How Italian Eyewear Companies Use 3D Printing Techniques

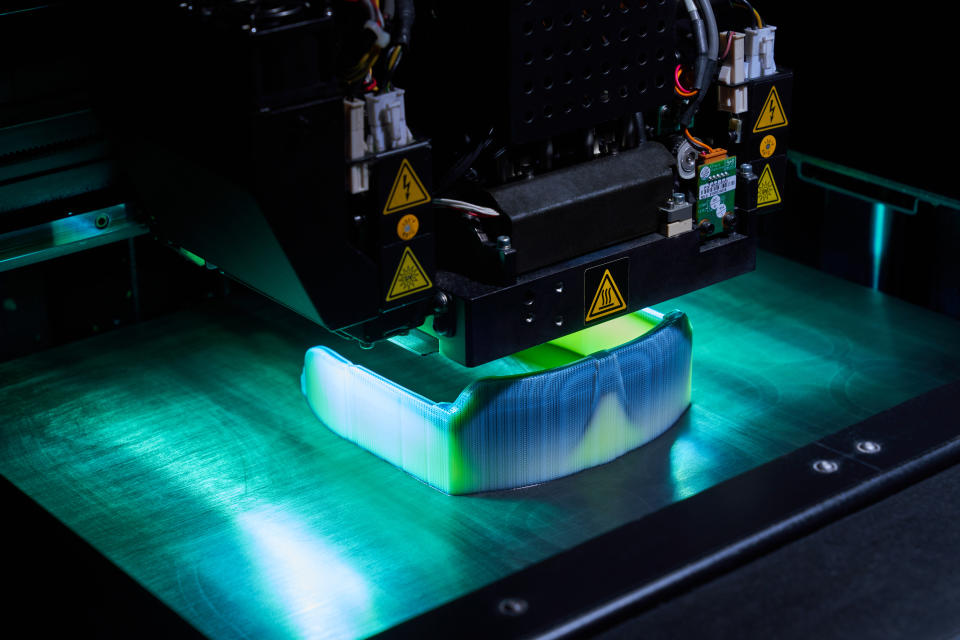

MILAN — From the mere production of prototypes, the precision and material range of 3D printing techniques have evolved to the point that they are used in industrial production, allowing manufacturers to deliver increasingly complex shapes, while being viewed as more sustainable.

Those facts are not lost on eyewear executives.

More from WWD

Carlo Roni, product development and R&D director at Thélios, said 3D printing technology is increasingly being used at the eyewear company.

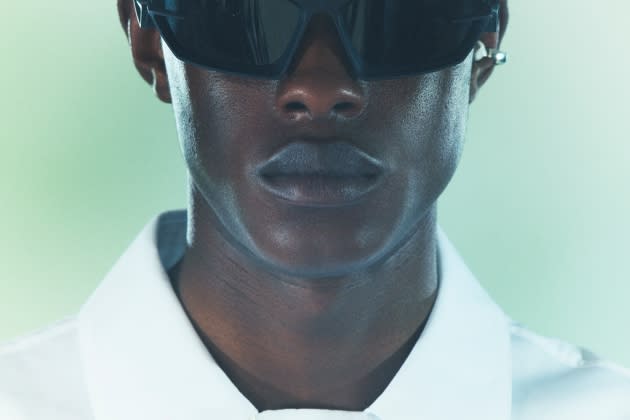

Case in point: Givenchy’s Giv Cut model, first seen on singer Rosalía at the 2022 Met Gala. This new bold unisex style is fully 3D-printed in nylon and features dramatic angles and extravagant volumes, revealing sharp “Gs” in the front and on the temples. Roni touted the success of this model and the “outstanding results” that can be achieved with 3D printing.

The 3D technique allows Thélios “to keep up with the pace of fashion rhythms and to deliver new models to the maisons very quickly to be worn at fashion shows,” Roni explained. “They also enable us to speed up the time to market of our eyewear and make it possible for some models to have the see now, buy now approach, which allows the end consumer to find the models just presented in the shop.”

Thélios is controlled by luxury conglomerate LVMH Moët Hennessy Louis Vuitton, and produces eyewear collections for brands ranging from Dior, Fendi, Celine and Loewe to Stella McCartney, Kenzo, Fred, Berluti and Rimowa, in addition to Givenchy. Led by chief executive officer Alessandro Zanardo, the Thélios plant is based in Longarone, a one-hour drive from Venice, and was inaugurated in 2018.

In fact, 3D printing also allows manufacturers to realize specific styles that could not be made with traditional moulds, respecting and reproducing the distinctive elements of the fashion brands Thélios manufactures.

3D printing also helps manufacturers anticipate technical and style evaluations on new creations, components or entire frames before they go into production, Roni continued. “For certain types of nylon frames, moreover, 3D printing can be used for products to be quickly placed on the market, especially in case of limited editions.”

“Limitations mainly concern the material that can be used in 3D printing,” Roni said. “For example, materials of excellent quality with glossy, shiny and transparent finishes are not yet available. Thélios, by vocation, fuses innovation and craftsmanship in its work, and the best results are obtained precisely when these two components are equally applied in the creation of the collections.”

Aiming to increasingly reduce the manufacturing time, time to marketing and to use materials “that are aesthetically different but at the same time of high quality, 3D printing is proving to be a strategic asset in our industry,” Roni said. “It allows us to experiment and create glasses with greater flexibility and reactivity in order to propose increasingly sophisticated and excellent models.”

