How 2 Brothers Reinvented the Cast Iron Skillet

Design is the art of evolution: Why stop at what works when you can make it better, smarter, and more beautiful? But a certain few designs don't beg to be updated the way, say, a car does. The humble cast iron skillet is one of these—you don't have to pay very much for one to get a tool that will work hard, look good doing it, and last a very, very long time.

But if designers stopped at "good enough," we wouldn't have iPhones or non-poisonous thermometers or invisible seam underpants. Enter: brothers Stephen and Chris Muscarella, founders of the Field Company, who set out to reinvent the cast iron skillet to be even better than its best self—and did it. "It's one of a few objects that you will have forever," Chris says in their Kickstarter video (psst, there are only 12 days left in their campaign!), so better make it a good one.

Why—and more importantly, how—did Stephen and Chris go about fixing up this design that feels, on the surface level, unbroken? Here's how to re-invent a classic, the Field Skillet way.

1. Identify what's gone wrong.

"A $20 cast iron skillet is a great tool and value at that price," Chris says about the bulky, mass-produced versions you can buy in Whole Foods or your local hardware store, "but it isn’t the best one that could be made." On the flip side, vintage cast iron skillets are a beautiful thing: Besides having patina, they're also lighter and smoother than newer models. But when did quality start dropping, and why?

Now-shuttered brands like Griswold and Wagner—and many smaller companies like Piqua, Favorite, Burmingham Stove and Range, and Vollrath—made excellent, hand-hewn cast iron skillets as recently as the 1940's, Chris explained. (Wagner actually got its start making swords in the Civil War, after which they had to find something for all their skilled employees to manufacture.) "They made beautiful stuff with a lot of soul that was a mix of industrial process and a lot of hand labor—things like grinding and polishing," Chris says.

But as the cost of that hand labor went up in the 50's, shortcuts were inevitably taken in the design process, resulting in the heavier, rougher, cheaper pans that we see more of today.

2. Try to get back to the good old days.

Two distinguishing qualities of vintage cast iron stood out to Stephen and Chris in particular as worth getting back to: lightness (as in weight) and smoothness.

To figure out if it was possible to make a lightweight, smooth pan through modern production, they tracked down an expert metallurgist—one Dr. Marcin Gorny of Krakow, Poland—and went to visit him. "We learned a lot on that trip," Stephen recounts on their Kickstarter page, "But we also confirmed that the techniques used to make thin-walled, smooth cast iron require specific set-ups and fairly involved labor that would be extremely expensive to recreate today." In short, sticking to the way things have been done would cost a fortune.

"If you wanted to make exact replicas of vintage pans, they’d cost $100 each just to manufacture and you could only do them in very small batches," he explains, and you can only imagine what those would cost in a store. But they were determined. "We wanted to make a beautiful pan that would be the one you would reach for every day, almost like a favorite bag or piece of clothing," Chris says—and dropping the overall weight was the most critical step in that direction.

3. Come up with a workaround.

Realizing that they couldn't rely on traditional production methods, the brothers worked to reverse-engineer a solution. Instead of casting it ultra-thin—which requires hyper-specific temperature regulation, superfine-grained sand moldings, and other kinds of other metallurgical magic to make the iron flow "faster and smoother" through the mold—they came up with a way to machine the already cast pan to make it smoother and lighter in one fell swoop.

"For the level of weight we wanted, there was no way to make that happen without removing metal after the iron is cast," Chris explains. "That means that the smoothness is, in some ways, a side effect of one of our biggest criteria." Of course, you can't sand it down to nothing, since one of the most compelling cases for cooking with cast iron is because it retains heat so well (a property that's also directly proportional to its weight). As with every other step, their team tested and tested to figure out how thin they could get the cast iron without compromising its ability to reliably put a gnarly sear on a steak.

The main catch with a super-smooth surface, however, is that it's not ideal for getting seasoning to stick (one of the reasons that modern cast iron is so pebbly to the touch is because that makes it cheaper to season, and therefore slap with a flashy "pre-seasoned" label in the store). So they went to a "friend and biological chemist" named Doug to figure out how to season their super-smooth pan; let's just say that their formula is the definition of a trade secret.

