most important business would disappear, and they needed a new plan to stay viable in the era of the electric vehicle. They didn’t anticipate that would lead them to a partnership with ispace, a Japanese space company, to send a robot to the moon.

The big challenge facing widespread adoption of electric cars is manufacturing batteries that are cheap, safe, durable, frequently rechargeable, and powerful enough to keep the car moving over long range. Today, everything from airplanes to your mobile phone relies on lithium-ion batteries. Such batteries use separated electrodes suspended in a liquid solution to capture and release energy, but they have some drawbacks: They don’t hold a huge amount of power efficiently, they don’t deal well with extreme temperatures, and when things go wrong, they have a tendency to catch fire.

Battery makers looking for the next generation of energy storage see potential in solid-state batteries. As the name implies, these batteries get rid of the liquid solution and rely on an all-solid construction, as Quartz’s Akshat Rathi explains:

First, such a battery would eliminate the use of liquid electrolytes and separators, which tend to be the most flammable components of today’s lithium-ion batteries. Second, solid electrolytes, in theory, can perform the dual job of an electrolyte and a separator. Thus, the space used by separators can instead be used by more energy-dense materials. Finally, the elimination of a liquid electrolyte allows battery designers to use lithium-metal anodes, which is the most energy-dense, anode material that a lithium-ion battery can use. The combination could create a battery that’s double the energy density of today’s battery, a lot safer, and potentially cheaper.

The challenge facing chemists developing solid-state batteries is to find solid materials that electrical charges can travel through as easily as they do with the liquid solution. So far, no one has found a material that performs well and is cheap enough to bring to market.

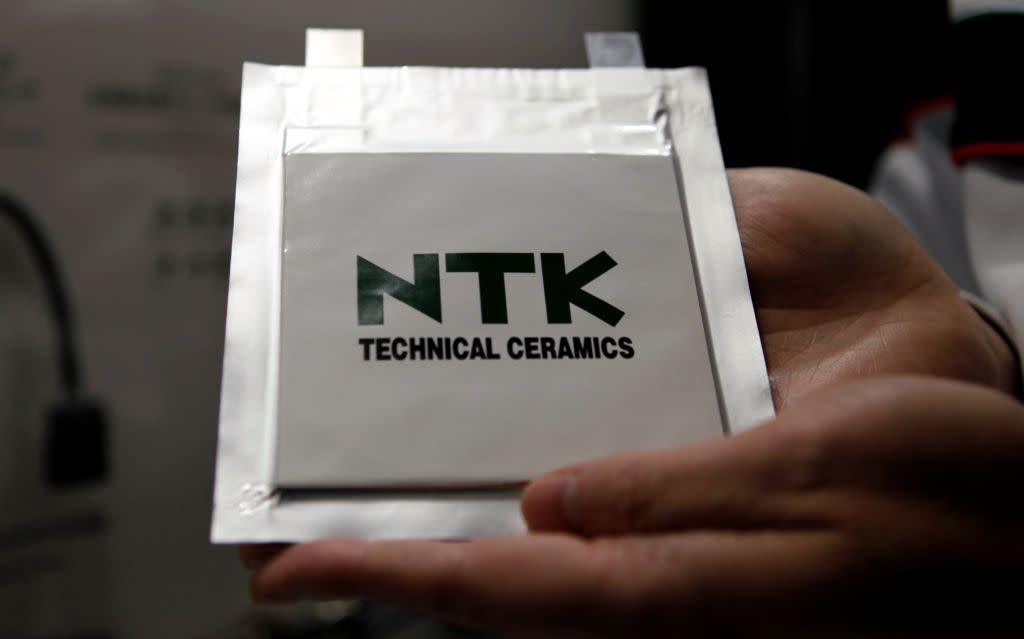

One option researchers are considering for this job are ceramic oxides. NGK Spark Plugs’ key competitive advantage has been manufacturing the ultra-thin ceramic insulator that surrounds spark plugs. Engineers at the company realized this expertise could be applied to the new way of moving cars around, and began a research program to develop solid-state batteries with their ceramic techniques.

The researchers Quartz spoke to, led by Jun Otsuka, say they are still working to develop a design that can handle multiple cycles of charging and use, a key problem with solid-state batteries. But he argues that their ceramic oxide approach is unique because it doesn’t use sulfides, which can potentially emit dangerous gasses, and because it is assembled without the use of sintering, a technique that uses heat and compression to form ceramics. Without sintering, the team believes they can make much larger batteries. But the proof of their ideas will be when they deliver a working product.

The engineers hope to have a solid-state design that is as capable as existing batteries in the next year or two. But they will still be expensive and likely reserved for specific applications where the properties of solid-state batteries matter most—and one of those is in space, where vehicles experience a huge range of temperatures, from extremely hot to extremely cold as they move in and out of sunlight. Existing space probes use thermal control systems to protect their lithium-ion batteries. A solid-state battery that offered extra power and didn’t require the extra weight of components to regulate its temperature would be attractive to spacecraft designers.

Last week, NGK Spark Plugs announced plans to send one of its batteries to the lunar surface on a lander developed by ispace, a Japanese spacecraft company that had been a competitor in the now-cancelled Lunar X-Prize. Today, backed by private investment interested in the future of the lunar economy (paywall), ispace is planning two missions to the moon under the moniker Hakuto-R—an orbiter expected to launch in 2020, followed by a lander in 2021.

On the lunar surface, temperatures can range from -280°F (-173°C) at night to 260°F (127°C) in the daytime. NGK Spark Plugs’ hope is that the battery will prove its ability to perform in an incredibly extreme environment, and help the company stand out in a market crowded with rivals trying to solve the energy-storage problem.

NGK Spark Plugs has also worked on rockets flown by the Japan Aerospace Exploration Agency and a huge energy storage project in the Arabian desert. The moon is apparently a natural next step.

Sign up for the Quartz Daily Brief, our free daily newsletter with the world’s most important and interesting news.

More stories from Quartz: