Cooking (and Shrinking) the Modern Combat Ration

The entrance to the U.S. Army Natick Soldier Systems Center is busy and confusing. Based on how much the soldier at the gate my Uber driver and I pulled up to was shouting at us, we were not doing a great job of navigating that entrance. But after a few phone calls and with the help of our escort for the day, I was finally on my way down the long path to the correct building.

Natick is an Army base where the military scientists at the forefront of the development of food systems for all of the armed forces (as well as NASA!) are developing new technologies like sonic agglomeration, vacuum microwave drying, and sonic swab technology. The part of Natick I wanted to visit is a warehouse full of super-cool machines that will potentially help our soldiers be able to do their jobs better, by feeding them foods that are packed with calories, nutrients, and flavor, but without weighing a ton or taking up much space.

And they’re doing all of this while maintaining vitamin integrity so that soldiers and even astronauts can eat that food, be full, and also be healthy. As a chef, I spend all of my time trying to make food delicious, comforting, and entertaining, while keeping the process simple enough for my cooks to be able to complete orders in a timely fashion. I wanted to find out how the scientists and engineers at Natick do all of those things, only with an added priority: making the food last for three years without refrigeration.

I was led into a large open room full of machinery and equipment that looks intense, but on closer inspection is a lot like regular, though super-large, kitchen equipment. And it smelled good in there. Like they were baking cinnamon buns and casseroles and... Anyway, let’s talk about science!

Much of my day was spent learning about the Close Combat Assault Ration. Soldiers have always needed portable rations because, well, humans eat food, and they’re not always camped out at a base with a mess tent and a cook. Those rations need to be nonperishable, lightweight, and small enough that a soldier can carry enough food for a mission that could last several days. But no matter how small and light field rations get, they can always be smaller and lighter.

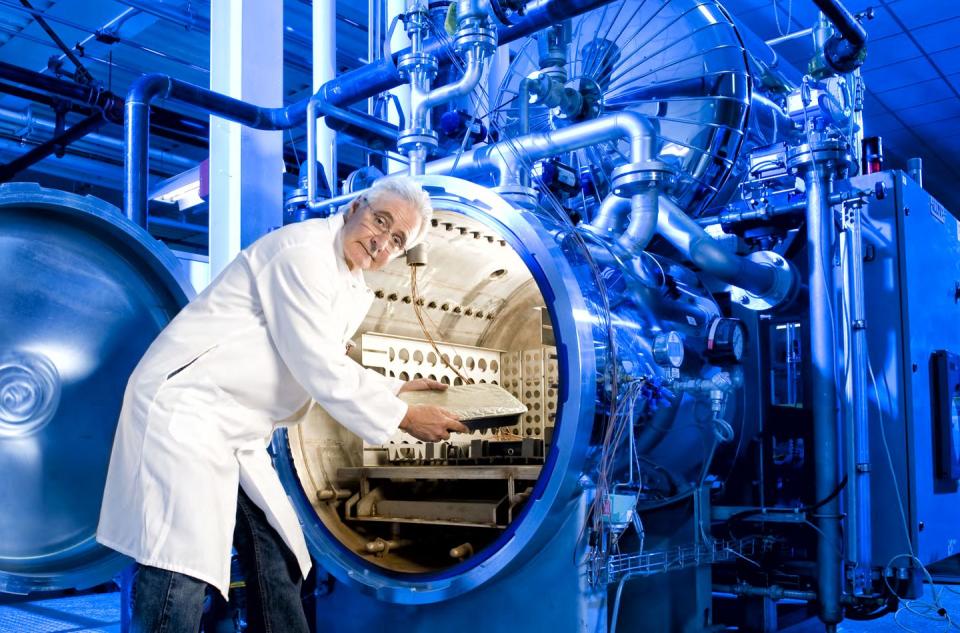

Freeze-drying technology, which has been used in large-scale production since 1940, was once the common process for reducing the weight of meals. But now, as senior food technologist Dr. Tom Yang shows me, vacuum-microwave drying has supplemented it, further reducing the weight of rations.

Here’s how it works.

Take a banana: It’s placed into a rotating drum or on a tray, which is then placed inside a large washing machine–like rig outfitted with a powerful pump that creates a vacuum, which lowers the boiling point of water inside of the machine to a mere 68 degrees Fahrenheit. (Water normally boils at 212 degrees Fahrenheit.) The banana can now be microwaved at the temperature of a pleasant spring day.

After an hour of gentle tumbling, about half of the water has been vaporized. The banana now weighs about half as much as it did when it started, but it still tastes like a banana. By virtue of the way that the banana is dried, it’s more pliable than a freeze-dried banana. So you can compress it into a dense, chewy, and tiny banana (or cheeseburger or slice of New York–style cheesecake). It can be eaten as is or rehydrated with water.

But it can still get smaller. Senior food engineer Ann Barrett, PhD., showed me a technique called sonic agglomeration. After a food has been dried in the VMD, it’s placed in an “ultrasonic welder,” where it is pressed into a small mold that has a diameter a little bit larger than a golf ball. Through a combination of pressure and sonic vibration, the food particles’ edges begin to weld, causing all of the various particles of whatever ingredients were put in the mold to fuse together.

You’re left with a tiny, dense disc of food that fits easily in the palm of your hand, but also contains hundreds of calories. A soldier can now eat it on the go or rehydrate it to make something like a paste or soup.

The whole process takes about an hour. Freeze-drying may have taken two days.

The Natick crew has been experimenting with different ways to encapsulate nutrients in the discs for longevity. They’ve had the best results by encapsulating the vitamins in fat for placement in lower-fat foods and encapsulating them in starch for higher-fat foods.

And while this is useful in military circumstances, the real benefit will be to astronauts. In extremely long missions to space, traditionally dried and packaged foods may not be able to maintain much vitamin content because of cosmic radiation and the passage of time. Current Natick tests show significant vitamin integrity—for as long as five years, which is plenty of time to get people to Mars. Without scurvy.

Next I got to see something called a sonic swab, essentially an electric toothbrush with a fancy Q-tip on the end. That Q-tip agitates the surface of a food preparation area—or say, a machine in a factory—getting at any bacteria hidden in microscopic crevices.

With the exception of the guard who yelled at me, the people at Natick are improving lives. They’re trying to give our military food that lasts and takes up minimal space, and that’s hard enough. To make it delicious is nearly impossible.

As a final test, I took a few of the Natick meals home with me. One night, I ate a Natick-made pepperoni pizza with my daughter while watching Moana. And while it was objectively not that great (the pizza, that is; Moana is amazing), it was really not that bad. If you toast it, it’s almost good!

But this food is for soldiers. Not for a New York City chef with regular access to caviar, lobsters, and the best pizza in the world. In the middle of a mission, these MREs could save lives, or remind the enlisted men and women eating them of what home tastes like. That’s all much more important than what I think of vacuum-microwaved cheesecake.

(Incidentally, it was pretty delicious.)

This article appeared in the July/August 2019 issue of Popular Mechanics. You can subscribe here.

('You Might Also Like',)