Faba beans used to make plant-based wrap that also keeps food fresh for longer

A new plant-based film made from faba beans has the potential to keep meat and food fresher and replace plastic wrap, according to researchers at the University of Saskatchewan.

As almost all packaging has some type of plastic involved, researchers are looking for ways to reduce the amount of petroleum-based waste going into landfills.

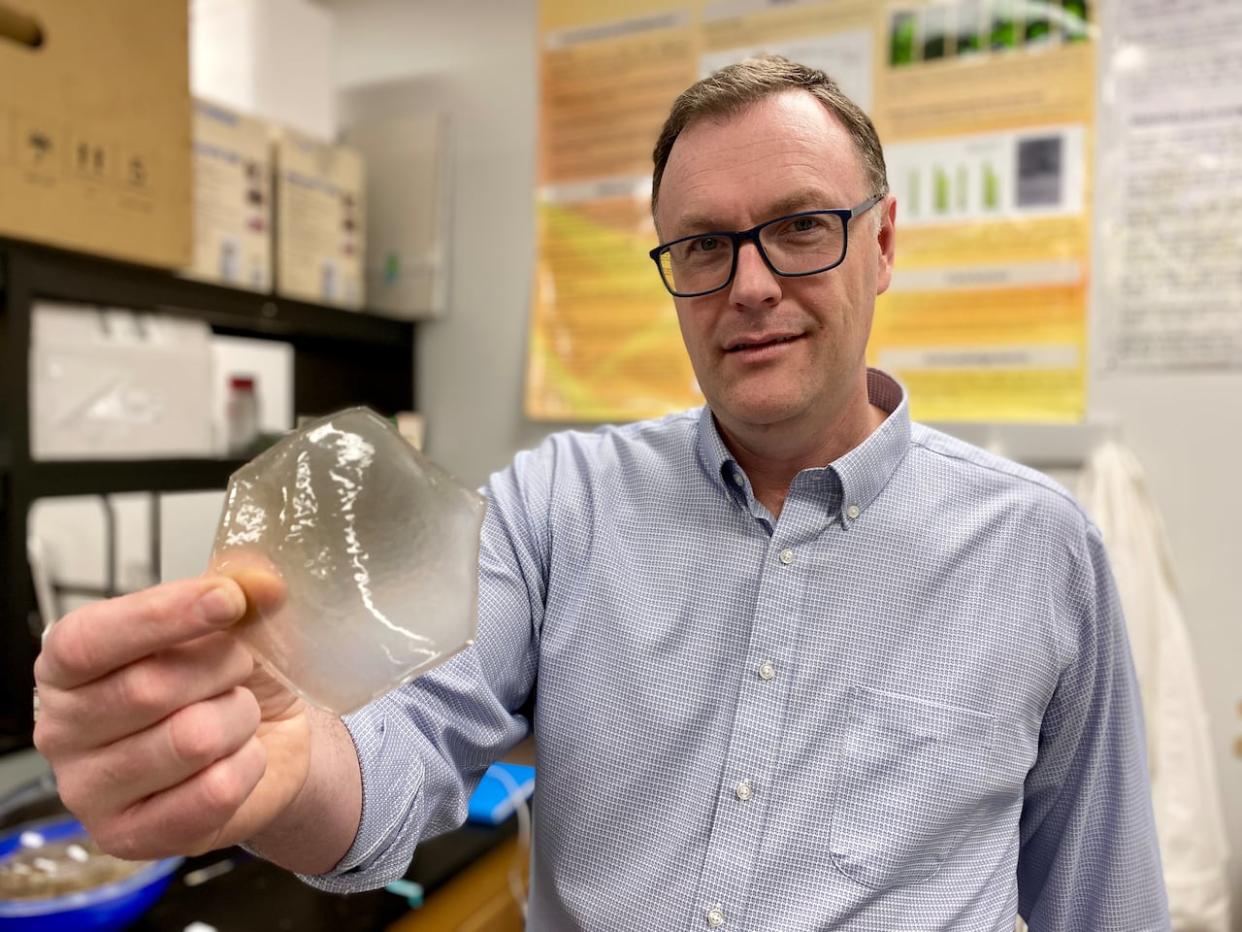

Michael Nickerson, Saskatchewan Agriculture and Food Research Chair in Protein Quality and Utilization, is heading the research team at the U of S that is creating the biodegradable film.

He said the film they created was made using faba bean protein and other food-based ingredients to make it safe for the environment.

"You could actually take this package and throw it in your garden. It'll degrade really fast. You can throw it in the compost in your green bin and it'll go in the landfill and it'll actually degrade," Nickerson said.

He said once it degrades into the soil, it will add more proteins and nutrients back into the soil because it's made from plants.

Nickerson said he's using special ingredients that make the film more functional than plastic wrap, including antimicrobial agents that prevent spoilage of meat products.

WATCH | U of S researchers creating biodegradable, plant-based wrapping for food:

While the first goal is to meet application needs, Nickerson said he and and his team are working to formulate films with different shelf lives.

"We're looking at partnering with potentially a packaging company to see how we can take it from our bench-top formulation to something that we can scale to actually hit the masses for the meat industry," he said.

Nickerson said his team is in the testing phase and they're doing shelf-life studies to show the efficacy of the films. He hopes to be able to scale it to larger structures through mass production and make it available as a roll of wrapping film, in grocery stores and homes.

Joanne Fedyk, executive director of the Saskatchewan Waste Reduction Council, said she's interested in seeing where this technology goes.

She said that plastic wraps are difficult to manage — they catch on things, get tangled and fly away — and landfills have to build fences to keep plastic bags and wrap in place.

"It's just difficult to capture because a good thing is that they're not very big, but a bad thing is that they're not very big," she said.

Fedyk said developing technology that can make meat and food last longer is important, as food waste is a major issue.

"Any time you can decrease food waste, that has a huge impact on everything," she said.