The result—and it's not without pride that Stephen declares it—is that "the Field Skillet is the first smooth-surfaced pan that can hold an excellent seasoning since the early 1900s, back when they stone-ground their pans."

4. Find some people who believe in you, too.

To pull all of this off, they needed a manufacturer willing to take a leap of faith. Stephen and Chris called hundreds of foundries all over the country ("if you’re working on an American classic, it better be made in America," as Chris puts it), and time after time they got turned down. Finally, they found one outside of Chicago who was game.

"They believed in and wanted to be a part of what we were doing," Chris says. "They took a risk on us because they loved the idea of helping create a product they could take pride in." At the foundry, experts will cast the pans according to the Field Company's carefully-devised methods.

To save costs, they'll recycle all their scrap iron by melting it down for future pours; the result is a pan that's 75 to 90% recycled iron. To say the brothers are grateful for the foundry is shy of the truth: "We’re really looking forward to cooking for them with some of our first pans off the line."

5. Go big.

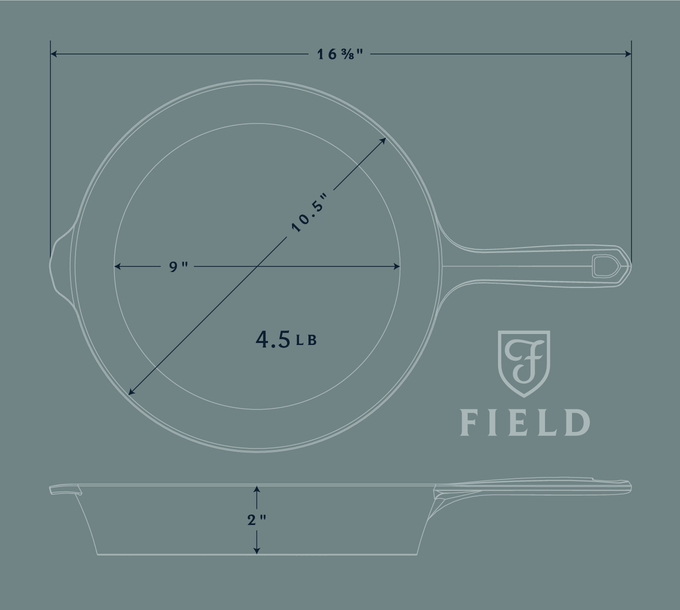

The team didn't stop at lightness and smoothness: "We put an obsessive amount of detail into the small things that you probably won't notice—but they're there," Stephen says. For starters, they went deep down one rabbit hole trying to figure out how to design a heat-proof handle on a skillet that was all one solid piece: "You can try and disperse heat by increasing the surface area of the handle with things like coils on wood burning stoves and long forked handles," Chris explains, but they "couldn’t find anything that fully solved the problem." So in the end, they focused instead on the look and feel of it: "nice curves, an elegant connection point," and so on, working through countless iterations in foam and plastic and iron before settling on the final design.

There's also a nod to the heat ring on the bottom—a well-known feature of vintage skillets—and a flat base that's supposed to be the perfect size to make the most of heat coming off a standard burner. And as for the common side pour spout, which doesn't actually keep liquids from dribbling down the pan's side, they cut it (why waste the cost?).

"To me this pan is almost 100% in the details," Stephen says in the Kickstarter video.

6. Raise cash and jump into the abyss.

"In our own kitchens, we always reached for the vintage pans," Chris points out as the root of what spawned this whole effort. Their goal with the Field Skillet, then, "was to breathe new life into a classic, because they’re our favorite kind of cookware." They've done the dirty work, and already raised nearly over $475,000 on Kickstarter (with a starting goal of $30,000!)—which means that this skillet is coming very, very soon.

In just twelve days, the Field Skillet will be fully-funded on Kickstarter, after which Stephen and Chris will start production. Pledge now to support their campaign and lock down a skillet from their first batch.