A family-owned Modesto dairy farm makes cheese from its own cows. See how it’s made

Inside Look is a Modesto Bee series where we take readers behind the scenes at restaurants, new businesses, local landmarks and news stories.

Fiscalini Farmstead, located on Kiernan Avenue outside of Modesto, has gone through a lot of changes over the 110 years it’s been around.

However, to help retain the essence of the past, the family has turned to the tradition of farmsteading — making a variety of cheeses straight from the milk produced on the farm.

Cheese production, which started at Fiscalini in 2000, is a great source of pride for the fourth-generation owners Brian Fiscalini and his sister, Laura Genasci.

“We own the cheese company together and then we kind of look at ourselves as three types of businesses: the dairy, the cheese plant and then we have a sustainability project as well,” said Genasci. “So that’s also very important to us.”

Genasci allowed the Modesto Bee an inside look at its cheese factory, which just produced its newest flavor, Balsamic Onion.

The factory is separated by rooms — each with its own function, temperature, humidity and funk.

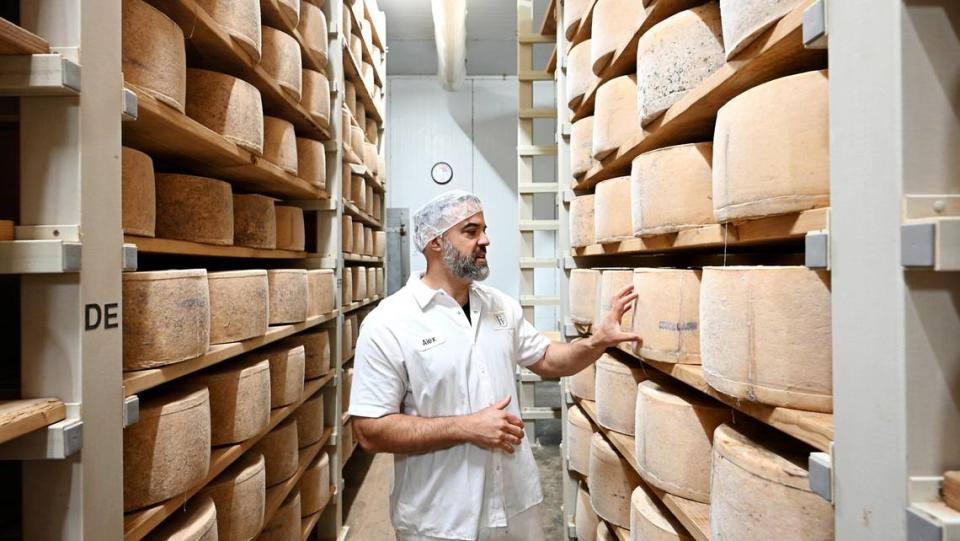

Head Cheesemaker Alex Borgo donned the necessary smock, hairnet and booties to enter the building. He explained that he, like the Fiscalinis, is also a fourth-generation dairy producer. Originally working for his own family’s cheese company in Toronto, Canada, Borgo moved to California in 2007.

“They became corporate, but I wanted to get back to like the family-style of cheesemaking,” said Borgo. “The Fiscalinis reached out to me... so I moved here five and a half years ago and joined them. Also, I was kind of sick of the snow in Canada.”

Borgo explained how milk from about 100 yards away is processed into award-winning cheese that can be found on the shelves of local grocery stores in Modesto.

First, about 3,000 gallons of milk are brought in to be pasteurized. Or, sometimes, it is not. Some of Fiscalini’s cheeses are made from raw milk, which requires a different aging process.

The milk then sits in a high-humidity room inside of vats, which are agitated. Once the pH levels are at the perfect level, the whey (the liquid) is separated from the curds (the solid).

The curds are then formed into stacks and placed on top of each other so that extra whey will be drained out by gravity. Spare whey is then redistributed to the feed given to its cows.

Next, the curd blocks can be flavored. This is where Fiscalini’s habanero, truffle, craft beer and purple moon — the latter being a wine-infused variation — begin to develop their signature tastes. Almost all of Fiscalini’s cheeses are cheddar or a variation thereof. The company’s newest flavor, balsamic onion, is the first new flavor they’ve developed in four years. The last being its truffle cheddar.

Once flavored, they’re pressed into 60-pound wheels which are aged anywhere between 60 days and 14 months. Cheese made from pasteurized milk is federally required to be aged 60 days. However, Fiscalini’s raw milk cheeses are aged up to 14 months.

After aging, the cheese is sliced and then packaged. The farm now uses something called a Form Fill Seal Machine. The process is in its name.

“Not even a couple of years ago, we were doing everything by hand. We were putting each piece into a bag, then sealing each bag, and labeling it by hand,” said Borgo. “We went from like eight pieces per minute to ‘can’t go fast enough.’” The machine can package 80 pieces per minute. Once packaged, the cheese is shipped to its customers, including local grocery stores.

Farm to table and a changing industry

Fiscalini sat in a chair in his office and watched over a set of computer screens that monitored the dairy’s robotic milkers. On the screens were boxes, each providing data from the machines.

“Each one of those little boxes represents one robot, so there’s 20 boxes there,” said Fiscalini. “Of course, like everything else today, there is an app that we can use to also monitor individual cows, robots, all of the (key performance indicators) or all of the pertinent information that we need to make decisions.”

The grounds were first used for dairy in 1914. It now sits on the precipice of its past, the traditions and methods of generations. What used to be done by farmhands can now be done with robotic automation and software. Cow management, once also done by farmhands, is now done through an app.

Methane produced by the farm’s manure is now digested and converted to electricity to offset electrical costs on the farm and help reduce its carbon footprint. The farm that started over a century ago is now a certified 21st-century facility.

In the previous method of milking, two groups of 27 cows would be taken into a milking parlor to be manually prepared and have milking machines physically attached to their udders by employees.

With its new automated system, it can now milk groups of anywhere from 120 to 240 of its approximately 1,200 milking-ready cows. This is done on the animals’ own accord. Motivated by feed, the cows patiently wait in line for a machine to be sanitized, coupled to their udders and then milk them. This happens 24 hours a day, according to Fiscalini.

Each cow used to be milked exactly three times a day. Now some cows get milked five times a day and others get milked twice a day. It’s up to the cows to decide how much they want to be milked.

“We’re on her schedule now,” said Fiscalini

“It’s pretty remarkable. I mean, I would love to be able to interview my great-grandfather and my grandfather... and just hear what they would think of today’s dairy farm,” said Fiscalini. “I mean, they were milking cows by hand, this is only a couple of generations ago. And now we’re turning the cow poop into vehicle fuel. I don’t think either one of those men would have ever thought that that was something we were capable of.”

The farm-to-table approach is something Fiscalini hopes to preserve, particularly in an age where the dairy industry faces mergers, acquisitions and ever-evolving technology. Currently, 20% of milk produced by Fiscalini’s cows is used for cheese, the other 80% is sold to Nestle’s condensed milk plant in Modesto.

Fiscalini said he worries about the food system in the United States, particularly American production of “commodity cheap food,” adding that it was a “much better story” when someone goes to a local grocery store and can buy locally made food.

“Sure, it’s not easy. We do not have huge economies of scale, because we are a small family business,” said Fiscalini. “But, we’re going to stay true to our values and if that means that sometime in the future we’re not able to compete, I’d rather not be in business than not stay committed to our values.”