Biotech company: We're one step closer to printing human organs

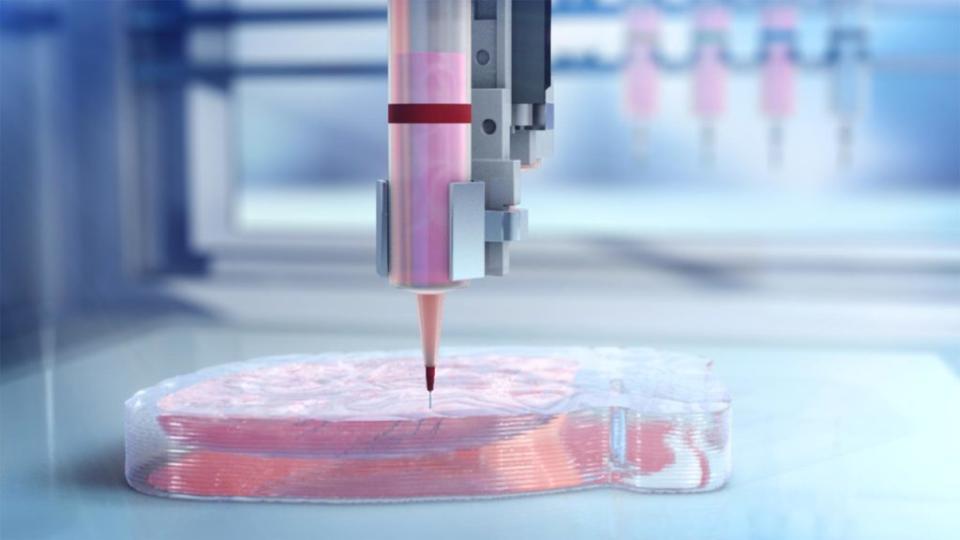

Biotech 3D printing startup BioLife4D has successfully produced human tissue in the form of a cardiac patch, the company announced on Monday, bringing it one step closer to printing organs viable for transplant.

“What’s interesting about this is that it’s being 3D bioprinted,” Joseph Woo, MD, the chair of the Department of Cardiothoracic Surgery at Stanford University, told Yahoo Finance. “Instead of constructing it by hand in a dish, you can 3D print it on the dish.”

BioLife4D says the bioprinted cardiac patches could bring significant cost and time savings by making the creation process scalable. The company, which has raised more than $1 million selling public securities, aims to eventually produce organs on demand.

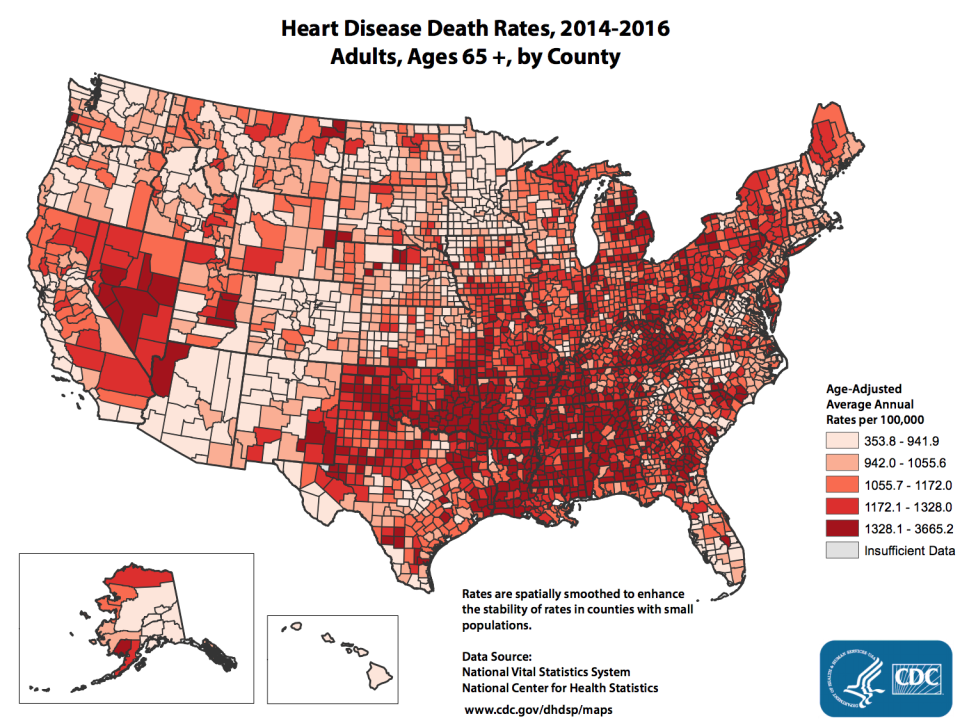

About 610,000 people die of heart disease in the United States every year, and 735,000 people suffer from heart attacks, according to the Centers for Disease Control and Prevention. In the developing world, the black market for organ trafficking generates somewhere between $840 million and $1.7 billion annually, according to a report by nonprofit organization Global Financial Integrity.

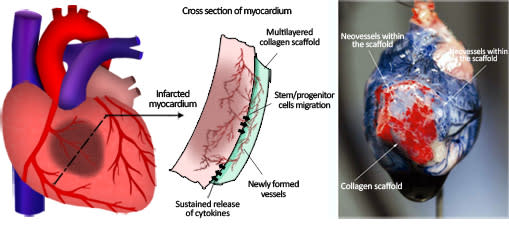

Cardiac patches

Woo explained that the idea of a cardiac patch is analogous to a patch on a tire.

“It’s sort of a kind of colloquial term to describe a tissue-engineered construct that is placed onto the heart to try to repair the heart. … A patch can be made of a variety of things, like a conglomeration of stem cells, or it can be a gel that has proteins in it that help heals the heart.”

BioLife4D stated that the cardiac patch, created at a research facility in Houston, is derived from a patient’s white blood cells and contains multiple cell types included in the human heart.

Woo, a spokesperson for the American Heart Association, noted that this development could bring material benefits to the industry by shaving off time spent to make the patches, increasing precision and adding stability.

“There’s an ability to change things very rapidly. You simply need to change out the ink and rewrite the program,” said Woo. “And cost — it’s labor intensive. When you’re switching from handmade to machine-made, there’s the capital expenditure of the machine and the labor cost.”

Aiming for human hearts

The ability to bioprint human cardiac tissue provides a “clear and rapid pathway towards bioprinting human hearts,” said Ravi Birla, PhD, BioLife4D’s chief science officer in a press release. The next steps will involve constructing parts such as valves, blood vessels, and a mini-heart. The company hopes that by using the patient’s own white blood cells, the company can eventually create a human heart that can be transplanted.

“What we’re talking about doing will solve the problem of supply and enable people on waiting lists to get hearts,” said Steven Morris, founder of BioLife4D. “Unlike a lot of other things that happen with medical advancements, this will be a win-win for everybody.”

However, Woo is skeptical of bioprinting a functioning human heart in the near future.

“There are a lot of organs that would be easier to print first, like the liver,” Woo said. “The liver has a more straightforward structure. … That would be an easier organ to print. The heart is a much more complex organ to synthesize than a liver or say a kidney, or the spleen or pancreas.”

Read more from Yahoo Finance: Map: What citizens around the world worry about most