EssilorLuxottica has also been investing in and experimenting with 3D printing techniques, and Matteo Battiston, global design and market research director at the giant eyewear group, said 3D printing is a manufacturing process “that over time, has turned into a technology that is completely integrated in our day-to-day activities. We employ it throughout our process, starting with design, where shape investigation, size and details can be executed in a seamless way, continuing into prototyping, where it offers an incredible acceleration in samples production and evaluation and, finally, in the final production phase, where specific techniques — especially on metal deposition — allow complicated geometries on embellishments and functional details.”

He noted that 3D-printed parts are already a standard process in the production of EssilorLuxottica’s house frame brands, including Ray-Ban, Oakley, Arnette and Vogue Eyewear, as well as the group’s luxury licensed frame brands, which range from Giorgio Armani and Ralph Lauren to Bulgari and Prada. “Our commitment to smart glasses, which we launched in 2021 with Ray-Ban Stories, accelerated our use of 3D printing techniques,” Battiston said.

The benefits of 3D techniques include extreme personalization, user-generated products, new business models and last-mile productions. “Additionally, manufacturing constraints like undercuts can be easily overcome,” Battiston continued. “In businesses with large scales of production and distribution, it is also a terrific asset when specific projects call for lower volumes and high technology.”

3D printing allows manufacturers to take a “bolder approach in the preliminary phases, being able to assess whether a crazy idea could really turn into a solid product proposition,” he said, citing Oakley Kato’s innovative freeform geometry as an example. But he noted that, “although 3D printing has revolutionized the way the industry works along the whole value chain, the overall market impact is still low, and we are continuing to explore it to from a business point of view.”

Fabio Borsoi, global research and development director for frames at EssilorLuxottica, also highlighted the sustainability advantages as 3D printing, which “minimizes material used in the product development process,” reducing the group’s overall environmental impact.

He noted that each 3D printing technique used at EssilorLuxottica plays a specific role in the company’s R&D process and in the broader eyewear industry. “There are not winners or losers, but simply more solutions to enable creativity and value for the consumer,” Borsoi contended.

Battiston said 3D printing processes “have dramatically evolved” in the past 10 years, from fused deposition modeling to selective laser sintering, direct metal laser sintering and stereolithography. “From a design and prototyping standpoint, we have been waiting for a mature development of a multimaterial and multicolor technique. Now the time is ripe, and this helps a lot also on [the] material prototyping and development side. Prototyping an acetate wet block is not a mirage anymore and designers can unleash their creativity on it. Lens 3D printing is the next frontier we are looking at.”

Borsoi added that EssilorLuxottica’s R&D team is exploring 3D printing for lenses, “but we don’t have a concrete timeline for when this technology will be delivered to the market. One benefit we see, especially with lenses, is the ability to integrate optical combiner into a more complex optical system like a lens. 3D printing has proven to be very effective with this.”

Safilo Group’s CEO Angelo Trocchia said he believes 3D technology has “great development potential both for eyewear and lenses. In addition to the technological aspect, also at an environmental level, if accompanied by the use of sustainable materials, this kind of production could surely become key. For this reason, we are working on an implementation of this technology on our models that we hope to be able to communicate soon.”

Trocchia contended that, as of today, the use of 3D printing is “still not yet mainstream in the eyewear market. At the end of 2021, Safilo launched the Smith I/O Mag Imprint 3D Goggle in the U.S., which Trocchia said was the first custom goggle built to conform to the individual features of a person’s face, thanks to 3D printing techniques.” The customization, he explained, allows to significantly increase the line of sight, in addition to the comfort.

Safilo launched the Imprint 3D Technology through its proprietary brand Smith to address the vast range of face shapes and features while eliminating the one-size fits all approach to sports gear.

Utilizing Smith’s custom app, users scan their face to capture their unique details and contours, allowing an individualized frame to be automatically generated, 3D printed — using HP’s industrial Multi Jet Fusion platform — and, finally, hand assembled.

3D printing is extensively used at Marcolin in all phases of collection development and prototyping, as it allows “to quickly verify aesthetic and technical solutions such as fitting and hinges movement,” said style and product development director Alessandro Beccarini.

He explained that 3D printing is also part of Marcolin’s ESG path — in addition to speeding up reactivity in the manufacturing process, it uses eco-friendly materials, and the technique “means producing better, faster, promptly responding to market demand, therefore generating less obsolete product.”

Last year, Marcolin launched the Adidas Sport sunglasses, with the limited-edition CMPT 3D frame that was realized thanks to the use of 3D printing in the production process. “We have created something unique that intrigued consumers, not only for the design but also for the details and the material used,” Beccarini said.

The 3D CMPT frame, launched last year, is produced with a new generation of 3D printers and has a flexible nylon structure treated with a special coating that creates a rubberized effect on the entire texture surface. The one-piece frame weighs just 20 grams and has an integrated spherical mirrored lens shield. Non-slip contact points on the nose pads and end tips give the frame an extremely comfortable fit, ensuring stability and dynamism during any type of training or competition.

Beccarini said 3D printing techniques are growing today, and that there are two main machines, one to print using plastic materials and another with metal or titanium powder.

“The printers now available on the market that use nylon and rubber allow [production of] sunglasses that are perfect to be marketed. On the other hand, for printers that use metal powders, we are still in a development phase for which there are aesthetic and technical compromises to accept,” Beccarini said.