This cheap, widely available element could be the key to affordable electric cars

I-ron, not so far away.

A future where electric cars are cheaper, safer and more sustainable is coming — and affordable, easily obtained iron is the key, scientists say.

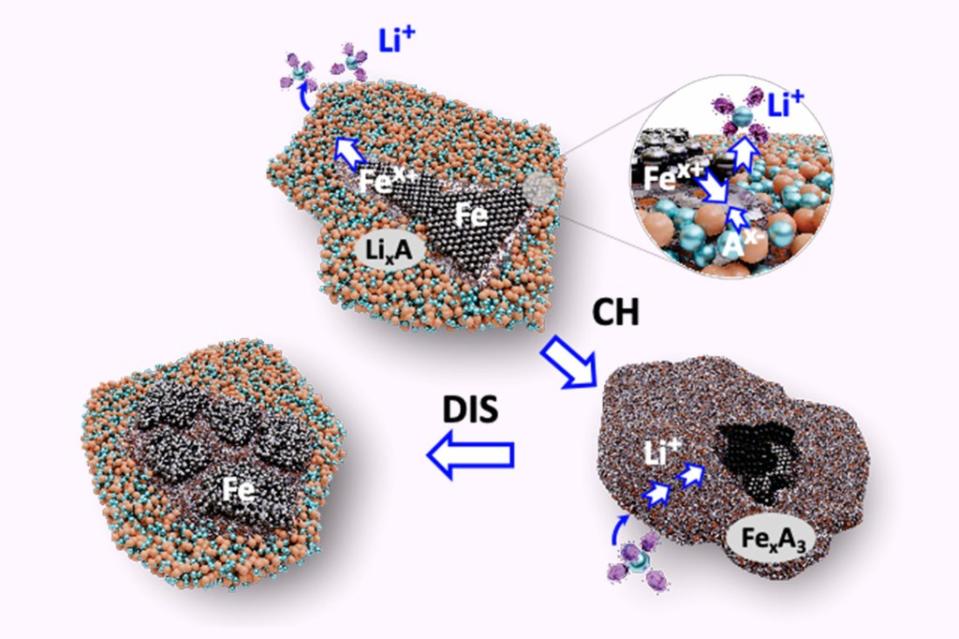

A team of researchers hopes to ignite the next green revolution by demonstrating that the extremely ordinary element — rather than rare, expensive cobalt and nickel — can be used to construct the cathode in lithium-ion batteries.

Study findings recently published in the journal Science Advances give insight into the promising project.

“We’ve transformed the reactivity of iron metal, the cheapest metal commodity, said study leader Professor Xiulei “David” Ji of Oregon State University.

“Our electrode can offer a higher energy density than the state-of-the-art cathode materials in electric vehicles,” he said.

“And since we use iron, whose cost can be less than a dollar per kilo – a small fraction of nickel and cobalt, which are indispensable in current high-energy lithium-ion batteries – the cost of our batteries is potentially much lower,” he continued.

Currently, the cathode eats up about half of the cost of constructing a lithium-ion battery cell, Professor Ji explained.

In addition, iron-based cathodes would not only be significantly cheaper, they would be safer and more sustainable.

Global hunger for nickel and cobalt has skyrocketed as electric vehicles become commonplace. Within a couple of decades, Ji said, shortages could bring battery production to a near halt.

Iron stores, on the other hand, are almost unlimited — it’s the most common element on the planet as measured by mass.

Professor Ji and the study team, from several different schools and laboratories, found a complex method to bring the iron-based cathode to full function.

Batteries would only need to have the new, cheaper cathode switched in, he said.

“To put this new cathode in applications, one needs to change nothing else — no new anodes, no new production lines, no new design of the battery. We are just replacing one thing, the cathode,” he said.

Some improvements need to be made, Ji revealed, including storage efficiency — currently, the adapted battery doesn’t seem to deliver back the total amount of electricity it takes in during a charge, for example.

Once that’s fixed, he said, it should be all systems go.

“If there is investment in this technology, it shouldn’t take long for it to be commercially available,” he said.

“We need the visionaries of the industry to allocate resources to this emerging field,” he pleaded.

“The world can have a cathode industry based on a metal that’s almost free compared to cobalt and nickel,” Ji promised.

“And while you have to work really hard to recycle cobalt and nickel, you don’t even have to recycle iron – it just turns into rust if you let it go.”